slow-poke

Ultra Member

I think I paid about US$100 for each of my Metcal stations, used on eBay.Especially the hold temp but still pour heat into the work. I hate to ask, what that costs!

I think I paid about US$100 for each of my Metcal stations, used on eBay.Especially the hold temp but still pour heat into the work. I hate to ask, what that costs!

I'm not really up to speed on the Weller stuff, but possibly ETS or ETH or ETU, ETV , but confirm compatibility with WES51Question for those with more experience than me (almost everyone here) in soldering these micro-components: I have a Weller WES51 soldering station. What size tip should I use? I currently only have the tip that came with the unit, and it's large enough to solder door hinges on a Ram 2500. Well not quite, but compared to the resistors it's huge.

Yes, many of the PCB houses offer a population service. You need to provide the P&P file, but that's just a mouse click with good software. Generally you would want to be making a reasonable number of boards because they need to program and load the pick and place machine with the required components so the setup costs are high for low quantity runs, and cheap in volume. For example the TouchDRO board described above would probably be about $5-10 a pop populated in volumeGents - if ordering custom pcb boards is so cheap what if you wanted them to just make the whole thing? Sometimes the making is the fun but sometimes it is getting on with the other things you want to do with your project. Does PCway or these other companies do that?

Or how about an even higher level approach - say I want a solution to control a custom machine using gcode (or maybe something else - C#? - Java - something OO?) and different parts of the machine need their own Gcode "Subroutines" to do something with a sub module of the machine? Do you design 3 interconnected machines and handoff from one to the next? Or do you have a master machine which issues commands to the 3 machines?

Besides @slow-poke who is retired are there companies that do this sort of thing but not charge $50K?

Super interesting thread!

Those are compatible, so this helps.I'm not really up to speed on the Weller stuff, but possibly ETS or ETH or ETU, ETV , but confirm compatibility with WES51

How many is 'volume'? 10? 100?For example the TouchDRO board described above would probably be about $5-10 a pop populated in volume

I guess I mean how would you connect different "sections" of a machine, or maybe they are separate machines, together. Just musing here - Say your band saw has a control to cut up stock, and a robot arm to grab the pieces and load them into your mill with an automatic vise, the program runs on the mill, and then the arm unloads the part and puts it into the spray booth where it is painted. How would scenarios like this be managed? A single master control controlling those machines to do their operations - or would each machine tell the next - ready for you - and then the first machine gets on with the next operation. @Susquatch I bet you have several answers and yes I'm dragging you out of retirement to think about it!I don't entirely follow "the different parts of the machine need their own routines"?

@Susquatch I bet you have several answers and yes I'm dragging you out of retirement to think about it!

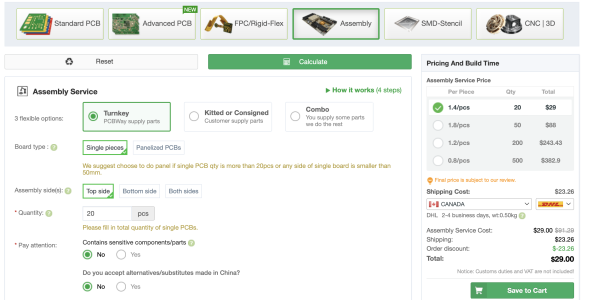

The boards I ordered will arrive later today, so I still can't speak to the quality, but assembly from PCBway SEEMS to be $29 USD for 20 boards. I don't know what the additional costs would be for components.How many is 'volume'? 10? 100?

I guess I mean how would you connect different "sections" of a machine, or maybe they are separate machines, together. Just musing here - Say your band saw has a control to cut up stock, and a robot arm to grab the pieces and load them into your mill with an automatic vise, the program runs on the mill, and then the arm unloads the part and puts it into the spray booth where it is painted. How would scenarios like this be managed? A single master control controlling those machines to do their operations - or would each machine tell the next - ready for you - and then the first machine gets on with the next operation. @Susquatch I bet you have several answers and yes I'm dragging you out of retirement to think about it!

Brings to mind an elephant trying to text. And I have enough trouble texting accurately.I snapped an image to show relative tip and component sizes.

This board was done in 2010, and could be soldered by hand. The DSP chip is only 176 pins with 0.5mm pin spacing so not dense by any means compared to say the high density packages on the QorIQ board I showed above.

R64 is 0603

The large tip just to the left of "DSP" is probably similar size to your existing Weller tip

The small tip next to R64 (0603 black resistor) is a STTC-145 (0.4mm wide tip).

Now the small part...... same STTC-145 tip next to a 01005 10k resistor, the entire component is about the size of the one pad of the 0603. Forget about hand soldering these little guys you need a good quality P&P machine to do work this small.

View attachment 54617

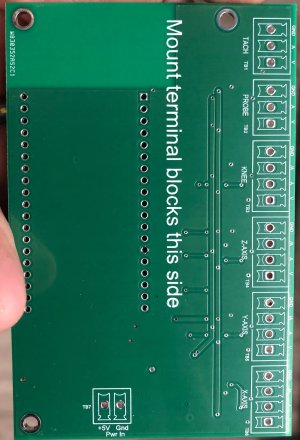

My boards arrived! They look good to my uneducated eye.How many is 'volume'? 10? 100?

I guess I mean how would you connect different "sections" of a machine, or maybe they are separate machines, together. Just musing here - Say your band saw has a control to cut up stock, and a robot arm to grab the pieces and load them into your mill with an automatic vise, the program runs on the mill, and then the arm unloads the part and puts it into the spray booth where it is painted. How would scenarios like this be managed? A single master control controlling those machines to do their operations - or would each machine tell the next - ready for you - and then the first machine gets on with the next operation. @Susquatch I bet you have several answers and yes I'm dragging you out of retirement to think about it!

So Tom they would have made 20 boards with components for $29. ? Really?The boards I ordered will arrive later today, so I still can't speak to the quality, but assembly from PCBway SEEMS to be $29 USD for 20 boards. I don't know what the additional costs would be for components.

I thought about given this a try for the boards I ordered, but doing it will be half the fun!

View attachment 54627

As I mentioned in the original post, components would be on top of this. This is just the assembly.So Tom they would have made 20 boards with components for $29. ? Really?

Somebody these shops offer ridiculously good rates if you assemble your board out of their supported components. I assume they have pick-and-place machines stocked with common prototyping parts. If you're assembling simple logic next to a microcontroller you can likely do it with a pretty small variety of parts.As I mentioned in the original post, components would be on top of this. This is just the assembly.

At least that's how I read the information.

And I think it's likely an introductory offer. Just based on life experience.

That's for sure.... these shops offer ridiculously good rates.

And I think testing time will be where they cut corners. Like you are the testing department.That's for sure.

If you have ever observed the process of solder paste, loading and programming the P&P machine, and then running it through the oven, post inspection it would be more than obvious they are loosing money on every order like this. Local pricing would be in the thousands of dollars for 10 boards.

Watching a P&P machine and flying probe test is really cool.

I designed quite a number of those production style test fixtures, they save an incredible amount of testing time, made a bunch that reduced testing time from 6 hours to 2 minutes and was a much much more thorough test. The initial testing actually discovered some flaky design in the product that was causing intermittent failures in the field and they had been shipping them like that for a couple of years.