Trust is a dangerous game! I'm sure the concentricity is within some tolerance...but what that is, who can say until you actually measure. And the manufacturer's muzzle brake will be designed around those tolerances. Looser the tolerance at the threads, means larger the brake bore...(for safety and liability issues).Back to muzzle devices- can you trust factory threads on a barrel to have concentric ID to OD parameters? or as @Susquatch pointed out would the factory care about such tolerances?

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rifle Action Truing

- Thread starter thestelster

- Start date

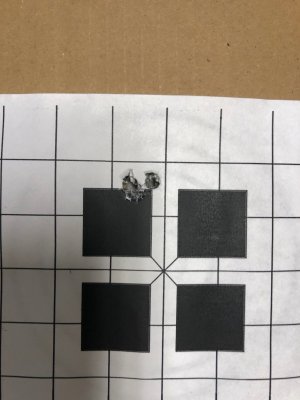

Here is one of the first targets from the new barrel and all the work that went into the action. 3 shot group, 280 Ackley Improved, Nosler 140gr. Ballistic Tip factory ammo. Original wood stock, no bedding. Looks less than 1/2" group. Barrel is still not broken in yet, and I'm sure with a good pillar bedding job and good reloads, it will get much tighter.

Attachments

Back to muzzle devices- can you trust factory threads on a barrel to have concentric ID to OD parameters? or as @Susquatch pointed out would the factory care about such tolerances?

The factory will do ok within their tolerances. For liability and cost reasons, those tolerances will be quite wide. If they always did a perfect job, there would be no need for custom work. Similarly, not everyone wants, needs, or can afford custom work - assuming they can even shoot well enough to see the difference. So there is a demand for factory hardware.

It's all a bit of a crap shoot though. Sometimes factories build a tack driver. More often they don't. The better factories have better averages.

Chicken lights

Forum Pony Express Driver

True, and mixing one barrel manufacturer with another brake manufacturer is going to make it even more of a guessing game, for tolerances.Trust is a dangerous game! I'm sure the concentricity is within some tolerance...but what that is, who can say until you actually measure. And the manufacturer's muzzle brake will be designed around those tolerances. Looser the tolerance at the threads, means larger the brake bore...(for safety and liability issues).

Can someone with your skills “fix” barrel threads to be more concentric? I’m guessing no, unless starting with a brake that was undersized.

Chicken lights

Forum Pony Express Driver

True. I fall into the no need for custom work category, however it’s an interesting rabbit hole to chase. It’s probably a leftover from playing mechanic, you need to know what the thing is supposed to do, in order to diagnose it before fixing itThe factory will do ok within their tolerances. For liability and cost reasons, those tolerances will be quite wide. If they always did a perfect job, there would be no need for custom work. Similarly, not everyone wants, needs, or can afford custom work - assuming they can even shoot well enough to see the difference. So there is a demand for factory hardware.

It's all a bit of a crap shoot though. Sometimes factories build a tack driver. More often they don't. The better factories have better averages.