-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

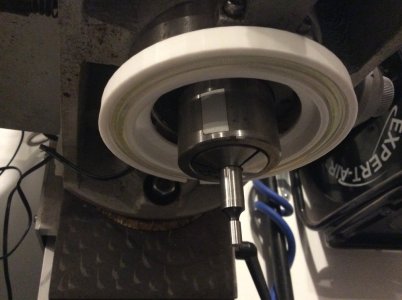

What are you using for spindle lighting?

- Thread starter thriller007

- Start date

That looks great. I've seen them made & sold by others. For sure its the most direct, localized light source orientation. I even bought an offshore strip LED kit & made some drawings for a fixture, its been sitting there since my old mill was around. One thing that gave me pause is I mount my indicator clamp on the same area. Not that I use it a ton but when I need it I need it. So it was enough to make me pause. I'm hoping my ceiling LED retrofit will come to the rescue (one day!). The lighting company I dealt with said no issues stringing more fixtures together so that's what I'l counting on (one day!).

Last edited:

thriller007

Well-Known Member

https://www.amazon.ca/Angle-100mm-A...+led+ring+drl+halo+ring&qid=1610212202&sr=8-1Is that an automotive light?

I went with the 100 mm and designed around that.

Wow, already in ring form. I wasn't even aware they made those.

I bought a linear strip (years ago). You can snip the strip every so often minimum number of LEDs & so hook up in different kinds of arrays. I've seen people make their own light fixture box panels like this. But much more work that what you did there with the ring. Good execution.

I bought a linear strip (years ago). You can snip the strip every so often minimum number of LEDs & so hook up in different kinds of arrays. I've seen people make their own light fixture box panels like this. But much more work that what you did there with the ring. Good execution.

thriller007

Well-Known Member

yes I did. And started by measuring how much room I had and what size the light was to design around. As it worked out it was a bit tight. If I was to do it again I would increase the OD by about a 1/2 mm. It went in tight enough that no glue was needed. Also if I was to do it again I would print in a darker color so it did not look like a halo from the outside. Now I need to make one for my drill press.Did you just get a 12V wall wart for power?

Attachments

thriller007

Well-Known Member

This one is just magnetic mounted so you can just pull it off if you need to do so.That looks great. I've seen them made & sold by others. For sure its the most direct, localized light source orientation. I even bought an offshore strip LED kit & made some drawings for a fixture, its been sitting there since my old mill was around. One thing that gave me pause is I mount my indicator clamp on the same area. Not that I use it a ton but when I need it I need it. So it was enough to make me pause. I'm hoping my ceiling LED retrofit will come to the rescue (one day!). The lighting company I dealt with said no issues stringing more fixtures together so that's what I'l counting on (one day!).