This thread has been a very interesting read for me. I'd like to add just a few comments.

As

@historicalarms has said, barrels often end up drilled off center. Although I've never seen one that is 1/4" off - Holy Moses!!! Maybe it was before the barrel maker cut the barrel contour though. I've also never seen one that was straight. Not ONE! Every single one I've ever seen has had a bit of an arc to the axis. That's why I prefer to chamber through the headstock with a spider on both sides of the head to deliberately offset the back end and precision align the working end such that the axis of the end I'm working on (muzzle or chamber) is truly concentric to the spindle axis. Others may use other methods successfully, but mine works for me at competition worthy levels.

As

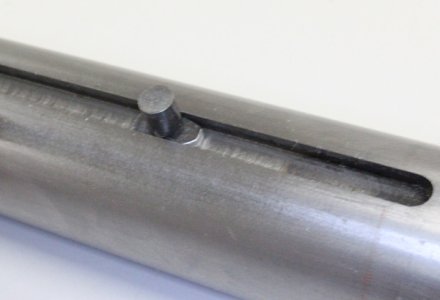

@Dabbler has said, all my chambering end work has been done with precision fit (+/- 0.0001 yes a tenth of a thou) bushings to guide the finish or roughing reamer or drill in the bore on the lands with a floating reamer holder. I let the Bushing establish the course.

Although I absolutely love the creativity of the idea itself that was first pointed out by

@YYCHM, I could never imagine doing any chamber work using that method.

@Brent H posits that it's only 3", but for my chambering work, I take his point to the extreme. Depending on the steel and chamber size, I usually cut just 25 thou at a time at the slowest speed I have, then pull the reamer out, clean, relube, and repeat. I also always hold the reamer holder in my left hand while I rotate the tailstock quill advance so I can feel the reamer cutting and thereby have a good feel for what is happening in there. It's a lot of repetition and it's very slow going, but my results speak for themselves.

I really do want to thank

@YYCHM for showing us the idea. I may never use it, but I am always fond of growing my Basket of Tricks and my how-to knowledge base.

I love this forum.