I avoid using Simple Green on aluminum as I find that even at low concentrations it etches the aluminum.That is what I use for cleaning gun parts. Works great. It doesn’t completely remove the fouling from the surfaces but what it leaves is usually easily wiped away.

One caution of water based degreasers, it seems most of them are not safe for aluminum. The ones commonly mentioned, Simple Green, Zep Purple etc will all attack aluminum.

Even the purple simple green which is often said is safe for aluminum online, seems to cause a white powdery surface afterwards. They make an aircraft specific simple green that is branded as aluminum safe but I have not tried that one.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Parts Washer Solvent

- Thread starter thestelster

- Start date

Well, I think I'll try that Simple Green stuff. They make an Industrial Cleaner Degreaser, for about $30.00 for a gallon which will make 10gallons of solution. It's cheap enough and hopefully it will extend my life by another 20% It might even work!

It might even work!

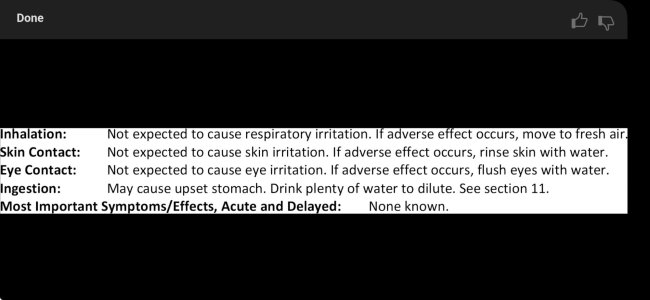

And looking at the MDS sheet,

"This product is not considered hazardous under 2012 OSHA Hazard Communication Standard (29 CFR 1910.1200)"

And looking at the MDS sheet,

"This product is not considered hazardous under 2012 OSHA Hazard Communication Standard (29 CFR 1910.1200)"

Attachments

Former Member

Guest

Just remember one thing about Simply Green, on the Space Shuttle used to be cleaned with liquid Freon prior to tile installation, along comes the Ozone issues and Freon is banned. The solution was Simply Green much to the dismay of NASA Engineers which begged for an exemption (and keep using Freon) considering the potential issues.

Needless to say sadly, the rest is history.

I have tried Simply Green and well the other solutions are better.

Needless to say sadly, the rest is history.

I have tried Simply Green and well the other solutions are better.

Doggggboy

Ultra Member

Are you saying that Simple Green caused the O-ring failures?Just remember one thing about Simply Green, on the Space Shuttle used to be cleaned with liquid Freon prior to tile installation, along comes the Ozone issues and Freon is banned. The solution was Simply Green much to the dismay of NASA Engineers which begged for an exemption (and keep using Freon) considering the potential issues.

Needless to say sadly, the rest is history.

I have tried Simply Green and well the other solutions are better.

Dabbler

ersatz engineer

I should hope that no one would make that inference. I have read the Space Shuttle report in its entirety, and have read a few of the subsequent follow-up papers by some prominent NASA engineers about it. The O ring failure was a result of multiple simultaneous failures across many areas, social, management, science, and engineering. To imply Simple Green caused the failure is very problematic.Are you saying that Simple Green caused the O-ring failures?

I would love to see an experiment with the 3 major types of O rings bathed in SG over time: rubber, nitrile and silicone to see if any of those are affected before making that association.

Former Member

Guest

No Simply Green caused the Tile Failures. The surface of the Shuttle was clean with Freon and then the tiles stuck on. With Simply Green the adhesive failed to adhere correctly because it failed to clean properly.

The O-ring failure was caused by forgetting how seals where made in the middle ages which was later adopted corrected the issue.

The O-ring failure was caused by forgetting how seals where made in the middle ages which was later adopted corrected the issue.

@kevin.decelles you have a bigger ultrasonic cleaner (2l)? How is that working?

I thought I read somewhere that the ultra sonic cleaners can etch the surfaces. What about parts that have a black oxide finish on them?The best cleaning method I’ve ever used on ferrous parts is an ultrasonic cleaner with a sodium hydroxide solution.

Oil, grease, paint, rust, aluminum, brass… it just eats it all.

After cleaning in the ultrasonic, rinse the parts with hot water and they are safe to touch.

Six O Two

(Marco)

I've had decent luck with Powerkleen degreaser from PA mixed at double the recommended strength for cleaning bicycle parts in my little 5g parts washer. Doesn't work quite as well as paint thinner on really heavily caked-on/soiled parts, but those I'll usually pre-treat with an oil-based cleaner.

As for gloves, I know you're dead-set against them, but I've had really good luck with the grease monkey 8 mil heavy duty nitrile gloves. Mine have stood up to the occasional wire wheeling and last pretty well for disposables.

As for gloves, I know you're dead-set against them, but I've had really good luck with the grease monkey 8 mil heavy duty nitrile gloves. Mine have stood up to the occasional wire wheeling and last pretty well for disposables.

ultrasonic cleaners will not etch parts, but the cleaning solution you choose could

Rauce

Ultra Member

I’m not sure if a caustic solution would remove black oxide. It does remove rust so maybe it would.I thought I read somewhere that the ultra sonic cleaners can etch the surfaces. What about parts that have a black oxide finish on them?

