And real cool jazz music too!! I want one!

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool 6” GS / Gerardi Modular Vise Clone

- Thread starter RobinHood

- Start date

Tool

Well, they do make the vises in different sizes… so maybe there is one that fits your needs?I want one!

Fyi - (in my post #9 above) - i found that video because i was looking for information so that i could understand how a modular vise worked. This has all been quite interesting. The videos you linked above (post #20) are excellent explanations of this type of vise. Thanks.

Just disassembled the whole vise. It is full of grinding dust mixed with the preservative oil!

It measures 88.436mm across the whole width. That is good.

Yes, identical gap, just on the opposite side - the block was installed out of square. There is just enough play in the key way to take out the deviation. I will do that at reassembly. That is good news!

Out of curiosity, can you mic the fixed jaw width on both sides to see how close they are?

Also when you saw the light gap squareness check (red) was that replicated on the other side of fixed jaw block (yellow)

It measures 88.436mm across the whole width. That is good.

Yes, identical gap, just on the opposite side - the block was installed out of square. There is just enough play in the key way to take out the deviation. I will do that at reassembly. That is good news!

Yes, for the $s, it was.I am (and I’m sure others are too) anxiously awaiting your verdict:

- Was it a good buy?

- Would you recommend this Chinese clone?

- Would you keep it even if they offered a 100% refund of all your costs including return shipping?

Yes, with the provision that it does not have all the functionalities of a real Gerardi. I’ll elaborate later…

Yes, I am going to keep it. It will be fully functional once I get done with it.

Here is a factory video from Gerardi.

I just spent 2 hours looking for instructions. I ended up emailing both Gerardi and Sowa. Then you throw this out there! LOL!

I'm sure I'll have more comments later.

I watched the video, ya nice jazz. Better than listening to my wife's cousin in Italy.

On the down side, no details on disassembly, adjustment, reassembly, applications, etc etc.

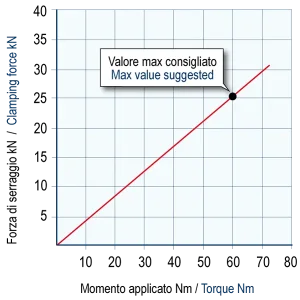

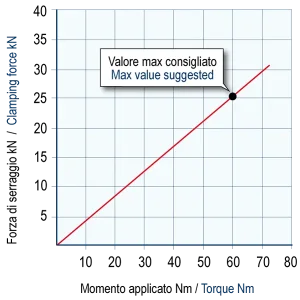

On the Gerardi website, I did find this chart for drawdown force vs screw torque. There is a graph for each type. Mine is a type 2.

I'll provide any info later when I hear back from Gerardi and Sowa.

On the down side, no details on disassembly, adjustment, reassembly, applications, etc etc.

On the Gerardi website, I did find this chart for drawdown force vs screw torque. There is a graph for each type. Mine is a type 2.

I'll provide any info later when I hear back from Gerardi and Sowa.

I’ll elaborate later…

If you check out the Gerardi factory video I posted in #20 above, they have “accessory” jaws and even jaw blocks. At about the 2min mark they start showing them.

One of the special ones is the movable jaw block with the Vs in it which allows for round objects to be held vertically in three different positions. That jaw block also has the complimentary “grip groove” at the top which matches the groove on the fixed jaw block when you turn it around.

Gerardi also offers jaw blocks that can take conventional, rectangular jaws which don’t pull down.

They also show a movable jaw to hold irregular objects.

Now, if my Clone is an exact copy of the base model of the Gerardi, these accessories may fit it, if I chose to go that route. It might cost me an arm and a leg to get them as well. So pretty big gamble…

That’s why I said the Clone is no Gerardi.

Last edited:

Overall, great.Came here after the hairy guy informed me of your purchase

How did this saga work out ?

Thanks

It was a learning curve for me w.r.t. using it properly. Once I had that figured out, I like it a lot.

I do need to come up with a way to protect all the nooks and crannies from chips. The critical components are more exposed than on a Kurt style vise…

Please refer to my post #25 above for the details. Cole’s notes: yes, I was able to install it square to the base.What was the final result of the jaw squareness?

For the prismatic jaw modular vise I bought, there are two basic modes of operation: “floating jaw“ & “fixed jaw”. In floating jaw mode, each jaw pulls down as you tighten the vise because of the shape of the back side of each jaw plate. In fixed jaw mode, it acts like your standard bench vise.

I suggest you watch the video from Gerardi below. They explain the operation much better than I can. They also go into what other components are available for their modular vise.

Standard Vises - Gerardi SPA

The most popular (and copied) vise in the world - The perfect mix: price, quality, versatility.

And here is another video showing the pull down action.

Last edited:

I just went out to the mill and took a couple of pics of my Gerardi.

The quality of the vise plus the logo on top and the stamped ‘Gerardi’ on the side confirmed that my Kijiji find was authentic.

As @Susquatch and @RobinHood explained above - the big benefit of this vise is the floating jaws that clamp downward on the part as the jaws are tightened. No longer need to tap down on the part to get the parallels tight. In pics below, I tighten the part and then pushed laterally on the parallels as much as I could with my thumb. This is the main reason i think this vise design is awesome and well worth the price of admission.

They are called modular vises because the height of the base is an exact dimension for each particular model. Therefore if you have several vises you can clamp a long part down onto the base of several vises and the part will be perfectly parallel to the mill table.

FYI- Here’s another previous post about my vise:

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

The quality of the vise plus the logo on top and the stamped ‘Gerardi’ on the side confirmed that my Kijiji find was authentic.

