So now your spider is aligning the part so both end diameters are clocked perfectly concentric to spindle axis. But you cant control a distorted bore path like you were saying. Why should a deep re-drill or reamer now follow a straight path? Why wouldn't it be heavily influenced by existing bore and largely follow along any deviation? How do you quantify deviation & bore diameter before & after the re-dressing operation?

View attachment 15492

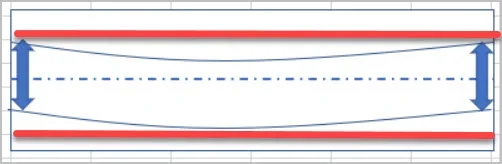

Your drawing is incorrect at both ends.

Although this is a gross exaggeration of what things really look like, hopefully it will help you see the situation better.

The axis of the bore at the work end is what matters. It must be aligned with the axis of the spindle. In the drawing, even the face of the barrel at the right side is not square to the axis of the inside bore. It must be faced off square as the first step of any subsequent work. All indicating and alignment is done at the right side where the work will be done. The left side is only positioned (not centered) such that the right side is both centered AND aligned.

Why wouldn't it be heavily influenced by existing bore and largely follow along any deviation?

You are of course correct, it is HEAVILY influenced. But not TOTALLY influenced. In the pursuit of perfection, HEAVILY is not sufficient. To help achieve perfection, we do everything we can to make sure we are as close to perfect as possible.

There is no need to quantify deviation & bore diameter before & after the re-dressing operation. The end results and performance of the finished work is what matters.

Last edited: