catastrophic tactical error imo .... always go with "It's easier to beg forgiveness than ask permission". Be the caveman you were meant to be.

agreed 3D print is a game changer for casting, almost a necessity in my mind given the time savings. Lost resin for small super detailed parts. Lost filament for things a bit bigger and not as demanding detail/finish wise. For things that would fit in up to say a large soup can, investment and vacuum casting is amazing. For larger than that, it's mostly outside of my experience (some AL in sand, open top, but that was 35 years ago). I'm a secret basement caster in an urban setting who wants to keep things very low key Running a larger furnace and sand casting in back yard or drive way isn't happening. If I get back to the country one day, maybe, but even then it will be based on 3D printed patterns..... the time savings is incredible over having to make a pattern.

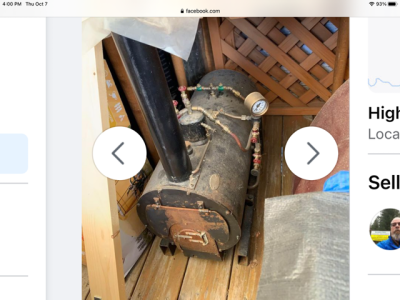

I've posted this before, but here is a sample of lost resin detail. A bronze elbow for a live steam model engine with fake flange, bolts and nuts .... copper tube gets silver soldered into it. Incredible detail - those bolts are 1/16" dia!. It's also far more difficult than lost filament, with lots of fails and experiments each taking a weekend, between actual work, print and burnout time.

View attachment 58790