I heartily agree; there is almost nothing so satisfying as watching a thick peel of metal coming off a sharp HSS bit.One other thing learning how to hand grind is a skill you should learn even if you abandon it later, again teaches you a lot about metals/tooling and edges.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What inserts do you like and why?

- Thread starter Susquatch

- Start date

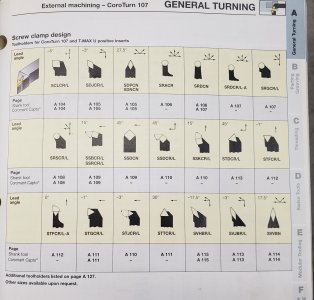

@Degen are you sure these inserts/toolholders are meant for general turning? The pocket (support) is aligned to suggest plunging like making a groove or fillet operation. I've also seen them in lathes used for profiling / blending, but usually CNC. Or facing mill heads in a mill setup.

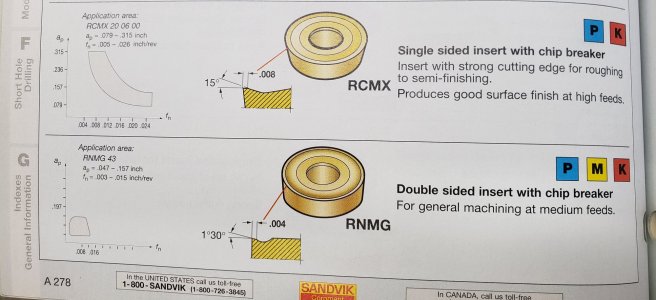

I have a 6mm insert / toolholder like yours. On my 303SS valves I tried turning the stems with the same tool since that also becomes the blend radius. It was not pretty. Significantly more load imparted to the part vs a smaller radius conventional cutter for the same DOC. I've tried the same cutter in other materials for finishing, aluminum & steel. Performs about as I expected. There was no advantage over conventional lathe inserts with say 1.5mm nose radius. I would not run a HSS tool of that equivalent 6mm radius (at least not on my 14x40) because the tool contact line is significantly longer than a conventional cutters even though is suppose the round insert is stronger. Hobby machines generally have less rigidity, lower HP, looser slide tolerances - usually a recipe for chatter.

I have a 6mm insert / toolholder like yours. On my 303SS valves I tried turning the stems with the same tool since that also becomes the blend radius. It was not pretty. Significantly more load imparted to the part vs a smaller radius conventional cutter for the same DOC. I've tried the same cutter in other materials for finishing, aluminum & steel. Performs about as I expected. There was no advantage over conventional lathe inserts with say 1.5mm nose radius. I would not run a HSS tool of that equivalent 6mm radius (at least not on my 14x40) because the tool contact line is significantly longer than a conventional cutters even though is suppose the round insert is stronger. Hobby machines generally have less rigidity, lower HP, looser slide tolerances - usually a recipe for chatter.

Attachments

little ol' e

Jus' a hobby guy

X2, then you have time to answer the phone and do a quick quote while its making a pass.I heartily agree; there is almost nothing so satisfying as watching a thick peel of metal coming off a sharp HSS bit.

Former Member

Guest

I have the others set ups as well, for heavy stock removal I use the larger of the 2 generally, the smaller one of mine is straight like @Susquatch and cuts left/right faces and in both directions very similar to a well ground HSS bit while allowing faster feeds (radius nose) maintaining a smooth finish compared to pointed bit. It has become my do all cutter on the lathe as it is one setup multiple choices for cuts and it leaves a nice stress free radius in the inside corners.@Degen are you sure these inserts/toolholders are meant for general turning? The pocket (support) is aligned to suggest plunging like making a groove or fillet operation. I've also seen them in lathes used for profiling / blending, but usually CNC. Or facing mill heads in a mill setup.

I have a 6mm insert / toolholder like yours. On my 303SS valves I tried turning the stems with the same tool since that also becomes the blend radius. It was not pretty. Significantly more load imparted to the part vs a smaller radius conventional cutter for the same DOC. I've tried the same cutter in other materials for finishing, aluminum & steel. Performs about as I expected. There was no advantage over conventional lathe inserts with say 1.5mm nose radius. I would not run a HSS tool of that equivalent 6mm radius (at least not on my 14x40) because the tool contact line is significantly longer than a conventional cutters even though is suppose the round insert is stronger. Hobby machines generally have less rigidity, lower HP, looser slide tolerances - usually a recipe for chatter.

View attachment 27924

Former Member

Guest

Same for carbide, just get to do mire cuts before sharpening/changing.I heartily agree; there is almost nothing so satisfying as watching a thick peel of metal coming off a sharp HSS bit.

Typical recommended speeds for carbide inserts I've seen bandied about the net are around 2,000 rpm. Considering my old lathe maxs out at 1200 I'm not sure why I'm even considering trying carbide inserts. If as @Susquatch points out the majority like myself are just hobbyists taking our time with limited resources why am I investing big bucks in a brand name QCTP that requires dozens of expensive tool holders, expensive carbide inserts and is better suited to inserts than HSS!? Why not just stick with the freeby old lantern toolpost which may be best suited to the HSS which my lathe is best suited and designed for?

The following is not a professional opinion. Just my own observations. I don't know where you are seeing typical speeds of 2000 rpm. In my experience, the ideal speed is usually expressed as surface feet per minute. The speed is only relative to the diameter. The bigger the diameter the slower the required rpm. Small diameters dictate faster rpm. FWIW, my lathe won't do 2000 rpm. 1400 is the fastest it goes. My mill will do 2720 from the factory and 4500 with my VFD (I'll never run that fast though).

For HSS, I have a nice Laminated wall chart that shows speed vs diameter vs materials as curves. I keep it on the wall behind my lathe. I don't really know if it's any good, but it works for me for HSS.

Diameter is on the left vertical axis, rpm across the top, and the colours are for material. I don't get religious about it though. I just pick a median number and then play with it up or down till I'm satisfied with the results.

On the other hand, most of the higher quality inserts come with recommendations for surface feet per minute (sfm) and feed rate. In these cases a calculation is required. I think the guys who do this stuff for a living just seem to know what speeds and feeds to use just looking at it. They have probably done the calcs so many times it became un-necessary to do it because they already knew what the answer would be. For stuff I do often, that's already the case even for a hobbiest like me. In fact, since I don't really have any really high quality inserts or holders yet, I have no factory recommendations to go by. So I have developed a sort of gut feeling about what works based on looking at the insert, the nose radius, and the edge sharpness. Those round inserts are pretty forgiving because they are sharp and have a huge nose radius. For the trigons I use for hogging, I crank everything up a few notches. Not nearly like @thestelster though. For me, even 40 thou is scary. I'm too old and too slow to do what the pros do. I get the job done though and in my world, that's all that matters.

I'm afraid that if I were honest I might admit that it's just because QCTP's and carbide inserts are sexier and nothing else!

I confess that I laughed so hard at this that I had tears running down my pantlegs! Truer words have never been said.

How many new lathe owners have not done exactly that? I know I did! It was one of my biggest mistakes. I would have been waaaay better off taking my time to buy what I needed and could use instead of the crap that seduced me.

I think BusyBee, and Grizzly, and King and and and, are all out there seducing us to buy these mostly useless kits.

That said, my newest lathe came with a BXA Quick Change Tool Post, so I didn't get sucked into buying that. And I also confess I like the QCTP. If I were talking to a new user who was considering a QCTP, I'd prolly recommend they go for it. And then buy more tool holders as needed. They come up on sale frequently and do make life easier for both HSS and carbide.

