File is a plain txt file, I couldn't upload as an .ino file.

No snickering or snide comments about my coding is allowed, I'll start to cry. I'd be happy to have a better programmer clean up this code, hint hint...

And no whining about my using two pots to select cutter diameter and material, it's cheap, simple to code, and means each dial only has one function, a defining characteristic of good HMI design. I could have changed it to a rotary encoder, but Arduino nanos only have two interrupt pins, so it would need a menu system and multiple steps to select inputs, so why bother?

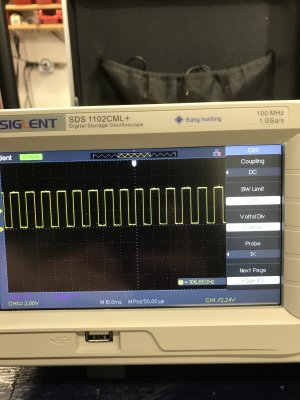

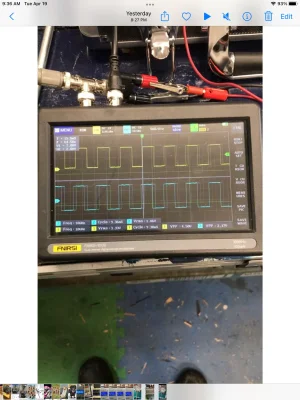

My mill has a 16-hole disc on the quill, just change the RPM Array formula to match the number of pulses available per revolution. And any IR sensor will work, I first set it up with a reflective sensor and a single chunk of white tape on the quill.

My mill tops out a 2000 RPM, so my <cal rpm> function displays ">2000" for any calculated rpm values above 2000, no point in displaying something my mill can't do. YMMV

There is no code restrictions on the actual tachometer display, I've successfully tested this at 5,000 RPM with good results.

/*

Modified from:

Author: Chris @ PyroElectro.com

Date: 8/26/2012

Description:

This project is meant to capture interrupt counts from an IR breakbeam circuit

and display them as an RPM number on a 16x2 LCD module.

Full Project Details:

http://www.pyroelectro.com/tutorials/tachometer_rpm_arduino/

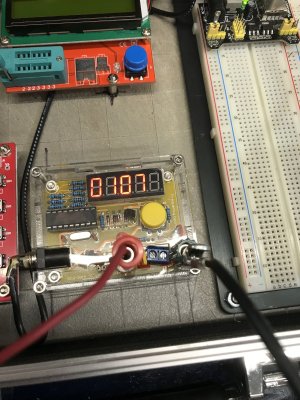

components

Arduino Nano

Nano screw terminal board

20x4 LCD with I2C interface

Two 10K pots

LM393 slot-type iR speed sensor module

This speed sensor has an optical sensor that allows you to measure revolution per minute (RPM).

x2robotics.ca

USB power adapter

case, etc.

*/

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

LiquidCrystal_I2C lcd(0x27, 20, 4);

// SDA pin A4

// SCL pin A5

volatile float time = 0;

volatile float time_last = 0;

volatile int rpm_array[7] = {0, 0, 0, 0, 0, 0, 0};

void setup()

{

//Digital Pin 2 Set As An Interrupt

attachInterrupt(0, fan_interrupt, FALLING);

// set up the LCD's number of columns and rows:

lcd.begin();

// Print the main header to the LCD.

lcd.setCursor(0, 0);

lcd.print("Current RPM: ");

}

void loop()

{

int rpm = 0;

while (1) {

//Slow Down The LCD Display Updates

delay(500);

