Here is a couple of thoughts:

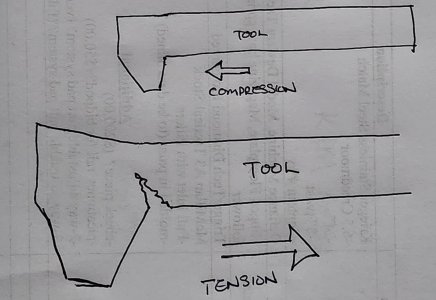

Moving the tool in the one direction the forces acting on the cutter is compressive.

Going in the other direction the forces on the cutter is tension. And breaks at the corner. Plus carbide is very brittle as we know.

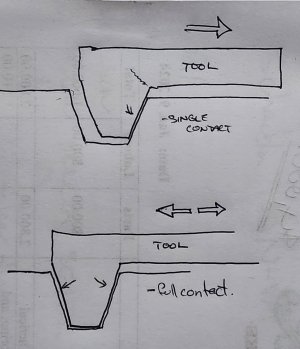

When I was plunging into the work, the threading tool is completely supported on the leading and trsiling edges.

But when I started to move axially, it created a gap at the trailing edge which allowed the cutter to flex at that inside corrner of the tool.

Moving the tool in the one direction the forces acting on the cutter is compressive.

Going in the other direction the forces on the cutter is tension. And breaks at the corner. Plus carbide is very brittle as we know.

When I was plunging into the work, the threading tool is completely supported on the leading and trsiling edges.

But when I started to move axially, it created a gap at the trailing edge which allowed the cutter to flex at that inside corrner of the tool.