In my opinion and experience, the biggest difference between a QCTP vs a lantern post is stiffness. I think those lantern tool posts were horrible for stiffness. I lived with one for 30 years. I do not miss it. That doesn't mean I didn't do good work with it. I did! But I was constantly fighting chatter, poor finish, and decent cut depth. Parting was done with a hacksaw.

On the other hand I think those four sided tool posts are ok. If that is what had come with my newer lathe I might still be using it. The fact is that "quick change" is about convenience not function. As @Dabbler has said, an argument can be made that makes a 4 sided tool post faster than a QCTP in some circumstances.

So ya, I'd recommend a 4 sided tool post or a QCTP, but I don't recommend those economy tool kits. My own quest is to find the right tools to minimize my spending and provide the most flexibility and function.

are you sure these inserts/toolholders are meant for general turning? The pocket (support) is aligned to suggest plunging like making a groove or fillet operation. I've also seen them in lathes used for profiling / blending, but usually CNC. Or facing mill heads in a mill setup.

I have a 6mm insert / toolholder like yours. On my 303SS valves I tried turning the stems with the same tool since that also becomes the blend radius. It was not pretty. Significantly more load imparted to the part vs a smaller radius conventional cutter for the same DOC. I've tried the same cutter in other materials for finishing, aluminum & steel. Performs about as I expected. There was no advantage over conventional lathe inserts with say 1.5mm nose radius.

Peter - your question was not directed to me. But the picture you linked was mine not Degens.

I don't usually use those tools for plunge cutting but I have done it. I also don't use them for general cutting like degen said he did. Mine are mostly reserved for those times when I need a better finish. They do a great job of that for me. I don't know why your experience isn't the same. Perhaps you are taking too big a cut? I find the round bits cut almost as good as a shear tool. On shallow cuts, they almost seem to peel off a very thin piece of foil. The resulting finish is usually very good. I also run them a lot slower than one might guess for a carbide tool. That's what trial and error has done for me. That works for almost any material from stainless to 4140 to mild steel to brass to aluminium.

You are right though, they also work well if you need to contour a surface manually.

At any rate, unlike Degen, I don't consider them a general purpose insert. I will almost always reach for HSS or a Trigon insert for general purpose work.

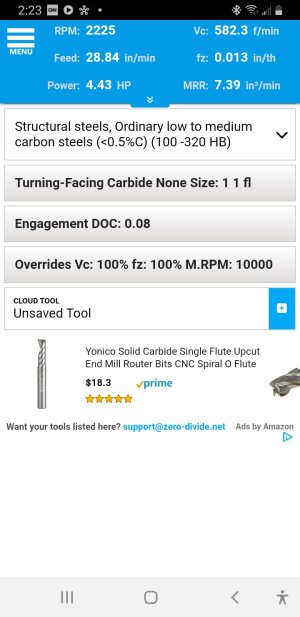

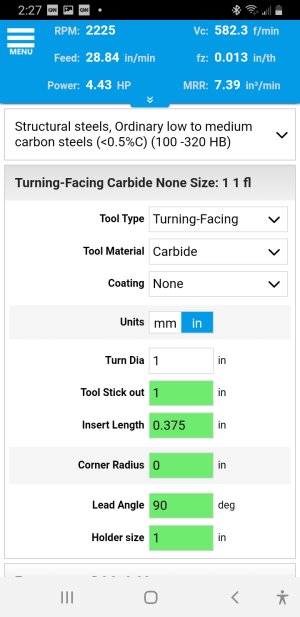

You really have to download the free FSWizard app. It will give you speeds and feeds for most machining operations, many types of materials and hardness you're working on, cutter material, coatings on the cutter, depth of cut, corner radius, tool stick out, and overrides. By overrides, I mean for instance, that the app might suggest using a particular speed or feed, and it tells you that it will require 5Hp for that cut, but you only have a 2Hp motor. Just go into the override to reduce the hp rating to what your motor is, and it adjusts the speed or feed. Or also to override for the maximum speed of your lathe or milling machine. I use this app almost every time I machine something (especially if I'm using HSS cutters or endmills or drill bits, to adjust for speed, otherwise they'll burn up. Carbide is more forgiving in the speed variance.) And you don't have to plug in all the variables, just the material you're machining, the cutter material, and the diameter, and you will have some good start values to use.For HSS, I have a nice Laminated wall chart that shows speed vs diameter vs materials as curves. I keep it on the wall behind my lathe. I don't really know if it's any good, but it works for me for HSS.

