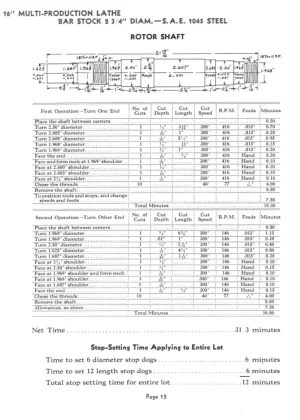

I was surfing Vintage Machinery website, Keith Rucker, and he has tons of machinery manuals. I looked at the American Pacemaker, which is supposed to be a top notch lathe. What astounded me more than anything else, was that in the last several pages of the manual, it gives examples of work that can be performed on the lathe, including specific procedures, speeds, feeds, and times. Have a look. On the Rotor Shaft, it state that it should take a net time of 31 minutes. Man, it would take me the whole day to do that!

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WOW, Speed of Machining

- Thread starter thestelster

- Start date

You know, thinking about this, can any new machinists be able to produce this shaft this quickly, (with or without a DRO!!) Have we become so soft in our teaching discipline to only accept mediocrity. The cost of labour increasing, and the speed of production decreasing, we have to either farm out to 3rd world countries, where labour is cheap, or tool up to CNC's and robotics or 3D Printing. Is this sustainable in the long run?Likewise, a whole day... EASY!

But I suppose that's the difference between seasoned and hobbyist ? !

Last edited:

This lathe is a very rigid “production lathe” with some added features “normal lathes” don’t have. Notice on the bottom of the reference page: “setting diameter and length stop dogs: 12 min.” Most lathes do not have these features.

Once the machine is set-up, the part can be made in 31 min. Not before. Also, the stock comes pre-cut and with centers already in.

Yes, and some heavy cuts…

Once the machine is set-up, the part can be made in 31 min. Not before. Also, the stock comes pre-cut and with centers already in.

Yes, and some heavy cuts…

On the Rotor Shaft, it state that it should take a net time of 31 minutes. Man, it would take me the whole day to do that!

I dunno.

On the time sheet, it says "chase threads" for 4 minutes each with 10 passes of 18tpi 11/16" length at 77 rpm. And no time to change bits or take measurements. At 10 passes in 4 minutes, that's a pass every 30 seconds. The lathe alone will take 11/16 x 18 = 12 revolutions to cut each pass. At 77 rpm, thats about 10 seconds just for cutting with no lead-in or waiting for the thread dial or disengaging the half nut, or cranking out the tool, or backing off for another pass or taking any measurements.

I do most of my threading at 70 rpm. For most lathes 18tpi is an even number thread that can only be cut on two locations on the thread dial at opposite extremes (say marks 1 & 3 or 2 & 4). It takes up to 20 seconds to transition to one of those numbers which is an average of 10 seconds depending on how lucky you are. It's impossible to get 0 unless the lathe is stopped or you deliberately crank the carriage back to hit zero which means you have extra empty space to thread at the beginning of each pass.

In other words, in an ideal world, it takes 20 seconds to cut per pass. Leaving only 10 seconds to disengage, retract, rewind, take a measurement, dial in the next pass, and engage the half nut.

Is it possible? Ya, it's possible. So it survived the sniff test. But it requires robotic precision that only CNC can do. Mere mortal human beings can only dream of doing that.

You know what I'd love to see?....A tv series, "Canada's Best Machinist".

Machinists compete head to head to make a part in the quickest time, to spec, and rated on finish quality. Contestants use the same lathe, milling machine, surface grinder, or whatever. Same qualified measuring tools, same cutters. Can you imagine?! Blue chips flying, the sparks, the noise?

Machinists compete head to head to make a part in the quickest time, to spec, and rated on finish quality. Contestants use the same lathe, milling machine, surface grinder, or whatever. Same qualified measuring tools, same cutters. Can you imagine?! Blue chips flying, the sparks, the noise?

Last edited:

Matt-Aburg

Ultra Member

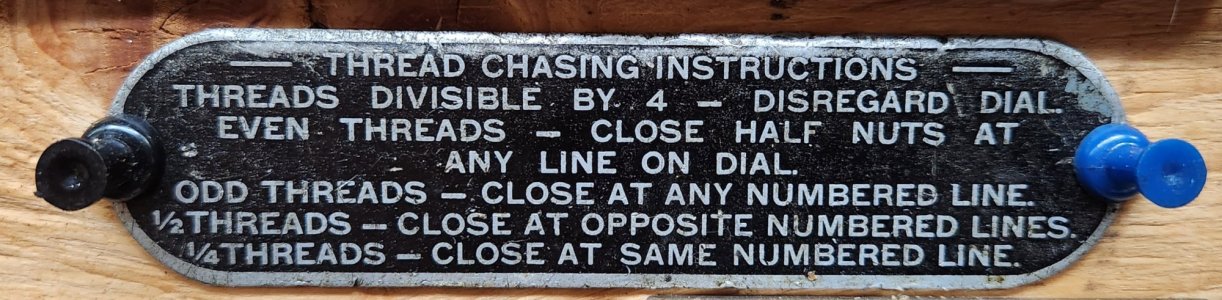

I leave it engaged and reverse. Don't have to worry about dial... (one time only)... Other than that, they do not count human factor...I dunno.

On the time sheet, it says "chase threads" for 4 minutes each with 10 passes of 18tpi 11/16" length at 77 rpm. And no time to change bits or take measurements. At 10 passes in 4 minutes, that's a pass every 30 seconds. The lathe alone will take 11/16 x 18 = 12 revolutions to cut each pass. At 77 rpm, thats about 10 seconds just for cutting with no lead-in or waiting for the thread dial or disengaging the half nut, or cranking out the tool, or backing off for another pass or taking any measurements.

I do most of my threading at 70 rpm. For most lathes 18tpi is an even number thread that can only be cut on two locations on the thread dial at opposite extremes (say marks 1 & 3 or 2 & 4). It takes up to 20 seconds to transition to one of those numbers which is an average of 10 seconds depending on how lucky you are. It's impossible to get 0 unless the lathe is stopped or you deliberately crank the carriage back to hit zero which means you have extra empty space to thread at the beginning of each pass.

In other words, in an ideal world, it takes 20 seconds to cut per pass. Leaving only 10 seconds to disengage, retract, rewind, take a measurement, dial in the next pass, and engage the half nut.

Is it possible? Ya, it's possible. So it survived the sniff test. But it requires robotic precision that only CNC can do. Mere mortal human beings can only dream of doing that.

On my lathe, even numbered threads are cut on any line one the dial.I do most of my threading at 70 rpm. For most lathes 18tpi is an even number thread that can only be cut on two locations on the thread dial at opposite extremes (say marks 1 & 3 or 2 & 4). It takes up to 20 seconds to transition to one of those numbers which is an average of 10 seconds depending on how lucky you are. It's impossible to get 0 unless the lathe is stopped or you deliberately crank the carriage back to hit zero which means you have extra empty space to thread at the beginning of each pass.

Attachments

TorontoBuilder

Ultra Member

dont say another word or someone will steal your idea.You know what I'd love to see?....A tv series, "Canada's Best Machinist".

Machinists compete head to head to make a part in the quickest time, to spec, and rated on finish quality. Contests use the same lathe, milling machine, surface grinder, or whatever. Same qualified measuring tools, same cutters. Can you imagine?! Blue chips flying, the sparks, the noise?

this is a very doable show, with a market

Please, please, someone, steal my idea. Much better than watching a baking show!dont say another word or someone will steal your idea.

this is a very doable show, with a market

Well if we are grabbing ideas I'll claim "Canada's worst machinist" I have quite the resume and am well prepared to compete in that one!!

You know....back when I use to shoot pistol competitively, we use to have what was called Postal Matches. Instead of traveling all over Canada to compete in person, you would shoot the course at your gun club, and report the scores. Certain rules applied, and it was based on the honour system. We could do the same thing here.

