Yes I recognize that is all true.

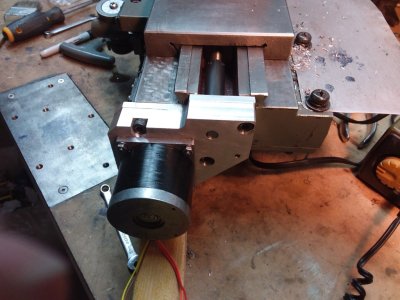

But in the end we are doing the project to convert our own lathes, which was to be our 12x37 and Brians 10x22, and the parts except drives would be common to a range of similar lathes, and we are not looking to be profitable business in this regard, just to serve interested people at the same time

Will there be long term support for ours, nope, but there will be enough to get those that are interested running...

Hell I see a ton of old commercial cnc machines on the market that are basically scrap because lack of support and parts.

Our goal is simple as possible smart lathe... aka servo lathe because homebuilt cnc lathes I've seen all ended up trash