I noticed a definite improvement of surface finish after I balanced my wheel.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Surface Grinding Textbook

- Thread starter TOBARApprentice

- Start date

The standard is a Starrett Webber and is 26”. According to the certification and the Starrett paperwork it is dimensionally stable as it pertains to temp and the blocks are in some way insulated. I’ll post the spec sheet/literature later today. Try a bit more flap for your takeoff in the Concorde, use the afterburner and give yourself 10-15 kts of headwind. Depart 33R at CYYZ. If that doesn’t work you are doing something wrong (taking off over gross wt, lol).

Love to see the specs!

You may be onto something with the Concorde. Gross weight is within specs but the sim won't let me engage the after burners..... I had assumed it wasn't allowed until after hitting a given elevation or a given airspeed. But that's a problem I can prolly fix. THANK YOU!

140mower

Don

A couple books I have, the first one General Engineering Workshop Practice is my favorite machine tool book. It's written in a manner that I enjoy reading and covers most of the machine tools and practices found around the 1940's or there abouts.

The second is also from the early 40's and covers a large range of grinding operations. I confess, I haven't read the second book yet, as I am not yet set up to grind.

My tools range from about 1913 to 1978 in age with most being 1940 and previous, hence my little library being focused on that period of time.

The second is also from the early 40's and covers a large range of grinding operations. I confess, I haven't read the second book yet, as I am not yet set up to grind.

My tools range from about 1913 to 1978 in age with most being 1940 and previous, hence my little library being focused on that period of time.

Attachments

140mower

Don

One other I dug out is "Machine Shop Training Course" volume 2 which has a pretty detailed section on grinding. I have both volumes, and are relatively recent purchases in a fairly large bunch of books and magazines I picked up to add to the library of sorts.

The copyright range one this set is 1940-1964, also written in a manner that intends to teach young minds.

The copyright range one this set is 1940-1964, also written in a manner that intends to teach young minds.

I LOVE BOOKS!!!

In my personal view they are WAAAY better than YouTube.

First, the author generally has to actually know what they are talking about in order to get published.

Second, I can read them at my leisure and skip over pages that don't interest me. I don't have to listen to someone complain about their camera or or or.

3rd I don't have have to watch adds for adult diapers.

4th One book will cover a Plethora of subjects - all written by a real expert.

5th I don't need a high speed connection I don't have.

6th There is usually an index or at minimum a table of contents.

7th I can read in bed or on the toilet and the wife won't complain.

I know..... Grumpy old man syndrome again....... (Insert big sigh here).

In my personal view they are WAAAY better than YouTube.

First, the author generally has to actually know what they are talking about in order to get published.

Second, I can read them at my leisure and skip over pages that don't interest me. I don't have to listen to someone complain about their camera or or or.

3rd I don't have have to watch adds for adult diapers.

4th One book will cover a Plethora of subjects - all written by a real expert.

5th I don't need a high speed connection I don't have.

6th There is usually an index or at minimum a table of contents.

7th I can read in bed or on the toilet and the wife won't complain.

I know..... Grumpy old man syndrome again....... (Insert big sigh here).

Dabbler

ersatz engineer

@TOBARApprentice Your finish will improve when you balance your wheel. The other telltales are that the wheel needs dressing evenly across the whole bottom surface.

50 millionths is very good. In production grinding, seldom achieved. Bert taught me about grinding, but most of it is what *not* to do...

50 millionths is very good. In production grinding, seldom achieved. Bert taught me about grinding, but most of it is what *not* to do...

TOBARApprentice

Super User

The original motor was balanced so I bought a balanced motor to replace it. It was just shy of $700 but I thought worth it. However the motor shop laughed at be because the connection from the motor to the spindle is a rubber “lovejoy” connection. We’ll see how things shape up over the next while but thanks for the suggestions. Cheers. Derek.Sounds like you've got things lined up well. The only note is that motors for grinders are usually balanced to a high standard so it can be detrimental getting rid of the OEM motor. I did that eons ago when I got my grinder and ended up putting the original motor back on with a noticeable improvement in finish.

Commercial machinists (who are on larger machines) will tell you balancing doesn't matter and they never bother, well, they're right and wrong. It definitely affects things (as in any force does, even a fly landing on it) but their machines are hefty enough it doesn't affect them enough. But on a small light little grinder, you chase away the tiniest source of vibration to the get the best finish.

Chicken lights

Forum Pony Express Driver

I love that the old guys way of “teaching” was reprimands on what not to do@TOBARApprentice Your finish will improve when you balance your wheel. The other telltales are that the wheel needs dressing evenly across the whole bottom surface.

50 millionths is very good. In production grinding, seldom achieved. Bert taught me about grinding, but most of it is what *not* to do...

