Just for info only, mostly for the benefit of anyone who likes to gronk on t-bolts, here is a number to remember.

Very roughly, it takes just 10 ft-lbs of torque on a 1/2 inch bolt to generate over 1000lbs of tensile clamping force. The actual number depends on the thread quality, pitch, and condition, and the presence of grease/oil on the threads.

To visualize this, think of 1000 plus pounds of force pushing your vise against the table at each T-Bolt. Two 1/2 inch T-Bolts is over a ton of force. That vise isn't going anywhere. Yes, bolts are very strong and can apply huge amounts of force. We often underestimate just how much force we can generate through the magic of thread leverage. As Archimedes said, "if you give me a lever and a place to stand, I can move the world!"

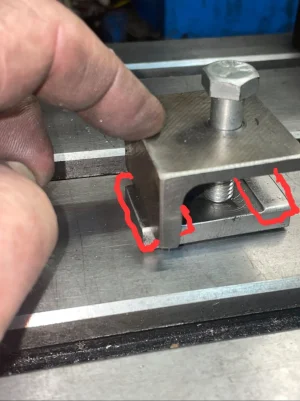

What happens when you gronk on the bolt? 100 ft-lbs is quite easy to apply. But 100 ft-lbs generates well over 10,000 pounds of compression force per bolt. It becomes very easy to see why non supported loads or bottomed bolts can so easily break a T-slot.

My main message here is that you don't have to gronk on those bolts to secure a vise (or anything else) to the table.

If you have a fully contiguous compressed column of metal without any gaps, you can freely add more torque, but it isn't needed. For most situations, a 10 pound pull on a foot long wrench is plenty.

Very roughly, it takes just 10 ft-lbs of torque on a 1/2 inch bolt to generate over 1000lbs of tensile clamping force. The actual number depends on the thread quality, pitch, and condition, and the presence of grease/oil on the threads.

To visualize this, think of 1000 plus pounds of force pushing your vise against the table at each T-Bolt. Two 1/2 inch T-Bolts is over a ton of force. That vise isn't going anywhere. Yes, bolts are very strong and can apply huge amounts of force. We often underestimate just how much force we can generate through the magic of thread leverage. As Archimedes said, "if you give me a lever and a place to stand, I can move the world!"

What happens when you gronk on the bolt? 100 ft-lbs is quite easy to apply. But 100 ft-lbs generates well over 10,000 pounds of compression force per bolt. It becomes very easy to see why non supported loads or bottomed bolts can so easily break a T-slot.

My main message here is that you don't have to gronk on those bolts to secure a vise (or anything else) to the table.

If you have a fully contiguous compressed column of metal without any gaps, you can freely add more torque, but it isn't needed. For most situations, a 10 pound pull on a foot long wrench is plenty.