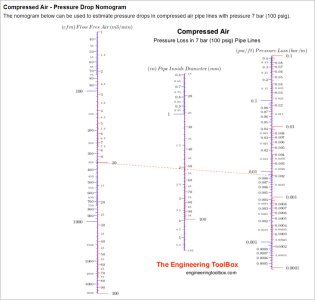

Its been a while since I looked at this stuff, but I think pressure drop in fittings is a bit different again. If I remember correctly, some equate the fitting (ID, type of bend, passage length...) to X length of pipe equivalent so you can refer to same pipe charts & estimate their drop contribution. Then there are orifice calculators that have D/d & other parameters?

I also recall regulators may have their own criteria in terms of flow rate, delta-P limit or relative-P. Best to check the specs. I know this is a big deal with CO2 if freeze off conditions occur (not related to water content, its a phase diagram thing). But I don't think this pertains to N2. I heard of guys doing airbrushing with N2, maybe this is why. No noise!

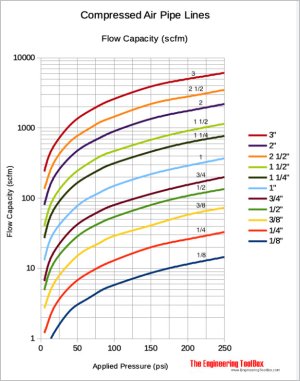

Fittings in compressed air pipe lines and equivalent length pressure drop.

www.engineeringtoolbox.com