// fill array of cutter diameters

float CutterSixteens[] = {1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 20, 24, 32, 40, 48, 64}; // cutter diamters in sixteenths

char* CutterNames[] = {"1/16\" ", "1/8\" ", "3/16\" ", "1/4\" ", "5/16\" ", "3/8\" ", "7/16\" ", "1/2\" ", "9/16\" ", "5/8\" ", "11/16\"", "3/4\" ", "13/16\"", "7/8\" ", "15/16\"", "1\" ", "1-1/4\"", "1-1/2\"", "2\" ", "2-1/2\"", "3\" ", "4\" "}; // cutter descriptions in text

int HSSsfm[] = {300, 150, 100, 80, 50, 90, 80, 40, 50, 60, 40, 175, 500}; // book values for SFM for materials

// Set cutter diameter

int CutterDial = analogRead(A2); // 10K pot wiper to analog Pin 2

int Cutter = map(CutterDial, 0, 1023, 0, 21); // maps pot to 1 of 12 cutter diamters

char* MatNames[] = {"ALUMINUM ", "BRASS ", "COPPER ", "SOFT IRON ", "HARD IRON ", "MILD STEEL ", "CAST STEEL ", "ALLOY STEEL", "TOOL STEEL ", "S-STEEL 303", "S-STEEL 316", "PLASTICS ", "WOOD "};

// Set material

int MatList = analogRead(A1); // 10K pot wiper to analog Pin 1

int Material = map(MatList, 0, 1023, 0, 13); // maps pot to 1 of 14 material types

float SFM = (((CutterSixteens[Cutter] / 16) * rpm) / 3.82);

int smoothedSFM = SFM * .2; // divided by five to get to multiples of five

int displaySFM = smoothedSFM * 5; // restores by 5 to get back to rounded x 5 sfm

// cutter rpm = sfm x 3.82 / cutter diameter in inches

// sfm = rpm x cutter diameter in inches / 3.82

// cutter diamters from array is in sixteenths

int HSBookRPM = ((HSSsfm[Material]) * 3.82 / ((CutterSixteens[Cutter]) / 16));

int calmeddisplayRPM = rpm /5; // divided by five to get to multiples of five

int displayrpm = calmeddisplayRPM * 5; // restores by 5 to get back to rounded x 5 rpm

//Clear The Bottom Row

lcd.setCursor(13, 0);

lcd.print(" ");

//Update The Rpm Count

lcd.setCursor(13, 0);

lcd.print(displayrpm);

lcd.setCursor(0, 2); // prints out cutter size on line 3

lcd.print(CutterNames[Cutter]);

lcd.setCursor(7,2);

lcd.print("cal rpm "); //prints out calculated rpm and restricts to 2000 max

if (HSBookRPM > 2000){

lcd.print(">2000");

}

else {

lcd.print(HSBookRPM);

lcd.print(" ");

}

lcd.setCursor(0, 1);

lcd.print("Current SFM: ");

lcd.setCursor(13, 1);

if (displaySFM <5){

lcd.print("<5");

}

else {

lcd.print(displaySFM);

lcd.print(" ");

}

lcd.setCursor(0, 3); // prints material name on line 4

lcd.print(MatNames[Material]);

lcd.print(" "); //kills trailing zero

lcd.setCursor(12,3); // prints material sfm on line 4

lcd.print("sfm ");

lcd.print(HSSsfm[Material]);

lcd.print(" ");

//Update The RPM

if (time > 0)

{

//5 Sample Moving Average To Smooth Out The Data

rpm_array[0] = rpm_array[1];

rpm_array[1] = rpm_array[2];

rpm_array[2] = rpm_array[3];

rpm_array[3] = rpm_array[4];

rpm_array[4] = rpm_array[5];

rpm_array[5] = rpm_array[6];

rpm_array[6] = 60 * (1000000 / (time * 16)); //(time x pulses per revolution) - mill quill has 16 perforated holes around circumference

//Last 5 Average RPM Counts Eqauls....

rpm = (rpm_array[0] + rpm_array[1] + rpm_array[2] + rpm_array[3] + rpm_array[4] + rpm_array[5]+ rpm_array[6])/ 7;

}

}

}

void fan_interrupt()

{

time = (micros() - time_last);

time_last = micros();

}