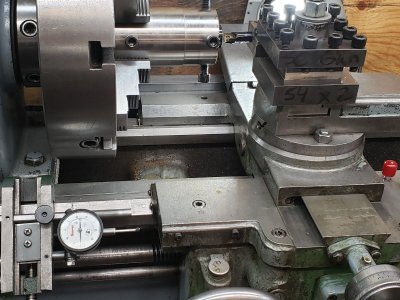

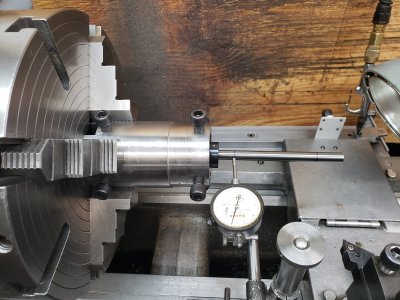

Yesterday I machined 10 flutes onto a barrel. Today we start the action and bolt truing. To achieve maximum accuracy in a rifle, all the surfaces which make contact with the barrel have to be true. The internal action threads, the action face, the recess where the bolt lugs lock into, all have to be concentric to the bore of the action where the bolt slides. They seldom are. So first we have to put the action into the lathe so we can do the work.

Attachments

-

20220207_111848.jpg116.1 KB · Views: 39

20220207_111848.jpg116.1 KB · Views: 39 -

20220207_114311.jpg480.3 KB · Views: 40

20220207_114311.jpg480.3 KB · Views: 40 -

20220207_115559.jpg312.4 KB · Views: 38

20220207_115559.jpg312.4 KB · Views: 38 -

20220207_120636.jpg398.3 KB · Views: 37

20220207_120636.jpg398.3 KB · Views: 37 -

20220207_121000.jpg382 KB · Views: 38

20220207_121000.jpg382 KB · Views: 38 -

20220207_124924.jpg441.5 KB · Views: 38

20220207_124924.jpg441.5 KB · Views: 38 -

20220207_130948.jpg460.5 KB · Views: 38

20220207_130948.jpg460.5 KB · Views: 38 -

20220207_134843.jpg285 KB · Views: 40

20220207_134843.jpg285 KB · Views: 40