I would be interested in more details on your pulley setup

Curious on how the 3d parts attach to the shafts with sufficient strength

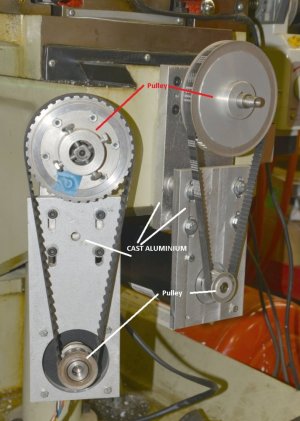

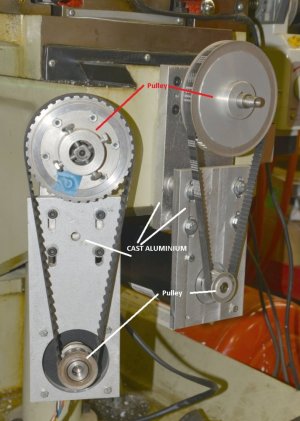

The upper horizontal shaft to the bevel gears had the bushings replaced with ball bearings at both ends since pulley drive stresses in one direction. The ball bearing mount at the bevel end also took out more of the end play but there is still some backlash.

The original pulley I used with the stepper motor used 4 screws to clamp onto the 4 sides of the square handle drive part.

The stepper motor just had a flat for the driving pulley setscrew. The 3D printed version still has the 4 screws but I printed the square hole and it's a nice firm sliding fit onto the square shank. The screws now just hold it in position. Yo.u can see that in the previous photo of the setup. If you want I can make a closeup photo of it.

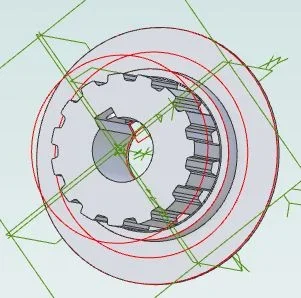

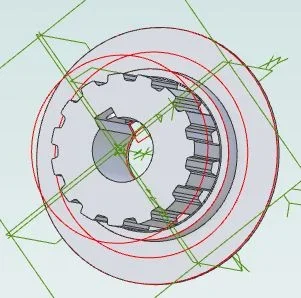

The new motor is 19mm with a 6mm key so I 3D printed at 15T pulley that has a large enough ID for the 19mm hole and 6mm key. I then reamed and broached the key channel with the broach to make it fit the motor shaft and a set screw through a raised tooth holds it tight.

I 3D printed a second flange for the front and glued it in place.

These are the left over bits and pieces after all that.

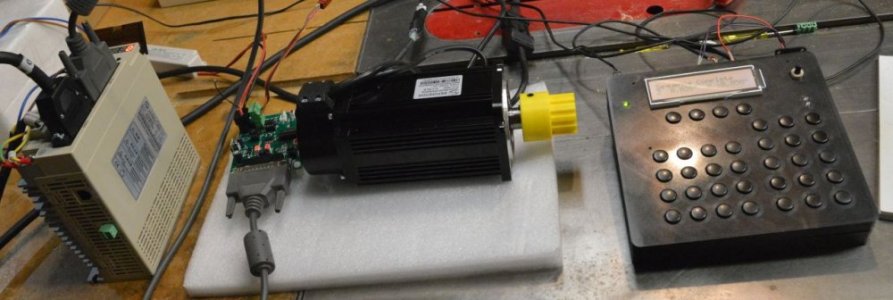

Had I procured the Bergerda Stepper drive first (which didn't take any longer than Prime) I'd not have gone through it all. You can see the size of the heatsink difference in the photo. And it's just better built for only a few dollars more. Even $20 more would still be $60 less than the Gecko it replaced. Notice too on the Bergerda the connector for the control signals is a different size from the stepper/power connector so there's no chance of accidentally plugging power into control which is possible with the Stepperonline.com product.

I did want faster knee travel so in the long run changing to the Bergerda AC Servo will be a good thing. But so much extra work.

The other up side of changing to the Bergerda AC Servo is I already have 220VAC in the cabinet so I can totally get rid of the huge toroid etc. used to power the single 1200 oz-in stepper.