Is that outside or inside?73% humidity today

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Magnetic parallel holders, $15, Windsor, ON

- Thread starter JustaDB

- Start date

OutsideIs that outside or inside?

Ironman

Ultra Member

Right you are.Seems kinda gimmicky to me. As if standing a parallel up is too darn challenging......

I use squares of the closed cell foam blocks that come as packing around things I buy. They are put between the parallels and compress as you tighten the vise and a re reusable, they are free and a 2x8" block will give you enough custom cut pieces to last a year or two.

ChazzC

Ultra Member

Thanks to @jcdammeyer & @Janger !

Unfortunately, the magnets I have are too large for the 4" version, and looking at the drawing even 4" would be longer than practical for my 3" parallels (and the combined thickness/width of the holder & parallel wouldn't be practical for my 4" chucks – and marginal for my shiny new 5").

However, I did have a Eureka moment (otherwise know as a Brain Fart) while lamenting this reality and came up with this solution:

Although the magnet on the long leg of a MagKeeper does not extend through the leg, it is strong enough to hold the MagKeeper to steel through the Aluminum body, and the (smaller) magnet on the short leg does go through that leg. A pair of MagKeepers is perfect for holding a parallel on the face of a chuck (5/8" parallel on a 4" chuck, above), and removing the "Keepers" and parallel prior to spinning up is easy. Problem solved (for me, at least). Without this discussion I never would have thought of trying this (I've had them for 4 years) – thanks again to all.

Unfortunately, the magnets I have are too large for the 4" version, and looking at the drawing even 4" would be longer than practical for my 3" parallels (and the combined thickness/width of the holder & parallel wouldn't be practical for my 4" chucks – and marginal for my shiny new 5").

However, I did have a Eureka moment (otherwise know as a Brain Fart) while lamenting this reality and came up with this solution:

Although the magnet on the long leg of a MagKeeper does not extend through the leg, it is strong enough to hold the MagKeeper to steel through the Aluminum body, and the (smaller) magnet on the short leg does go through that leg. A pair of MagKeepers is perfect for holding a parallel on the face of a chuck (5/8" parallel on a 4" chuck, above), and removing the "Keepers" and parallel prior to spinning up is easy. Problem solved (for me, at least). Without this discussion I never would have thought of trying this (I've had them for 4 years) – thanks again to all.

I see. So prolly a lot dryer inside then.Outside

Around here, winters are so dry INSIDE that we get nose bleeds and so wet in the summer INSIDE that sweating doesn't help. We use Dehumidifiers all summer and humidifiers all winter.

Filament should be as absolutely dry as possible. And RH is relative... ha ha.I see. So prolly a lot dryer inside then.

Around here, winters are so dry INSIDE that we get nose bleeds and so wet in the summer INSIDE that sweating doesn't help. We use Dehumidifiers all summer and humidifiers all winter.

Dew Point Calculator

This free dew point calculator calculates dew point, relative humidity, or air temperature if given any of the other two values.

Start with 25C and 45% RH and raise temperature to 50C and RH drops to 11.55% plus the air has expanded a bit. Thing is, if I understand this correctly, the air and water molecules inside the filament are still really at the 45% RH level. Over time at 50C they migrate out to ambient bringing the RH inside the filament down to closer to that 11.55%.

Now when it goes into the nozzle for printing and is brought up to 205C there's much less moisture to snap crackle and pop making the resultant print much smoother.

PLA is particular susceptible and also becomes hard with the absorbed moisture making it more likely to break which is why a filament detector is useful.

140mower

Don

One thing that the coast offers up that you miss out on, is that the storms put a lot of salt into the air. Cars just love that.....I see. So prolly a lot dryer inside then.

Around here, winters are so dry INSIDE that we get nose bleeds and so wet in the summer INSIDE that sweating doesn't help. We use Dehumidifiers all summer and humidifiers all winter.

Just means that the MacDonalds Fries taste better with that extra salt...One thing that the coast offers up that you miss out on, is that the storms put a lot of salt into the air. Cars just love that.....

Hmm we don't worry about things in the air here in Saskatchewan until dry old summer. That swirling alkali dust gets into everything.One thing that the coast offers up that you miss out on, is that the storms put a lot of salt into the air. Cars just love that.....

That is pretty slick John, any issue stuff getting magnetized? parallels or even the vise?

Not at all as convenient, but an old school way is a couple of die springs zip cut to the right length between the parallels. I've done when there are lots of parts to do.

