-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cool Tools in your home shop that you'd not likely not see in someone else's?

- Thread starter Elektrishun

- Start date

TorontoBuilder

Sapientia et Doctrina Stabilitas

I have one.I wanted to make a small home security device that would produce the sound of a shell being racked into the chamber of a 12 ga.

But I couldn't manage to make it smaller despite a few years of trying. So I'm pretty much stuck with a model that is 5'10" tall and 185 pounds. Other than the size issue the device functions perfectly at producing the sound of a shell racking into the chamber of a 12 ga.

With a slight change it can also replicate pretty much any other gauge you'd like

I also used one of them the other day to push a crack closed on a casting I was repairing. Clamped one side of the casting down to the table, put a clamp lightly on the other side to constrain it, and clamped the hold down to the table. Made it really easy to apply force on an awkward part, without a clamp in my way while I welded the part.Sometimes the obvious is not obvious. Well not at first.

I have a pair of TE-CO toe clamps. (Thanks to @Stuart Samuel for putting me in contact with the seller during our Forum spring meet-up)

View attachment 55420

I tried them on the mill to hold a a large flat piece of steel. They worked great but that exercise made we wish i had another pair so i could clamp from 2 directions or locations.

A light went on this morning when i saw this picture (from Darren’s post above).

View attachment 55421

Oh so obvious - just clamp down a backstop and then use one of these to clamp towards it (just like a 2 piece vise).

Wow - Just overcame another brain fart!

I have nothing too crazy got some of neat stuff I've found over the years. Tiny hammer for tiny trouble shooting. Same as my 13/64 wrench for those hard to reach nuts.

I got this 6" shell mill that I'm gonna use on my mill when I find 2" 40 taper holder

for it lol.

Not sure if it counts but I don't imagine many people have a homemade sphere machine laying around.

O ye last but not least I got a small optical flat from USSR

I got this 6" shell mill that I'm gonna use on my mill when I find 2" 40 taper holder

for it lol.

Not sure if it counts but I don't imagine many people have a homemade sphere machine laying around.

O ye last but not least I got a small optical flat from USSR

KeeponDragon

no problems... just challenges

I can only assume it makes spheres by spinning those cups over the workpiece...as the workpiece rotates?

ornamental concrete bra filler?

ornamental concrete bra filler?

Not sure if it counts but I don't imagine many people have a homemade sphere machine laying around.View attachment 55456

Basically ye the cups do the cutting and the action of the rock to turning random patterns makes it round. If rock gets stuck or makes repeating patterns you get weird looking shapes.I can only assume it makes spheres by spinning those cups over the workpiece...as the workpiece rotates?

ornamental concrete bra filler?

Ehhh just thought it would be neat and the wife is into lapidary so figured why not make one and screw around. Makes fun little gifts to throw at people.

Attachments

Nice build!homemade sphere machine

My Dad would have loved that. He was into petrology and lapidary for many years. I'm guessing the cutting is by the rotating diamond cups that are flooded with water, The water drains into the tank below (the tire) and is pumped back up.

Interesting .....

I used diamond core drill segments and silver soldered then onto some cast iron cups for the roughing cupsNice build!

My Dad would have loved that.

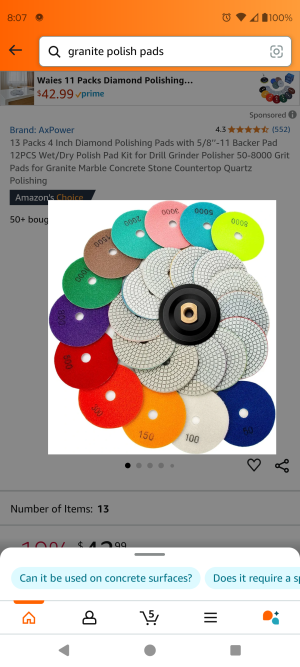

And for polishing I cut up some diamond resin pads for counter top resurfacing and glued them to more pipe fittings. I need to get the wife to 3d print a cup set I can glue velcro too so I can just modify the pads and then just use same cups not have bunch of cups I go to switch every stage.

There is sphere machines that use a slurry with grit to do all the cutting and polishing but they are bit slower and usually use a chain that sits on sphere and one of the cups and the slurry kinda clings to chain and makes its way onto sphere.

The tire was just something convenient to set the machine on and I have a garden house rubber banded to one of the motors and just cracked the valve to drop feed sphere during polishing. Roughing I just run dry.

Attachments

Dan Dubeau

Ultra Member

My Son really wants to build one of those. It's down the project list a ways, but eventually might get to it.....

It's pretty fast build less then 6 hours I would guess and biggest part cost is the motors are around 100$ a piece. The other big cost is the cups.My Son really wants to build one of those. It's down the project list a ways, but eventually might get to it.....

Depending on if you make em or buy them pre made. If I were to budget to build another one including buying premade cups and polishing pads I would budget around 800$ and that should get you well set up for making 2"-4" spheres.

Only draw back is your limited to the size of your cups for what you can make.

The other thing that effects cost is size of spheres you want to make to begin with I made this unit for around 120$ as a prototype but ordered too small of motors for it to be useful for anything but polishing really.

Or if you wanted to get crafty you can make use of the plethora of outdated 12v drills available for less then 20$ a pop or maybe get few for free from e waste drop off.

DIY Sphere Machine | Rock Tumbling Hobby

Now that winter has set in here in the Pacific Northwest and I'm stuck inside, I decided to build the next machine on my list. I've been meaning to build a sphere machine for a year or two now,

Attachments

Wife just asked what I was looking at, a guy talking about polishing his balls said I. Now I get the stink eye, women never understand.

My bride wants a link.

Round ish doesn't have to be perfect but if too out of round it has tendancy to jump out of cups. I kinda just shape the rocks with tile cutter then rough a bit then remove any lumps with diamond zipcut then just check with calipers so make sure rock isn't turning into egg shape or something weird.The work must be fairly round to start with? Presented with a rock, how do you get it to the point of loading in the polisher?

Not fool proof tool and does require bit of babysitting during roughing.

Used to cut tightly compressed powdered high explosives to inspect for voids and/or striations in the finished product.

Ya, but what do YOU use it for?

You reminded me of something I have. Material, not a tool, but probably not kicking around most shops.Diamond coated wire

Used to cut tightly compressed powdered high explosives to inspect for voids and/or striations in the finished product.

View attachment 55506

Platinum wire, ~0.005 diameter.

Inherited from my Dad, apparently they used it in printers or photocopiers at some point (He spent 40+ years as a Xerox technician).