For those who are wondering, these are my two hogging tools for removing a lot of material fast - though not as fast as @thestelster ...... That man drives an F35 to work every day...... I have a Clydesdale.

I might help to understand that my main source of stock is old bolts - of all sizes and strength from little screws to massive 2" bolts with 6 pitch threads. So hogging is often standard procedure before I can get to the required work.

I might help to understand that my main source of stock is old bolts - of all sizes and strength from little screws to massive 2" bolts with 6 pitch threads. So hogging is often standard procedure before I can get to the required work.

Last edited:

You really have to download the free FSWizard app. It will give you speeds and feeds for most machining operations, many types of materials and hardness you're working on, cutter material, coatings on the cutter, depth of cut, corner radius, tool stick out, and overrides. By overrides, I mean for instance, that the app might suggest using a particular speed or feed, and it tells you that it will require 5Hp for that cut, but you only have a 2Hp motor. Just go into the override to reduce the hp rating to what your motor is, and it adjusts the speed or feed. Or also to override for the maximum speed of your lathe or milling machine. I use this app almost every time I machine something (especially if I'm using HSS cutters or endmills or drill bits, to adjust for speed, otherwise they'll burn up. Carbide is more forgiving in the speed variance.) And you don't have to plug in all the variables, just the material you're machining, the cutter material, and the diameter, and you will have some good start values to use.

Great tip! I shall do it right now! I like handy apps like that!

You really have to download the free FSWizard app.

It's installed. The very first barrier I hit is that it appears to be for milling. I know they can be related but it would be easier if I didn't have to do the conversion. Do you use something similar for your lathe?

I also noticed a Sandvik app when I was looking.

It's installed. The very first barrier I hit is that it appears to be for milling.

Hmmmmm, going back over this thread, it looks like lots of members are talking mills while others are talking lathes. Might be the cause of some of the confusion.

There's a box for "Tool Type", hit it and scroll to what you want to do.It's installed. The very first barrier I hit is that it appears to be for milling. I know they can be related but it would be easier if I didn't have to do the conversion. Do you use something similar for your lathe?

I also noticed a Sandvik app when I was looking.

There's a box for "Tool Type", hit it and scroll to what you want to do.

And so there is.....

Too many choices...... This is gunna hurt but prolly worth playing with it after my Clydesdale gets thirsty......

Click on the first banner beneath the blue upper section, and chose your material.

The banner below that is the type of operation, milling turning, drilling, reaming, threading, etc.

The rest are other parameters and overrides. The recommend starting data is in the upper blue banner. Make sure that the starting data HP is smaller than your motor. If not adjust the parameters in the override sliders until it is.

The banner below that is the type of operation, milling turning, drilling, reaming, threading, etc.

The rest are other parameters and overrides. The recommend starting data is in the upper blue banner. Make sure that the starting data HP is smaller than your motor. If not adjust the parameters in the override sliders until it is.

Attachments

Dabbler

ersatz engineer

@PeterT Th button inserts in post #122 can be used for hogging on *very* large machines. For a vid of someone doing this look at recent hydraulic cylinder rebuilds on youtube - Cutting Edge Engineering.

BUT Curtis is using a 15 HP or 20 HP lathe (he has 2) and each lathe weighs more than your shop, and he still gets chatter.