Picture making 10 parts, swapping them in and out of the vise. If the parallels aren't held in place, every time they move you have to pull 'em out and clean else there could be a chip under them. This (at least when i''ve done the same with die springs) keeps everything in place, no chips get under the parallels and things go a lot faster

Not at all as convenient, but an old school way is a couple of die springs zip cut to the right length between the parallels. I've done when there are lots of parts to do.

Seems kinda gimmicky to me. As if standing a parallel up is too darn challenging......

Picture making 10 parts, swapping them in and out of the vise. If the parallels aren't held in place, every time they move you have to pull 'em out and clean else there could be a chip under them. This (at least when i''ve done the same with die springs) keeps everything in place, no chips get under the parallels and things go a lot faster

Start with 25C and 45% RH and raise temperature to 50C and RH drops to 11.55% plus the air has expanded a bit.

You have the gist of it John. Close enough as they say. But the psychometric chart has other tricks up its sleeve. You chose 20 and 50. But - 5 and 20 are more realistic for this part of Canada. Your link calculates dew point. I was going to provide a link to psychometric chart which is somewhat complicated to use, but in the process I found this one which does exactly what we are after. Plugging in an outside temp of -5C, an outside humidity of 45%, and an inside temp of 20C we see that the relative humidity inside dives to just 9% inside.

So you should be able to keep your filament open to the room in the winter.

You are correct about how the filament humidity itself is much slower to react than the air is, but water molecules are pretty small and should be able to migrate out of the filament pretty quickly. I'd guess a few days should do it. If you think about it, all that a special filament dryer box does is dehumidify the air inside the box to do the same thing.

I think filament drying could be solved with a cardboard box solution? You would want the walls to be water vapour impermeable. Is there a solution already?You have the gist of it John. Close enough as they say. But the psychometric chart has other tricks up its sleeve. You chose 20 and 50. But - 5 and 20 are more realistic for this part of Canada. Your link calculates dew point. I was going to provide a link to psychometric chart which is somewhat complicated to use, but in the process I found this one which does exactly what we are after. Plugging in an outside temp of -5C, an outside humidity of 45%, and an inside temp of 20C we see that the relative humidity inside dives to just 9% inside.

So you should be able to keep your filament open to the room in the winter.

You are correct about how the filament humidity itself is much slower to react than the air is, but water molecules are pretty small and should be able to migrate out of the filament pretty quickly. I'd guess a few days should do it. If you think about it, all that a special filament dryer box does is dehumidify the air inside the box to do the same thing.

I think filament drying could be solved with a cardboard box solution? You would want the walls to be water vapour impermeable. Is there a solution already?

To answer that, I'd need to more about the filament's water absorbtion chemistry.

I figure it's just plain old humidity absorption. So a Dehumidifier box doesn't need to have a vapour barrier, although a barrier might speed up the process.

On the other hand, if the issue is storage, then it would need the barrier as well as a dessicant or dehumidifier. Prolly better off using a waterproof plastic box with an O-ring seal and throw in some dessicant.

It does both. Clear out the temperature field and set dewpoint and RH and press calculate and you get temperature.Your link calculates dew point.

What's -5C. I think I've heard of that once or twice this year. It's supposed to be cold right?Plugging in an outside temp of -5C, an outside humidity of 45%, and an inside temp of 20C we see that the relative humidity inside dives to just 9% inside.

I have a dehumidifier in the shop. The type with the compressor and I find it's pretty easy to see it at 45%. But again the RH isn't important. The dew point temperature will tell me what the heater has to be set at to maintain the iron about 10C above that. One year, when I didn't pay attention, I suddenly had rust on everything.So you should be able to keep your filament open to the room in the winter.

You are correct about how the filament humidity itself is much slower to react than the air is, but water molecules are pretty small and should be able to migrate out of the filament pretty quickly. I'd guess a few days should do it. If you think about it, all that a special filament dryer box does is dehumidify the air inside the box to do the same thing.

The filament driers are just heaters with a fan that take in a certain amount of air and blow out heated air. Similar to the setting your more modern oven has for dehydrating fruit etc.To answer that, I'd need to more about the filament's water absorbtion chemistry.

I figure it's just plain old humidity absorption. So a Dehumidifier box doesn't need to have a vapour barrier, although a barrier might speed up the process.

On the other hand, if the issue is storage, then it would need the barrier as well as a dessicant or dehumidifier. Prolly better off using a waterproof plastic box with an O-ring seal and throw in some dessicant.