A set of blue prints get sent to registrants, and you have 3 hours to produce the part. You time yourself, and add time or demerit points for every aspect not to spec. Divide the contestants into categories depending on their experience. Bonus points to guys with smaller machines, or no DRO's, or whatever. Everybody ante's up $10.00 or whatever, and proceeds get divided to top 2 or 3 per division.

End of the year, banquet and awards. How fun would that be?

A set of blue prints get sent to registrants, and you have 3 hours to produce the part. You time yourself, and add time or demerit points for every aspect not to spec. Divide the contestants into categories depending on their experience. Bonus points to guys with smaller machines, or no DRO's, or whatever. Everybody ante's up $10.00 or whatever, and proceeds get divided to top 2 or 3 per division.

End of the year, banquet and awards. How fun would that be?

Fixed this for folks like me...

A set of blue prints get sent to registrants, and you have 3hours days to produce the part. You time yourself, and add time or demerit points for every aspect not to spec. Divide the contestants into categories depending on their experience. Bonus points to guys with smaller machines, or no DRO's, or whatever. Everybody ante's up $10.00 or whatever, and proceeds get divided to top 2 or 3 per division.

A set of blue prints get sent to registrants, and you have 3

If you leave it engaged and reverse, your 10 seconds are gone cuz you have to reverse at the same speed as forward.I leave it engaged and reverse. Don't have to worry about dial... (one time only)... Other than that, they do not count human factor...

If you crank backward, you can go faster.

On my lathe, even numbered threads are cut on any line one the dial.

Ya, I know that every lathe has different thread dial constraints. I only used mine as an example.

I was really only making the point that normal humans can't do what they claim.

It's marketing BS.

Fundamentally, I'm like you. That job would take me a day. Maybe two.

Well, for only $4K one can test the machining speed on a recent model of the American lathe:

American Lathe Model 729 - heavy equipment - by owner

Specifications: 600 V 60 A 3 Phase DRO on unit Three Extra Chucks 6 foot bed 1.25″ bore diameter Selling well below value because we want it gone. Buyer must arrange and pay for shipping (crane...

vancouver.craigslist.org

I think I will give this a test run, or at least just the thread, when I have an opportunity. I'm sure I can do it within the allotted time of 4 minutes. For the other segments, since I don't have multiple stops, I'll wait until I get the DRO.I dunno.

On the time sheet, it says "chase threads" for 4 minutes each with 10 passes of 18tpi 11/16" length at 77 rpm. And no time to change bits or take measurements. At 10 passes in 4 minutes, that's a pass every 30 seconds. The lathe alone will take 11/16 x 18 = 12 revolutions to cut each pass. At 77 rpm, thats about 10 seconds just for cutting with no lead-in or waiting for the thread dial or disengaging the half nut, or cranking out the tool, or backing off for another pass or taking any measurements.

I do most of my threading at 70 rpm. For most lathes 18tpi is an even number thread that can only be cut on two locations on the thread dial at opposite extremes (say marks 1 & 3 or 2 & 4). It takes up to 20 seconds to transition to one of those numbers which is an average of 10 seconds depending on how lucky you are. It's impossible to get 0 unless the lathe is stopped or you deliberately crank the carriage back to hit zero which means you have extra empty space to thread at the beginning of each pass.

In other words, in an ideal world, it takes 20 seconds to cut per pass. Leaving only 10 seconds to disengage, retract, rewind, take a measurement, dial in the next pass, and engage the half nut.

Is it possible? Ya, it's possible. So it survived the sniff test. But it requires robotic precision that only CNC can do. Mere mortal human beings can only dream of doing that.

I think I will give this a test run, or at least just the thread, when I have an opportunity. I'm sure I can do it within the allotted time of 4 minutes. For the other segments, since I don't have multiple stops, I'll wait until I get the DRO.

If you can do that all in under 4 minutes, I'm, going to recommend a new class if membership - "THOSE WHO WALK ON WATER". Don't forget that setup and measurements must be included in the time.....

Your word that you did it will be all that I need to pursue the new membership category.