Jswain

Joe

I will have a look at it tomorrow/touch it up, and if I get the way covers on I will throw it in and try it out, Thanks!I think you will find that HSS is more forgiving than you might expect. I would not start over.

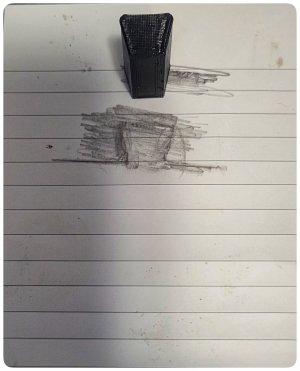

However, I do see an edge that might need a bit of work. To my eye, the side of the tip looks like it will rub as the tool advances into the work.

I've tried to highlight the problem but it's not a great markup. Just remember that the edge cannot be followed by a surface that sticks out more than the cutting edge.

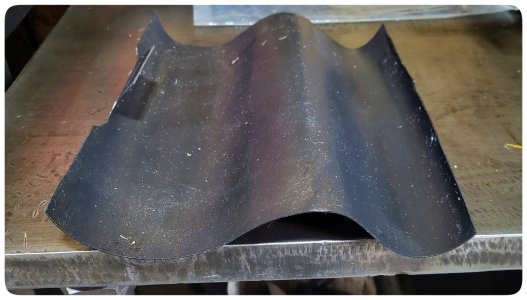

View attachment 44880

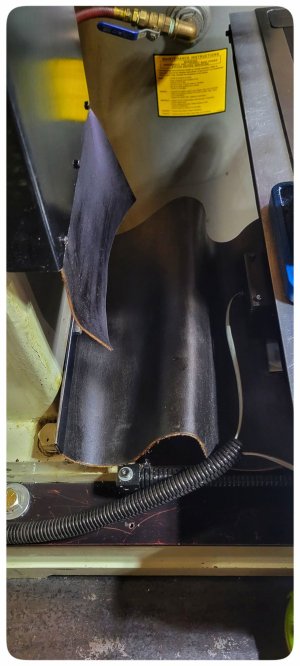

View attachment 44881