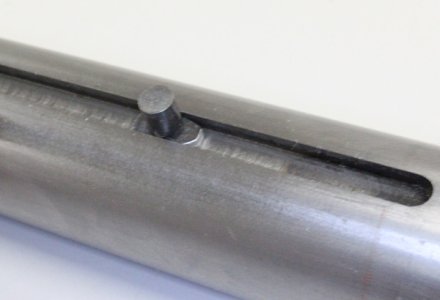

Good for you Chris. Nice work.Finished shaft:

I ended up using a 'floating' tailstock die holder to do the threads instead of single point threading them.

My neighbours CX709 lathe has metric dials. This was my first lathe project since high school 30-ish years ago, so between re-familiarizing myself with 'touching off', 'zeroing' my dials, and the switching back and forth between metric and imperial (my mics are imp) in my head was confusing and I screwed up my first two attempts. Good thing the 15mm drill rod I got from KBC was 3 feet, lol.

I should add that my neighbour had a bag of the standard 'blue' (BusyBee/KMS, etc) brazed on carbide tools that came with his used CX709 which were all size '8' (1/2" shank) and he was using a jury rigged set of shims to set them to the lathe centerline. This didnt look right to me, so I did some reading and it seemed that I needed size '10' tools (5/8" shank). A quick trip to KMS and $30 bucks later and I had teh correct tooling to do the work without screwing around with a bunch of shims.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small shaft repair options?

- Thread starter calgaryguy

- Start date

I spin my MT2 tailstock tapers all the time, it's quite annoying. Not all tailstock spindles provide a means to utilize a tang.

Oh, I'm not at all surprised that it spun. That's one reason why I don't really like MTs.

What I am surprised about is that it spun with a tang on it. I didn't think that was possible at all.

I think what @YYCHM is saying is if the tailstock doesn't have the tang receptacle, then its only the taper friction holding it in position regardless if a tank is on the arbor. My 14x40 does not have one either.

Anyways, good job @calgaryguy , hopefully you have a functioning machine real soon now

Anyways, good job @calgaryguy , hopefully you have a functioning machine real soon now

Just a follow up potential word of caution on these big die threading jobs. I know lathe tail stocks vary by machine, but what seems to be quite common on the hobby class machines is a longitudinal keyway slot down the length of the quill barrel, typically on the underside. The slot engages a kind of key looking part which is retained in the TS casting hole with an integrated pin. I think this is primarily intended to align the barrel as it extends & retracts so the engraved scale stays on top & keep it 'somewhat' locked for the purposes of cutting tools.

On many machines as mentioned above, there is no tang receptacle inside the TS housing that acts on the tang flats of arbors. The tank just passes into an open hole. So from what I can tell, at least on my 14" lathe, this keyway/pin is the last line of defense if loads get high. If the tool shank spins under load, yes its inconvenient. Might even scour & bugger up the socket surface. But if the tool becomes locked or seized in the socket, its also possible to (pick your poison) shear the pin, bugger or jamb the key shoe, bugger the slot, ovalize the quill barrel. None of those are fun remedial options. A safer way might be to just use the TS die holders for a few threads of initial alignment & once engaged, just get out the conventional die wrench & finish the threading. Your arms might get tired but the TS is not at risk. Someone posted a picture of threading with a die handle under low rpm power with the die handle resting on wood on the cross slide, another option.

On many machines as mentioned above, there is no tang receptacle inside the TS housing that acts on the tang flats of arbors. The tank just passes into an open hole. So from what I can tell, at least on my 14" lathe, this keyway/pin is the last line of defense if loads get high. If the tool shank spins under load, yes its inconvenient. Might even scour & bugger up the socket surface. But if the tool becomes locked or seized in the socket, its also possible to (pick your poison) shear the pin, bugger or jamb the key shoe, bugger the slot, ovalize the quill barrel. None of those are fun remedial options. A safer way might be to just use the TS die holders for a few threads of initial alignment & once engaged, just get out the conventional die wrench & finish the threading. Your arms might get tired but the TS is not at risk. Someone posted a picture of threading with a die handle under low rpm power with the die handle resting on wood on the cross slide, another option.

Last edited:

On many machines as mentioned above, there is no tang receptacle inside the TS housing that acts on the tang flats of arbors. The tank just passes into an open hole.

I didn't know that there were any MT3 recievers that didn't have the tang receptacle. That explains the mystery for me. Thank you.

A safer way might be to just use the TS die holders for a few threads of initial alignment & once engaged, just get out the conventional die wrench & finish the threading. Your arms might get tired but the TS is not at risk. Someone posted a picture of threading with a die handle under low rpm power with the die handle resting on wood on the cross slide, another option.

I don't think I would ever have the guts to cut threads under power with the die held in an MT3 taper.

I did make a special bar that sits on a wood block on the ways that I use to stop the chuck from turning while I manually turn the die in a die holder that is aligned in the tail stock. But even then I try to use two hands (one on each side of the die holder) to avoid uneven forces.

Frankly, I enjoy single point threading so much that it is very unusual for me to use a die on the lathe anyway. I often use a tap instead of inside threading though.

calgaryguy

Chris

My feeling is inaccurate or poorly ground MT3 taper on the threading tool or on the tailstock receiver side. Once I seated the taped *firmly* it held.I

I confess that I am shocked that it spun. Usually tapers with the tang tip do not (actually can not) spin except for a few degrees when the tang catches.

And before anyone jumps on me, yes I know that's not the purpose of the tang nor good practice, nor would I ever use it that way.

It is just that I am shocked and find myself wondering how that is possible.

Blondihacks did a thing a while ago IIRC where she blued up a taper to check the tailstock fitment on a cheaper chinese made taper and the bluing was a poor fit.

calgaryguy

Chris

You know it really was easy. I set the gearbox for its slowest speed (65rpm) and slowly advanced the tailstock handwheel until the die 'bit' and watched it advance itself onto the rod, with my hand at teh ready to stop the lathe spindle just before it hit the end of the shoulder. There was no use of the power feed - once the die started to thread itself, the lathe spindle did all the work.I don't think I would ever have the guts to cut threads under power with the die held in an MT3 taper.

calgaryguy

Chris

In other news, I put down a deposit on a SM 1000 Utilathe this AM, and I'll be picking it up Thursday-Friday. Former SAIT in Calgary machine. Its had some crossfeed/toolpost <-> chuck interactions in its life but the backlash in the various dials seemed really good, even better than teh neighbours new-ish CX709. Ways are a little dinged up close to the chuck but not horrible compared to a couple of this vintage I've looked at. 3+4 jaw, some tooling, taper attachment but no steady or follower rests.

calgaryguy

Chris

Funny, I actually looked at SAIT's calendar the other day to see if they offered anything like this anymore - they dont seem to. NAIT in Edmonton still seems to offer a course.Nice! Those lathes are sweet machines. I did a continuing ed machining course at SAIT some years ago, that was a lot of fun. Who knows, maybe I even used that very same machine. I never crashed the toolpost, I swear.

Even the 'Certificate Of Achievement In Cabinetmaking' evenings and weekend program (5 x 4 week courses) I completed a few years ago doesnt seem to be offered anymore at SAIT. A shame really.

Last edited:

Six O Two

(Marco)

Funny, I actually looked at SAIT's calendar the other day to see if they offered anything like this anymore - they dont seem to. NAIT in Edmonton still seems to offer a course.

Even the 'Certificate Of Achievement In Cabinetmaking' evenings and weekend program (5 x 4 week courses) doesnt seem to be offered anymore at SAIT. A shame really.

Man, that totally is a shame. Just taking a quick peek at SAIT's ConEd offerings and it really looks like they're de-emphasing trades in general. No auto mechanics, no woodworking, no metal working. At least they've still got welding classes.

Thank goodness for this place and youtube...

calgaryguy

Chris

Maybe youtube and forums are partly to blame?Man, that totally is a shame. Just taking a quick peek at SAIT's ConEd offerings and it really looks like they're de-emphasing trades in general. No auto mechanics, no woodworking, no metal working. At least they've still got welding classes.

Thank goodness for this place and youtube...

I had been messing with woodworking since I was a kid with my grandpa. That certificate program I took at SAIT really solidified my knowledge and confidence in the WW space. I wanted to do the same with a basic intro to machining.

Six O Two

(Marco)

Maybe youtube and forums are partly to blame?

I had been messing with woodworking since I was a kid with my grandpa. That certificate program I took at SAIT really solidified my knowledge and confidence in the WW space. I wanted to do the same with a basic intro to machining.

Judging from machine prices, the sector seems to be growing, and maybe youtube is playing a part. Watching videos is one thing, but I know I certainly greatly benefited from in-person, hands-on guidance over the years, especially when we're talking about machines with serious horsepower - table saws, bandsaws, lathes and mills.

The lack of courses at SAIT is a strange thing. There is loads of evidence people want to do hands on stuff more and more. Maker spaces, high tooling prices, used machines are gone instantly, lots of people 3d printing. I think half the problem for SAIT is the incredibly poor course descriptions and promotion they do.Judging from machine prices, the sector seems to be growing, and maybe youtube is playing a part. Watching videos is one thing, but I know I certainly greatly benefited from in-person, hands-on guidance over the years, especially when we're talking about machines with serious horsepower - table saws, bandsaws, lathes and mills.