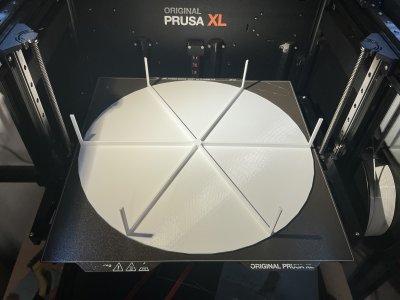

My spouse thinks it from a 1970s sci-fi show - something from the medical bay. Haha. It’s really cool I think. I want to see some alien plants. Egg plant, Venus fly traps, triffids….OK. I've had BadaBambu now for a week. I've gone through 4 spools of filament already including reprinting two pieces but this time using the support filament which is only used as a thin layer between the actual printing PLA. Mostly the issue with the support filament doing curves that arc upwards is lots of swapping filament back and forth. This is where a multi-extruder unit would be more effective.

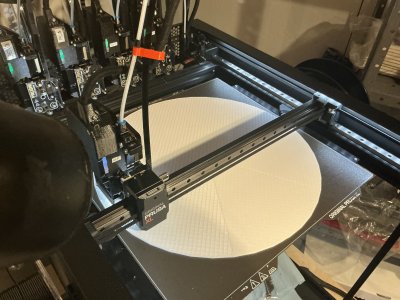

What I like most about the Bambu X1C though is that the bed doesn't move back and forth and so the XY motion is so much faster and smoother. What takes 2 hours on the SOVOL takes half that time on the Bambu.

The surface finish on a piece that was supported is simply amazing compared to the old way of doing it with the same filament. Amazon is supposed to deliver the 5mm diameter magnets today so I can put those into both the frame and the doors and then use them to correctly position everything when I glue the frame together.

I haven't decided yet if I want to use the 4xRed_1xBlue LED tape or the led strip with the REDish Blue LEDs for the grow light trays.

Also not yet decided on the plant probes and auto watering system.

View attachment 55520

Edit: It's 16"x10"x24"

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

So I've jumped into the rabbit hole

- Thread starter Dabbler

- Start date

Omg you said trifids. Great scifiMy spouse thinks it from a 1970s sci-fi show - something from the medical bay. Haha. It’s really cool I think. I want to see some alien plants. Egg plant, Venus fly traps, triffids….

Funny you should lump Egg plant in with Triffids. However last time I planted Triffids they caused all sorts of havoc so I was kind of thinking this time planting Triffids was not really a good idea. Plus anytime I shipped them FedEx the entire truck vanished.My spouse thinks it from a 1970s sci-fi show - something from the medical bay. Haha. It’s really cool I think. I want to see some alien plants. Egg plant, Venus fly traps, triffids….

pdentrem

Well-Known Member

I do have a .8 nozzle but I have yet to use it. All my extruders currently have .4 nozzles.Just look at that printer! @pdentrem have you done any mixed diameter nozzle prints, say 0.8mm for coarse fast areas, and a 0.4mm for threads and lettering etc. How does that work out?

How are you using the multiple heads in practice?

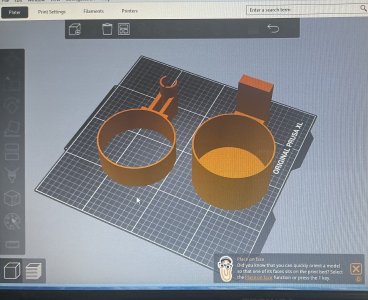

I have used 3 nozzles at one time. Support material, main body of the part and text. Here just 2 nozzles as I was just trying text on test pieces. The top one was without a wipe tower, while the bottom one was dried again and with the wipe tower. Both are Petg.

Pierre

pdentrem

Well-Known Member

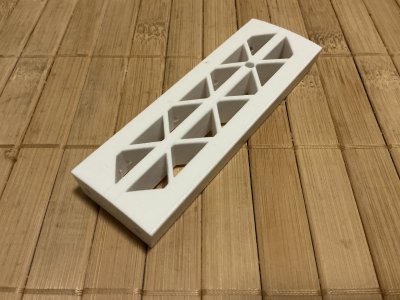

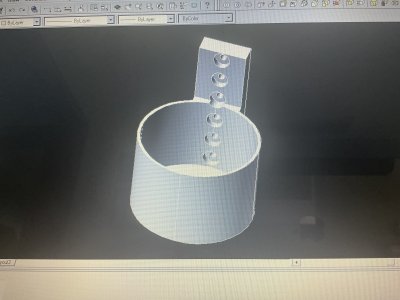

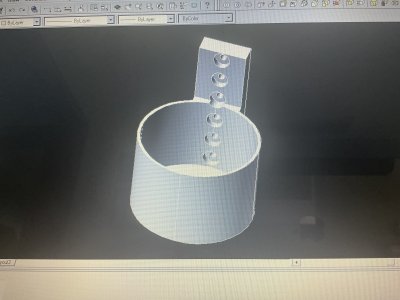

Did a test piece, in white, to see if there were any issues before going full size. I did find an issue for a bolt. I had earlier printed a solid piece which you can see in the back of the 2 hoops. I now have to print 3 more of the skeletonized parts.

Pierre

Pierre

Attachments

pdentrem

Well-Known Member

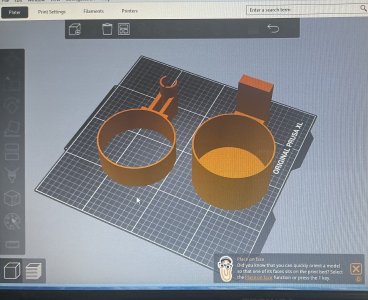

It seems that people with walkers have issues with lugging an oxygen bottle. Either it is slung across the handles, or into the basket, or precariously placed on the seat. I printed these for a friend last weekend. In her situation the left one clips to the upright tube under the handle and the right one uses a block of wood and pinches the lower tubes between it and the cup that the bottle sits in. The lady for the oxygen service was there at the time and noted what I was installing. She said others are in need of similar for their walkers. I had seen files for wheel chairs but not walkers in my search online.

I have modified the file to include an array of bolts holes to allow some flexibility in mounting the lower cup.

Pierre

I have modified the file to include an array of bolts holes to allow some flexibility in mounting the lower cup.

Pierre

Chris Cramer

Super User

As much as I know about nonmetalic 3d printers I would only use them for modeling purposes or plastic components that don't take much wear and tear. I built my own 3d printer with stepper motors using a belt drive for the nozzle gantry, and lead screws for the hot bed. The machine's controller that I got from big tree tech can operate the machine in manual mode, but it was unable to upload and operate in g code. I've been thinking of using a cnc shield with an arduino micro controller to replace the faulty controller but I'm not sure if that could be used for 3d printing as it is most often used for laser engraving with laser grbl.

Chris Cramer

Super User

As much as I know about nonmetalic 3d printers I think I would only use it for modeling purposes or for plastic components that don't take much wear and tear. How reliable are 3d printed parts anyway?

I built my own 3d printer with stepper motors to run a belt drive for the nozzle gantry, and lead screws for the hot bed. The controller I used from big tree tech could run the machine manually, but it could not upload and read g code. I've been thinking about using an arduino micro controller with a cnc shield to replace the faulty controller, but I'm not sure if that would work for 3d printing since it's most often used for laser engraving with laser grbl.

I built my own 3d printer with stepper motors to run a belt drive for the nozzle gantry, and lead screws for the hot bed. The controller I used from big tree tech could run the machine manually, but it could not upload and read g code. I've been thinking about using an arduino micro controller with a cnc shield to replace the faulty controller, but I'm not sure if that would work for 3d printing since it's most often used for laser engraving with laser grbl.

Attachments

pdentrem

Well-Known Member

The robotics teams use lots of 3D printed parts and used as the frame and outer protection. Surprisingly robust in the combat theater! This is not in the unlimited class, in the lower power levels with spinning disk impactors etc.

Printed gears for lathes in nylon are fairly common to replace lost change gears.

Printed gears for lathes in nylon are fairly common to replace lost change gears.

pdentrem

Well-Known Member

Slitting saw now has a home as well. I printed the saw rack vertically to avoid using supports. Could of added 1 maybe 2 more slots, obviously if the blades were vertical more could be stored in the same space, but I was limiting the space required to allow it to fit in lower height drawers. It fit first try with no adjustments! Lucky.

PS I am now printing a new blade box to remove that wasted space!

Pierre

PS I am now printing a new blade box to remove that wasted space!

Pierre

Last edited:

@pdentrem I like your tooling cases. I had a similar idea for before acquiring 3DP for my box-less micrometer is sitting in an aftermarket Tupperware-like box with some rudimentary foam padding. I was wondering about how to make a clasping or otherwise closed box. Looks like some people print integral hinges. I think my Mit box has flexure like tabs that act as hinges, I should look closer. Did you try any generic hinged lid designs to see how they print & snap shut etc?

Even a mini caliper box

Even a mini caliper box

pdentrem

Well-Known Member

Not yet. I saw one micrometer box with lid on Printables. It used a piece of filament as the hinge pins. I will investigate this style.

www.printables.com

www.printables.com

50-75mm Micrometer Case by GreatOldOne | Download free STL model | Printables.com

A micrometer case for a Mitutoyo micrometer - it may fit other brands, but you will need to check fit / sizing. | Download free 3D printable STL models