What is a “Precision Bench Vise Work Bench 4/5/6Inch Clamp Machine” you ask? Well, it is a GS / Gerardi Modular Vise clone made in China.

Something was lost in translation somewhere…

A 6” new Gerardi branded one is in the $1800+tax & S+H range; a GS or SOWA branded one is still $1200+tax & S+H.

So I decided to give one of the clones a try.

Ordered it on 13/Dec/2023 from Shanghai, CN, and the UPS man just delivered it this afternoon.

Selected the UPS Expedited shipping method (it was Free on 13/Dec/2023 - not any more; now it seems an additional $26 or so).

On 17/Dec/2023 I was notified by UPS that the package had cleared customs here in Calgary (it actually arrived on 15/Dec/2023 in YYC!) and I had to pay $42.97 [duty ($17.27), GST ($14.15) brokerage fee ($11.55 incl. GST)].

I suspected there were taxes + fees due when I ordered the vise. So was not surprised. Total cost delivered to my door: $634.50.

The vise weighs 30kg (~66lbs) plus the accessories (4 hold down clamps, vise stop, the main handle, plus the little T-handled hex key for the movable jaw adjustment).

It was double boxed: inner box with vise & acc, then an outer shipping box with foam padding all the way around. Everything was plastic strapped together.

The vise itself was inside a heavy plastic bag with lots of rust inhibiting oil all over the surfaces.

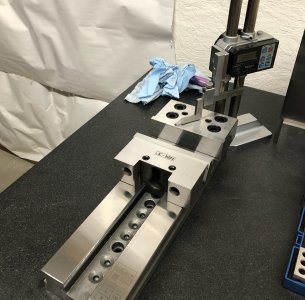

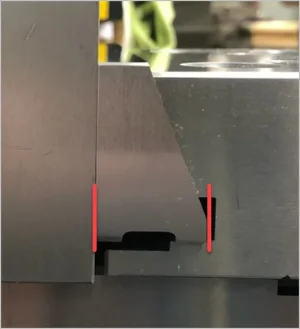

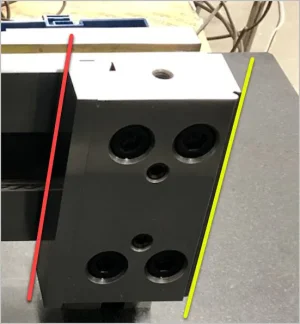

First impression of the vise is very good. No nicks, dings, scratches, etc. Everything looks straight & moves freely as it should. Only “fault“ so far was the accessory cardboard box was torn open - I suspect that was because of all the preservative oil had soaked the glue joints and it just fell apart.

I plan on a complete disassembly, clean, inspection and reassembly in the very near future.

I’ll report my findings here…

Disclaimer: I am in no way affiliated, sponsored or have any commercial interest in this company/item. I am just an AliExpress customer.

Something was lost in translation somewhere…

A 6” new Gerardi branded one is in the $1800+tax & S+H range; a GS or SOWA branded one is still $1200+tax & S+H.

So I decided to give one of the clones a try.

Ordered it on 13/Dec/2023 from Shanghai, CN, and the UPS man just delivered it this afternoon.

Selected the UPS Expedited shipping method (it was Free on 13/Dec/2023 - not any more; now it seems an additional $26 or so).

On 17/Dec/2023 I was notified by UPS that the package had cleared customs here in Calgary (it actually arrived on 15/Dec/2023 in YYC!) and I had to pay $42.97 [duty ($17.27), GST ($14.15) brokerage fee ($11.55 incl. GST)].

I suspected there were taxes + fees due when I ordered the vise. So was not surprised. Total cost delivered to my door: $634.50.

The vise weighs 30kg (~66lbs) plus the accessories (4 hold down clamps, vise stop, the main handle, plus the little T-handled hex key for the movable jaw adjustment).

It was double boxed: inner box with vise & acc, then an outer shipping box with foam padding all the way around. Everything was plastic strapped together.

The vise itself was inside a heavy plastic bag with lots of rust inhibiting oil all over the surfaces.

First impression of the vise is very good. No nicks, dings, scratches, etc. Everything looks straight & moves freely as it should. Only “fault“ so far was the accessory cardboard box was torn open - I suspect that was because of all the preservative oil had soaked the glue joints and it just fell apart.

I plan on a complete disassembly, clean, inspection and reassembly in the very near future.

I’ll report my findings here…

Disclaimer: I am in no way affiliated, sponsored or have any commercial interest in this company/item. I am just an AliExpress customer.

Last edited: