TorontoBuilder

Sapientia et Doctrina Stabilitas

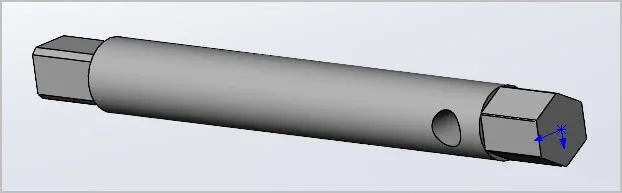

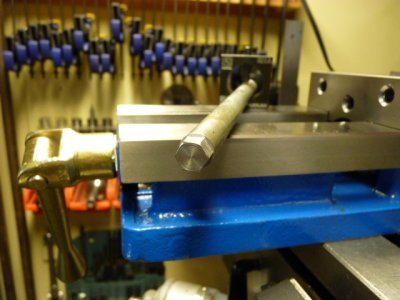

I can't wait to get mine...First project today ! Second Lathe chuck key for the four jaw. A simple square end but also a 45 degree feature (cross drill) for the handle. Rose index was handy.

I can try to make a slightly larger key to fit one of the cams on my chipmaster spindle that someone bashed up trying to free a stuck cam that was or still is preventing the chuck removal.