Ive run 4 LPG vehicles in my life.

In the early 80's I met a gentleman in Penticton, Vic Starret, him and his buddies started a company called OHG (which stood for over the hill gang)

They designed and manufactured the first Lpg equipment in canada in the late 50's, which was first used in field pumps in the oil industry long before used on the road. They invented the converter.

The first vehicle was a GMC 2500 I pulled out the 350 V8 and put in a 300 6 cyl, I did the complete conversion myself then got an inspection and the sticker. I think lpg went up to around 25 cents a litre at that time. I was 18?

The second, I got a used1979 E 250 ford cargo van, existing lpg system. Around 280,000? km when I got it. That was about 1987

Propane was 18 or 19 cents a litre, just over half the price of gasoline.

3rd, in 1997, a 1990 F350 1t dually with a 95 l tank between the frame rails behind the axle. I built a custom flat deck on that. Came with the conversion but i had to pull out the tank, it was very pitted under the mounting straps. Sand blast and prime the tank make new mounting straps and put it back. I was always nervous about the rust pitting but it never ruptured

4th (2005) was a 1980 F250, pulled off the box did some rust repairs, burgundy paint, mounted air bags and put on a welding deck with a new miller 300D . That had a fitting in the tank for the cutting torch. Put a big size oxy tank.

Again, did the conversion myself.

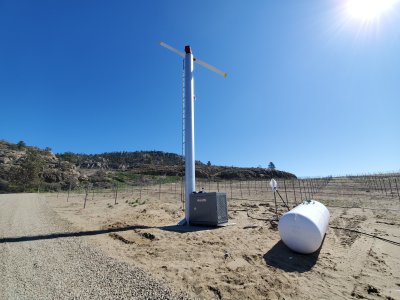

At that time I got a 1000 L tank with a dispenser from a co. called Autogas.

I got wholesale pricing i think that was around .45/l.

I was filling the welding truck, the 1ton, ran 3 sets of cutting torches, a 12 burner forge, heated both my buildings, filled everyones BBQ tanks and even cooked my oatmeal in the morning on the lpg converted kitchen stove. We filled the trucks at the end of the day and never ever had to stop and waste time at a gas station. We had total efficiency and huge savings.

In 2010 I closed the welding business after 18 yrs, sold the trucks. Propane was getting much more expensive, conversions were costly so that was the end of the run.

When I had the dispenser, the tank was hooked up for building heating, I had wholesale pricing and the BEST PART OF ALL.... I paid ZERO road tax for over 10 yrs! kinda hard for them to check for purple propane! Lol

Vic told me propane has a higher octane than gasoline. The colder the air the better...have some kind of duct from the grill to the air cleaner to force the air. Injection is definitely the way to go now. LPG burns without carbon I could go 20k between oil changes cause it never got dirty.

A long time ago I did some rough calculations and I figured I'd saved oh... around $85,000 in vehicle fuel costs. And that was 5 yrs or so before i stopped using it.

Some said ."Oh, but you get less performance on LPG!

I didn give a dry rats anus about that.

When I was pulling up a hill with 3000# and my lpg 460 under the hood I had all the power I needed.

I just laughed at those guys.

Sorry about the long winded story.

It was good to try to remember all of that.

Best to you all.

R