Now if you drop the temperature to or below the dew the air can no longer hold the moisture so in condenses out as fog or even rain. That's why we see out breath which has a certain water content at 37C. If the air it mixes with is cold enough it can't hold the water and it condenses out.

Now if you drop the temperature to or below the dew the air can no longer hold the moisture so in condenses out as fog or even rain. That's why we see out breath which has a certain water content at 37C. If the air it mixes with is cold enough it can't hold the water and it condenses out.

Yes, I explained all that way back in my rust is the enemy thread.

Rust is the Enemy

Thought you folks might like to see what that salty air does to copper/brass. This is what happened to steel. Keep in mind that happened in an enclosed cupboard. Might not happen in open air.

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

I've also explained it elsewhere.

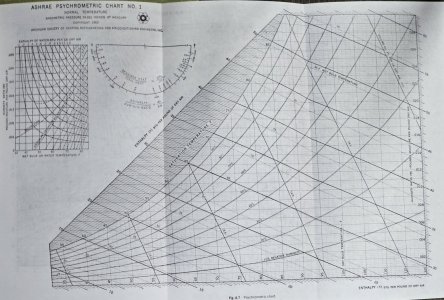

I think most people separate humidity, corrosion, dessicants, dehumidifiers, dew point, and soggy filaments as though they were each a unique process, when they are not. It's all about how much water a given volume of air can hold at a given pressure and temperature. The amount of water in there vs the maximum amount of water that could be in there is the percent relative humidity. The lower the percent, the drier the air and vice versa. It's all defined very precisely by psychometric charts like this one:

How-To Guide: How To Use a Psychrometic Chart - Parameter

Learn how to use a psychrometric chart and draw conclusions between supply air and relative humidity by downloading our free psychrometric chart PDF.

humiditycontrol.com

humiditycontrol.com

Or this one from one of my many engineering thermodynamics text books.

In this case regarding filament storage and filament dryers. It's a fair bit simpler.

Basically, if the goal is the driest filament possible, then dessicating it should be done at higher temperatures, with low relative humidity established by a dehumidifier.

If the goal is storing it and keeping it dry assuming its already dry, then one of many good alternatives is to just put it into a water tight container filled with cold dry air. This can be easily done by putting the filament into a sealable box and then scooping some cold outside air into the container or even dunking it into a floor chest freezer to let cold air spill into the container. Close the lid but not too tightly, then set it on the shelf in your work area to let the air temperature stabilize. Then seal the lid solidly till you need some filament. Rinse and repeat as you need more filament.

The idea is to take advantage of the fact that cold air holds very little moisture, and as it warms up, the relative humidity will dive.

Of course, as air warms, it also expands so the lid can't be sealed tight until it is warmed up enough that it won't burst. The air leaving the container does no harm and actually serves to leak a little water too.

There are also many good sources of bulk dessicants. These can often even be recycled.

Maybe related if I understand discussion. My friend was showing me a kit he bought online. What looked like large Ziplock bags with integrated a flapper/check valve vacuum type fitting, a simple manual plunger vacuum pump & another bag of desiccant packets. I think the idea is put your spools in there & that preserves them?

ChazzC

Ultra Member

On the other hand, if the issue is storage, then it would need the barrier as well as a dessicant or dehumidifier. Prolly better off using a waterproof plastic box with an O-ring seal and throw in some dessicant.

I keep my filament (mostly HIPS) in 5 gallon plastic pails with screw-on lids. A dehumidifier cartridge & small humidistat live in with the filament. Have never had any issues.

I keep my filament (mostly HIPS) in 5 gallon plastic pails with screw-on lids. A dehumidifier cartridge & small humidistat live in with the filament. Have never had any issues.

I love it. The only problem with a 5 gal pail is filling it with cold air. But if the dehumidifier and humidistat are there, the cold air dunk isn't needed.

Printing with HIPS? I had to look it up. https://www.3dsourced.com/guides/hips-filament-3d-printing/I keep my filament (mostly HIPS) in 5 gallon plastic pails with screw-on lids. A dehumidifier cartridge & small humidistat live in with the filament. Have never had any issues.

High impact poly styrene, strong, but easy to print. Toxic fumes similar to ABS. When paired with ABS and using HIPS as the support material the HIPS can be dissolved away with a wash. Interesting.

You can see how HIPS compares with the chart in this article: https://blog.prusa3d.com/advanced-filament-guide_39718/

What made you choose this filament @ChazzC ?