As @Susquatch and @RobinHood explained above - the big benefit of this vise is the floating jaws that clamp downward on the part as the jaws are tightened. No longer need to tap down on the part to get the parallels tight. In pics below, I tighten the part and then pushed laterally on the parallels as much as I could with my thumb. This is the main reason i think this vise design is awesome and well worth the price of admission.

They are called modular vises because the height of the base is an exact dimension for each particular model. Therefore if you have several vises you can clamp a long part down onto the base of several vises and the part will be perfectly parallel to the mill table.

FYI- Here’s another previous post about my vise:

IT'S TOO BIGGGGG!

You know, I had (have) a small 2" vise on my mini mill. Great for small things obviously but not so much for anything big or for making aggressive cuts. So I thought it was time to get something bigger, better, more accurate, more cool looking. Well, apparently a 4" CNC vise is almost as big as...

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

PS - because the benefits of this vise are not well know - I plan to bring it to April 6 meetup in Markham

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

Ontario meetup, April 6

I am hoping to attend. Work travel may interfere but I’m trying to keep the day clear.

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

Proxule

Ultra Member

Please refer to my post #25 above for the details. Cole’s notes: yes, I was able to install it square to the base.

For the prismatic jaw modular vise I bought, there are two basic modes of operation: “floating jaw“ & “fixed jaw”. In floating jaw mode, each jaw pulls down as you tighten the vise because of the shape of the back side of each jaw plate. In fixed jaw mode, it acts like your standard bench vise.

I suggest you watch the video from Gerardi below. They explain the operation much better than I can. They also go into what other components are available for their modular vise.

Standard Vises - Gerardi SPA

The most popular (and copied) vise in the world - The perfect mix: price, quality, versatility.www.gerardispa.com

And here is another video showing the pull down action.

Guess what? The fixed jaw on my vise is also not square to the bed! It is off by about 0.004” over 6”. Does it really matter? I don’t think so, as the fixed jaw gets used to tram the vise to the mill‘s Y-axis and any error gets removed that way. Does it bug me? Yes & No. No, because of what I just said before; Yes, because all other dimensions on this vise are right on the money!

Much appreciated on the info and links, I have watched the videos. Impressive vise. I understand how it works now, Is there any reason to have the jaws fixed vs. pulling down as you tighten it. As in a pro vs. con - one vs. the other?

I also took note how it was trammed, you must clamp down on a parallel or similar and tram it in.

I will give it some serious thought,

The 5 inch vise comes in at 435$ and free shipping. I think that would be a suitable size for a RF45 mill.

( There is a big sale coming up )

Do you remember what the cost was on the 5" when you bought?

You mention the fixed jaw is not square, and that tramming removes that error. Do you mean that its not square to the base of the vise or when you flip it on its side its not square to the bed, And when you flip it the proper way, you tram the fixed jaw to remove the error?

A little unclear to me - I am not the sharpest knife in the drawer, lol

Thanks

Is there any reason to have the jaws fixed vs. pulling down as you tighten it. As in a pro vs. con - one vs. the other?

I've never used my Genuine Gerardi in any mode other than prismatic (moving jaws). I really can't imagine a time when I'd want to use it with the Jaws tightened down. But it's there if that time ever came.

Anyone out there know of a time when that might be needed?

Prismatic mode is amazing. I put my hammer away. Not needed anymore.

I trammed my table, then trammed the vise. I trammed the vise with a parallel clamped in the Prismatic jaws, and a dial test indicator mounted in the spindle.

Important to clean and oil the vise periodically.

Note - I have never I owned a Kurt. However I have a similar Grizzly that I used on my mill drill. I had planned to use it on whatever bigger mill I ended up getting.

However when I got my Hartford BPort Clone, it came with the Gerardi. My plan on arrival was to sell the Girard and install the Grizzly. That plan changed as I used the Girard and learned more about it.

Today, I would buy a Girardi clone before a Kurt.

Last edited:

Or, use the jaw plate lock-down screws pull them all the way down onto their bed reference surfaces and just tram as usual (green arrows).I also took note how it was trammed, you must clamp down on a parallel or similar and tram it in.

That seem about correct. I did not specifically note the price, though.The 5 inch vise comes in at 435$ and free shipping. I think that would be a suitable size for a RF45 mill.

( There is a big sale coming up )

Do you remember what the cost was on the 5" when you bought?

The fixed jaw block WAS not square to the base because of debris in the jaw block-to-bed keyway (red arrow). After cleaning and reassembly, I was able to install the fixed jaw block square to the base.You mention the fixed jaw is not square, and that tramming removes that error. Do you mean that its not square to the base of the vise or when you flip it on its side its not square to the bed, And when you flip it the proper way, you tram the fixed jaw to remove the error?

IF you are using the vise in the prismatic pull-down mode, it is absolutely crucial that there is no debris between the jaw plates and their reference surface (both the angled back face and the bottom). Otherwise the jaw plate “hangs up” and thus the clamping geometry will be off.

Proxule

Ultra Member

Fantatic reply, answered all my questions. Much appreciatedOr, use the jaw plate lock-down screws pull them all the way down onto their bed reference surfaces and just tram as usual (green arrows).

View attachment 45615

That seem about correct. I did not specifically note the price, though.

The fixed jaw block WAS not square to the base because of debris in the jaw block-to-bed keyway (red arrow). After cleaning and reassembly, I was able to install the fixed jaw block square to the base.

View attachment 45614

IF you are using the vise in the prismatic pull-down mode, it is absolutely crucial that there is no debris between the jaw plates and their reference surface (both the angled back face and the bottom). Otherwise the jaw plate “hangs up” and thus the clamping geometry will be off.

I now commence the sweet talk with the wife. Lol