I think I followed that @PeterT.

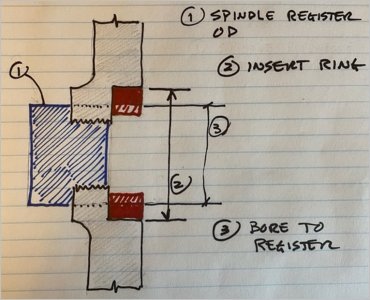

Is it possible that @SparWeb's original unfinished backplate was never intended to cut threads any longer than they are now but rather that the original intent was to bore the register ID from the other side next, but they could not figure out how to locate it properly so they abandoned the project?

Edit - I find it a bit hard to believe that anyone would make a threading tool that wasn't long enough to finish the job. So I think it was intentionally short for tool rigidity.

Is it possible that @SparWeb's original unfinished backplate was never intended to cut threads any longer than they are now but rather that the original intent was to bore the register ID from the other side next, but they could not figure out how to locate it properly so they abandoned the project?

Edit - I find it a bit hard to believe that anyone would make a threading tool that wasn't long enough to finish the job. So I think it was intentionally short for tool rigidity.

Last edited: