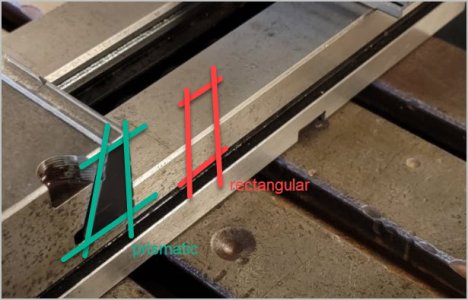

I guess mill down the 5/8 parts to fit the groove.

I suppose That would certainly work.

Just goes against my grain to modify a universal tool like that. Then again, the clamp pieces are sold separately and are quite inexpensive.

It would certainly get me going quickly and then I could make proper Clamps later.