Using button inserts on a 3HP hobby lathe is limited to light cuts unless you are a 'machine abuser'.

BUT Curtis is using a 15 HP or 20 HP lathe (he has 2) and each lathe weighs more than your shop, and he still gets chatter.

Using button inserts on a 3HP hobby lathe is limited to light cuts unless you are a 'machine abuser'.

little ol' e

Jus' a hobby guy

@PeterT as well,

I use the button style inserts on the CNC lathe for the most part.

They do hog and produce nice surface finishes as Dabbler mentioned above.

They only time I would use them on a manual lathe would be if I have a quick 1 off shaft or bushing that needed grease grooves.

The cutter bodies come in another style for internal grease grooves as well.

This is what I use that style of holder and insert for on CNC, not so much for manual machining.

It takes a good amount of horsepower and torque to push this style cutter. That's why they don't work well for the hobby guys with smaller lathes with limited torque and horsepower.

Here are some pics,

I use the button style inserts on the CNC lathe for the most part.

They do hog and produce nice surface finishes as Dabbler mentioned above.

They only time I would use them on a manual lathe would be if I have a quick 1 off shaft or bushing that needed grease grooves.

The cutter bodies come in another style for internal grease grooves as well.

This is what I use that style of holder and insert for on CNC, not so much for manual machining.

It takes a good amount of horsepower and torque to push this style cutter. That's why they don't work well for the hobby guys with smaller lathes with limited torque and horsepower.

Here are some pics,

Last edited:

Peter - your question was not directed to me. But the picture you linked was mine not Degens.

I don't usually use those tools for plunge cutting but I have done it. I also don't use them for general cutting like degen said he did. Mine are mostly reserved for those times when I need a better finish. They do a great job of that for me. I don't know why your experience isn't the same. Perhaps you are taking too big a cut?

Fair enough. His post showed 2 toolholders with no further elaboration or distinction. The one on right looks like a neutral toolholder which is what I was referring to. I'm suggesting the toolholder pocket orientation & thinner shank under the insert is probably suited to mainly oblique or plunge orientation vs side load. Hogging or even heavy cutting is heavy sideload.

As for your second question, nope, the lightest of cuts. I just don't see the improvement over say a 1.5mm radii conventional insert toolholder. I can take a picture of a half thou shaving coming with a mirror finish using conventional insert but I don't really have a horse in this race. Use whatever gets you the results.

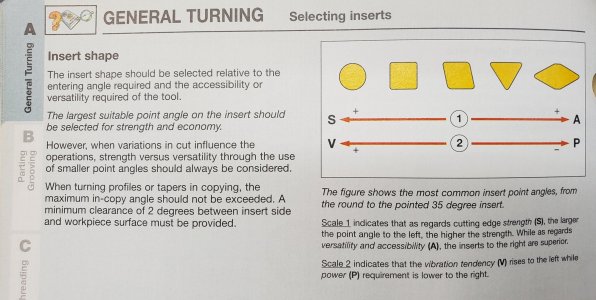

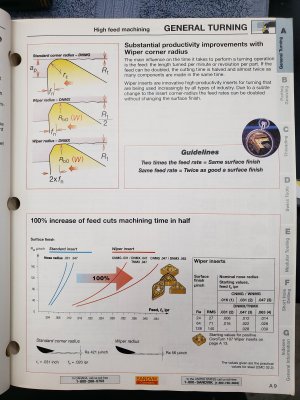

I'm trying to find some references (from insert manufacturers) that recommend a large radius or circular insert to be preferable for finishing cuts. Seems like what they call finishers come under variants of their conventional (faceted) inserts, with other geometric features, nose radii, rake, coating... variants. But I haven't looked too deep. Do you have some links?