Repeatedly and loudly, often with working words mixed in

You either couldn’t handle it or you stepped up and hung with the old boys who, in their way, were looking out for you

I love that the old guys way of “teaching” was reprimands on what not to do

Repeatedly and loudly, often with working words mixed in

You either couldn’t handle it or you stepped up and hung with the old boys who, in their way, were looking out for you

I reacted with a love emoticon to that, but a laughing one would have been just as good.

Your comment strikes a very familiar note. I remember one old guy who literally yelled at me constantly. I thought he hated me. But in time, I came to know that he actually saw potential in me that was worth the yelling to bring it out. He was one of the most effective and most important mentors in my life. And no, he wasn't my dad.

My dad used to beat me with his belt when I did something really bad. But he did it with Love. I have no regrets. It was a very fast and effective way to learn. I loved him SOOOO much and I miss him now...... I think it's wrong that the new culture of today would wipe him out of my history. (just my opinion)

GummyMonster

Ken

I'm probably one of the most inexperienced guys on here, but with the accuracy you hit on your first try, I'd say you're very much heading in the right direction.

Good luck.

Ken

Good luck.

Ken

TOBARApprentice

Super User

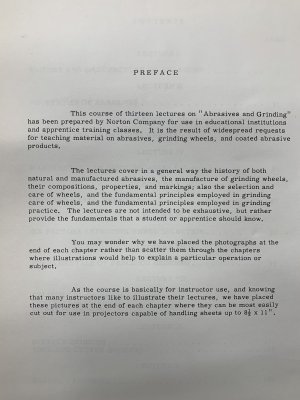

Hey everyone! Just a follow up. I ordered these 4 books on eBay. 3 of the 4 are really useful, the 4th will be listed in the coming days, lol. So….. what have I learned so far?

1. Machine is Level and on Concrete

2. A good wheel with a nice “ring” is on the hub securely and not too tight.

3. Balance the wheel on the hub.

4. Run the machine for about 5 min to warm up.

5. Dress the wheel, bottom and a light touch each side.

6. Re-balance the wheel off the machine. Noting the position from where the hub was removed

7. Remount and restart…..

8. Use a bit of oil or coolant in a spray bottle on the part

9. Get a mirror finish with very light finishing cuts of .0002 to .0004.

I have 8 Boyar Schultz balancing hubs on their way and 5 non balancing hubs which I’ll be parting with in the coming weeks…. Below are the books I purchased. The Norton Lectures and ICS Grinding Practice are the best followed by Grinding Wheels and their uses…..

I’ll let you all know how things go….

Cheers.

Derek.

1. Machine is Level and on Concrete

2. A good wheel with a nice “ring” is on the hub securely and not too tight.

3. Balance the wheel on the hub.

4. Run the machine for about 5 min to warm up.

5. Dress the wheel, bottom and a light touch each side.

6. Re-balance the wheel off the machine. Noting the position from where the hub was removed

7. Remount and restart…..

8. Use a bit of oil or coolant in a spray bottle on the part

9. Get a mirror finish with very light finishing cuts of .0002 to .0004.

I have 8 Boyar Schultz balancing hubs on their way and 5 non balancing hubs which I’ll be parting with in the coming weeks…. Below are the books I purchased. The Norton Lectures and ICS Grinding Practice are the best followed by Grinding Wheels and their uses…..

I’ll let you all know how things go….

Cheers.

Derek.

Attachments

-

DB243782-7F71-4834-8A42-4CB0DEE51D65.jpeg371.5 KB · Views: 8

DB243782-7F71-4834-8A42-4CB0DEE51D65.jpeg371.5 KB · Views: 8 -

566260CC-1714-4484-A8F9-98965FECB7CE.jpeg715.5 KB · Views: 7

566260CC-1714-4484-A8F9-98965FECB7CE.jpeg715.5 KB · Views: 7 -

6B3EB0ED-ECF0-42FB-92A4-0DE94F832641.jpeg329.2 KB · Views: 8

6B3EB0ED-ECF0-42FB-92A4-0DE94F832641.jpeg329.2 KB · Views: 8 -

6131297B-409B-4524-AF1B-202F5992ADD5.jpeg601.8 KB · Views: 8

6131297B-409B-4524-AF1B-202F5992ADD5.jpeg601.8 KB · Views: 8 -

C0277834-DA53-4990-989B-4C503E564A93.jpeg1 MB · Views: 9

C0277834-DA53-4990-989B-4C503E564A93.jpeg1 MB · Views: 9 -

895CDCBC-E668-41F8-BE22-9DFDF28B8D11.jpeg713.2 KB · Views: 9

895CDCBC-E668-41F8-BE22-9DFDF28B8D11.jpeg713.2 KB · Views: 9