Canadium

Ian

How concentrated is your sodium hydroxide solution? Sodium hydroxide is what they use in oven cleaner in a pretty concentrated form. It's extremely reactive and can burn holes in your skin fast. Oven cleaner is my favorite ferrous parts cleaner even without an ultrasonic cleaner. In my experience tho some types of paint are more resistant to it than others.The best cleaning method I’ve ever used on ferrous parts is an ultrasonic cleaner with a sodium hydroxide solution.

Oil, grease, paint, rust, aluminum, brass… it just eats it all.

After cleaning in the ultrasonic, rinse the parts with hot water and they are safe to touch.

If it removes rust, it will take bluing right off since the two are quite similar chemically.I’m not sure if a caustic solution would remove black oxide. It does remove rust so maybe it would.

Rauce

Ultra Member

This was at my old job, we got it as a concentrated 50% solution and added it to water to bring it to probably 5% or so.How concentrated is your sodium hydroxide solution? Sodium hydroxide is what they use in oven cleaner in a pretty concentrated form. It's extremely reactive and can burn holes in your skin fast. Oven cleaner is my favorite ferrous parts cleaner even without an ultrasonic cleaner. In my experience tho some types of paint are more resistant to it than others.

Chemical resistant gloves and face shield when mixing the solution since the concentrate is of course very dangerous. On a couple occasions I got a little splash of the diluted solution on my arm and I could feel it but it didn’t leave a burn, I rinsed shortly after. I don’t think the diluted solution was any more dangerous than oven cleaner.

GlenG

Glen

That’s my go to for small gun parts as well. I use a Hornady one shot cleaner turn the heat up and it works like a charm.Try a small ultra sonic parts cleaner

That’s my go to for small gun parts as well. I use a Hornady one shot cleaner turn the heat up and it works like a charm.

Every once in a while someone on here says something I should know but didn't!

Thank you @GlenG !

I use a Lyman tumbler with crushed Walnut shells for polishing but just regular solvents for parts cleaning. I never knew Hornady made an ultrasonic cleaner. I'll be checking that out!

I like a lot of the tools that Hornady makes. I really like their seating depth gauge. But I don't buy their case gauges. I just make my own. By using a fired case I get a custom fit you can't even buy!

GlenG

Glen

I like Hornady as well but for cases have moved on to a Thumblers tumbler with stainless steel pins…. a lot less dust than walnut shells.Every once in a while someone on here says something I should know but didn't!

Thank you @GlenG !

I use a Lyman tumbler with crushed Walnut shells for polishing but just regular solvents for parts cleaning. I never knew Hornady made an ultrasonic cleaner. I'll be checking that out!

I like a lot of the tools that Hornady makes. I really like their seating depth gauge. But I don't buy their case gauges. I just make my own. By using a fired case I get a custom fit you can't even buy!

You can get a 2.5l ultrasonic cleaner for around $130 on Amazon which is what I have, but it looks like it came from the same factory as the Hornady .

Chicken lights

Forum Pony Express Driver

I like Hornady as well but for cases have moved on to a Thumblers tumbler with stainless steel pins….

I've had the best luck wet tumbling with stainless steel pins too, plus brass cleaner and some lemon juice

moved on to a Thumblers tumbler with stainless steel pins….

I confess I'm very leery of stainless pins. I want to clean my brass, not thin them. Stainless is harder than brass. So I suspect they are wearing the brass down to what looks gorgeously clean but is actually only new brass cuz the old surface is gone. Walnut is wood. It is softer than brass so it only removes the dirt and doesn't wear the brass. Admittedly it might not look as good.

Why am I worried about thinning my brass? Because I go to extreme lengths to turn my necks to a uniform perfect thickness +/- a tenth of a thou. I don't want any help making them thinner.

My other concern is work hardening my brass. That can be addressed by annealing them, but I prefer not to. Instead I keep track of how many times each case is fired and keep them all the same. When they show signs of hardening, I move them from first tier brass to second tier for hunting and casual shooting.

I was gunna press post on the above reply but thought perhaps I'd do some research first. I didn't find anything particularly to benchrest shooting, but I did find several guys who polished their nickel plated competition brass with the stainless pins. I have a few hundred of those old Federal Premium Nickel Plated Competition Brass from years gone by. But I don't use them anymore myself. Inatead I pretty much exclusively use Lapua Brass now. These nickel plated brass users found that the SS wore through the nickel plating. Keep in mind that nickel is even harder than brass. So, as I theorized above, it does wear the brass.

I guess it depends on how you use your brass, and what your expectations are. I'm a very anal retired benchrest guy. I go to extremes to make my brass as uniform and consistent as I possibly can. So I'm gunna stick with Walnut.

That's not knocking what others do just presenting a different perspective.