Large diameter strikes me as counterintuitive. I mean if 6mm round insert makes a better finish than 1.5mm radii faceted insert, why stop there? Increase the radii to 10mm, 15mm? To me, its because diminishing returns and/or as contact arc increases, other factors enter the picture: rubbing, friction, heat, chatter, smearing... all anti-good finish attributes. The increased arc length is not like a mill cutter where the helix & turn orientation control chip thinning & other attributes. On a lathe, the entire profile is in contact with material.

How To Choose The Correct Carbide Inserts - Protool

The industry of cutting tools has expanded ten-fold in the last few years. Among hundreds of options, it is hard to choose the right tool. Selecting a tool that can produce low cutting forces with a good surface finish and the smooth cutting action is complex. Read this blog to learn how to...

Demystifying Insert Nose Radius Selection

Even among experienced machinists, choosing the right insert for boring a hole remains a difficult process that is fraught with myth and misconception. However, it is no myth that insert selection can completely save or kill performance on an application.

Attachments

Fair enough. His post showed 2 toolholders with no further elaboration or distinction. The one on right looks like a neutral toolholder which is what I was referring to. I'm suggesting the toolholder pocket orientation & thinner shank under the insert is probably suited to mainly oblique or plunge orientation vs side load. Hogging or even heavy cutting is heavy sideload.

Just to be clear, I do not (and never did) advocate heavy cuts with these round inserts.

As for your second question, nope, the lightest of cuts. I just don't see the improvement over say a 1.5mm radii conventional insert toolholder. I can take a picture of a half thou shaving coming with a mirror finish using conventional insert but I don't really have a horse in this race. Use whatever gets you the results.

I don't think I have any inserts with a nose radius that big (1.5mm). That's a pretty round nose (3mm diameter). I wouldn't be at all surprised to find that such a nose yields an excellent surface. Perhaps better than the round insert.

I'm trying to find some references (from insert manufacturers) that recommend a large radius or circular insert to be preferable for finishing cuts. Seems like what they call finishers come under variants of their conventional (faceted) inserts, with other geometric features, nose radii, rake, coating... variants. But I haven't looked too deep. Do you have some links?

I never said that manufacturers recommend this. It's just what I found from my own experimenting. Also, it's worth noting that ALL MY INSERTS ARE CHEAP CHINESE INSERTS. I don't have any really good ones yet. I don't have any good holders either. That's the whole point of my search for recommendations from other members. I have no stomach for buying and testing dozens of very expensive inserts and tool holders only to find that they don't work because because because. I think there are a lot of other hobby machinists who could benefit from the same advice.

Large diameter strikes me as counterintuitive. I mean if 6mm round insert makes a better finish than 1.5mm radii faceted insert, why stop there? Increase the radii to 10mm, 15mm? To me, its because diminishing returns and/or as contact arc increases, other factors enter the picture: rubbing, friction, heat, chatter, smearing... all anti-good finish attributes. The increased arc length is not like a mill cutter where the helix & turn orientation control chip thinning & other attributes. On a lathe, the entire profile is in contact with material

Well, it's not that I disagree. However, one could make the opposite extension of logic. I mean if 1.5 mm makes a better finish than 6mm, why stop there? Why not 1mm or 0.5mm? We all know that doesn't play out very well.

I don't think either logical direction holds water. Instead I expect that there is a sweet spot and furthermore that the sweet spot depends on a whole host of factors. For example, the one photo you attached shows a pretty aggressive depth of cut.

When I use round inserts for finishing purposes, my depth of cut might be 10 to 5 thou or even less. So the cut does not involve the entire radius - only a very small arc of it.

For the best finishes, I don't use the round inserts either, I use a hss shear tool. And of course, it all depends on what you are after.

Anyway, this is turning into a bit of a defense of my own use of round inserts and that isn't the purpose of this particular thread (I am the OP). The purpose is to ask others what they use and why.

I would like to get some good input on what you use and how it works out for you.

Do you use the same insert with many holders to achieve versatility?

Do you maintain a stock of a particular insert with different nose profiles? Different coatings?

Etc etc.