Just a few additional observations.

As far as I have seen, there are no plates with 540 holes, so there are no plates with 1 minute resolution. Yet, the regular crank handle on my RT will resolve 1 minute - with near zero backlash! There is wayyyy more backlash and error using those plates........ So why are they so popular? Surely it can't be just the convenience!

Dividing plates are mostly a convenience to position the chuck/table/whatever 'output' to some target angular increment. For example if I need to cut a 27 tooth gear, I can:

1) mount the plate which has a 27 hole circle, crank (1 turn + 13 holes), cut the tooth, rinse & repeat.

2) turn the RT wheel the exact amount. So 360/27= 13.333333 degrees, so crank to 13-deg plus corresponding degree-minute-second graduation to 0.33333 remainder. Cut the tooth, then repeat that 26 more times without a math error or inadvertent division slip up.

On simple, nominal divisions it might be quicker to use the RT dial but that's because the graduation readily aligns. On more complex combinations, as long as you can count & stick it in the hole (LOL), it removes the math. So the fact that an interim hole division happens to works out to some very fine angular remainder (what you all resolution) is just a secondary artifact of the math, not really the purpose of the plate IMO. So the likely reason is there are no super high hole count plates is a) hard to fit that many holes on a small diameter plate b) equates to gears or splines that are so fine they are generally uncommon in most everyday mechanisms.

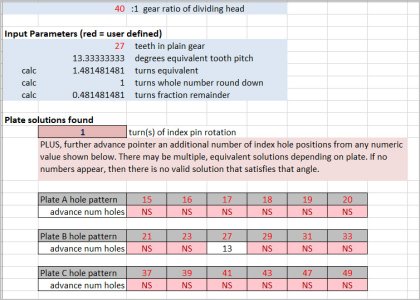

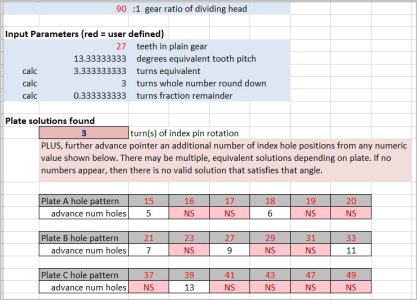

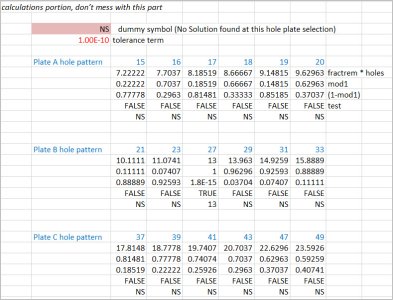

Been a long time since I looked at this stuff, but I wrote a spreadsheet where I can input the gear ratio & the desired tooth count (or angle which is related) & it spits out the plate/hole combination. There are tables on the internet but I wanted to figure it out. So a few things are evident. The gear ratio & plate must be known because they work in conjunction with one another. A 40:1 will have a different hole combination than a 90:1. And different plates may yield the same angle with different hole combinations. And some tooth count/angle combinations are not possible because non-evenly divisible. And I guess if you ever wanted to use a different worm/gear/plate combination, maybe there is a new & exciting gear tooth you could achieve! LOL

https://cdn.shopify.com/s/files/1/0424/4249/0019/files/Final_-_Combined.pdf?v=1623448375

Lastly, I think backlash is backlash whether you are using method 1 or 2. You must always advance in one direction. You can pause but you cannot overshoot & backup, otherwise backlash is introduced. If you go slightly past the target hole on a plate & then jiggle it in, that's technically a no-no. But no different than inadvertently going past the target dial increment & reverse creeping to the target.