-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Compressor Question

- Thread starter YYCHM

- Start date

It almost sounds like your check valve is faulty or somehow inverted or tube issue - something not allowing air to flow into tank normal? As soon as the piston sees any appreciable pressure build which would happen rapidly +/- some blowby & tube fill-up, it dead heads & locks up. That would explain low 20 psi pressure, breaker going & wheel locking up. Any way to just (safely) flow it through a regular hose into your spare tank with gauge to temporarily remove the check valve from flow circuit?

It almost sounds like your check valve is faulty or somehow inverted or tube issue - something not allowing air to flow into tank normal? As soon as the piston sees any appreciable pressure build which would happen rapidly +/- some blowby & tube fill-up, it dead heads & locks up. That would explain low 20 psi pressure, breaker going & wheel locking up. Any way to just (safely) flow it through a regular hose into your spare tank with gauge to temporarily remove the check valve from flow circuit?

The check valve is functioning properly. If I discharge to atmosphere through the check valve you can is it pop open and it stays open until I kill the power and then it pops closed. You could run this thing all day like that with out an issue. It's as if the head can't tolerate to see any back pressure. 20 PSI is a long way from 150 PSI.

I've tried this thing with and without the check valve installed already. Same issue.

Here’s some pictures of my check valve.

This is the bottom(tank end) of the valve.

View attachment 16861

Here I’m holding the valve open with a nail. You can see the bleed hole on the flat of the hex.

View attachment 16860

And here is a #72 drill in the bleed port.

View attachment 16859

Yup that's what this new check valve looks like alright. The bleed hole might be a little smaller though.

Maybe It’s the lack of a flywheel?

That's what I'm starting to think. Do you know if the head you have is functional?

Last edited:

Johnwa

Ultra Member

It worked well enough to determine the tank on it leaked. I actually picked it up just for the tank which is now my aluminum melting furnace.That's what I'm starting to think. Do know if the head you have is functional?

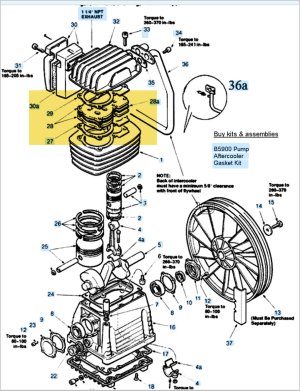

I don't know these units very well but (generically) isn't there a valve assembly in the head? If those were faulty, would that exhibit some of these issues? For example it max's at say 25 psi then. In your open air discharge test the check valve pops opens OK, but the compressor only sees 14 psi atmospheric forever so continues to run (25>14). But when flowed back to tank, pressure increases until the maximum 25 psi is reached & then dies.

Attachments

I don't know these units very well but (generically) isn't there a valve assembly in the head? If those were faulty, would that exhibit some of these issues?

There are reed valves in the head that open to allow intake air into the cylinders during the down stroke. As far as I know if they fail you will never achieve pressure during the compression stroke. These things appear to be dead simple in theory????

I agree. Lack of seal might explain low pressure never building up and has to bypass somewhere. But (if I understand) your over-amping despite different motors is pointing to an excess load issue. I'd pop the head for a looksee & eliminate some more variables. Keep Googling, someone must have experiences something similar.

You won't believe what actually worked... sort of.

The original 10" pulley and Poly-V Belt.

Got up to 100 psi and then the belt started slipping on the motor pulley. At no time did the motor stall or trip the 20 amp breaker. Can't blame the belt for slipping I was running it with a standard V-Belt pulley. Who would have thought you could get away with that. I don't think that belt is going to let me try that experiment again. That said, I'm convinced one cylinder is not functioning. Took a good 1/2 hour to attain 100 psi. At about 80 psi I couldn't perceive any reed valve flutter on one cylinder and the whole thing was shaking pretty good. As in walk out of the shed shaking.

The original 10" pulley and Poly-V Belt.

Got up to 100 psi and then the belt started slipping on the motor pulley. At no time did the motor stall or trip the 20 amp breaker. Can't blame the belt for slipping I was running it with a standard V-Belt pulley. Who would have thought you could get away with that. I don't think that belt is going to let me try that experiment again. That said, I'm convinced one cylinder is not functioning. Took a good 1/2 hour to attain 100 psi. At about 80 psi I couldn't perceive any reed valve flutter on one cylinder and the whole thing was shaking pretty good. As in walk out of the shed shaking.

Last edited:

The saga continues....

Last night I made this flat pulley to try on the motor.

I got to 110 psi and the breaker tripped. Gave it another go and got to 120 psi and the breaker tripped. That belt isn't slipping any more. Gave in another go and she just wasn't going to do any better.

A few hours latter, I decided to see if she would do it again. I blew the tank down to 0 psi and started it up. WTF the breaker trips at 10 psi, and then again at 20 psi and finally the motor circuit protection breaker tripped at 110 psi I dunno....

I dunno....

Last night I made this flat pulley to try on the motor.

I got to 110 psi and the breaker tripped. Gave it another go and got to 120 psi and the breaker tripped. That belt isn't slipping any more. Gave in another go and she just wasn't going to do any better.

A few hours latter, I decided to see if she would do it again. I blew the tank down to 0 psi and started it up. WTF the breaker trips at 10 psi, and then again at 20 psi and finally the motor circuit protection breaker tripped at 110 psi

Last edited:

What size breaker are you using it sounds like maybe go up one.

It's a 20 amp circuit and a cheap 50' extension cord. I tried running it without the extension cord and it didn't appear to make any difference. It tripped the breaker again at 120 psi. The strange thing is... when the breaker trips the head is easy enough to pull through by hand?

Last edited:

Do you have a picture of the motor data plate?

How far is the 20A plug from the breaker panel?

What size wire is between the 20A panel breaker and the plug?

A 2hp motor on 120V is pushing a 20A circuit - especially on a compressor.

It's a 20 amp breaker wired with approx 4' of 12 gauge wire to the plug. The motor plate states 22 Max amps for 120V.

Looks like the circuit is correct for 20A, 120V.

I think the breaker is tripping because of the internal thermal protection since you have to run the motor for some time.

You have a way to measure the current?

Any way you can connect to a 240V circuit (change the wiring in the motor to correspond) to see if that would work?

I think the breaker is tripping because of the internal thermal protection since you have to run the motor for some time.

You have a way to measure the current?

Any way you can connect to a 240V circuit (change the wiring in the motor to correspond) to see if that would work?

Looks like the circuit is correct for 20A, 120V.

I think the breaker is tripping because of the internal thermal protection since you have to run the motor for some time.

You have a way to measure the current?

Any way you can connect to a 240V circuit (change the wiring in the motor to correspond) to see if that would work?

Don't have access to a 240V circuit to try and not interested in installing one just to run this thing in my garden shed. The original motor on this would have been 240V for sure. What perplexes me is why this thing loads up in such an inconsistent manner 10 PSI, 20 PSI, 110 PSI, 120 PSI etc. @Johnwa has what looked to me to be the same compressor head running with a 1hp 120V motor? Tank size should only affect fill time correct?