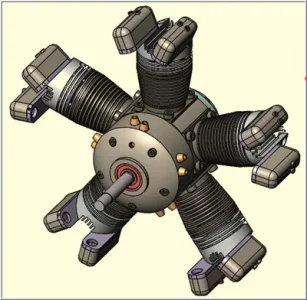

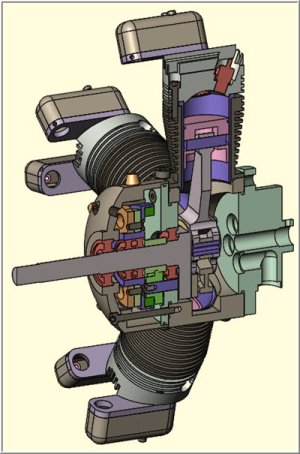

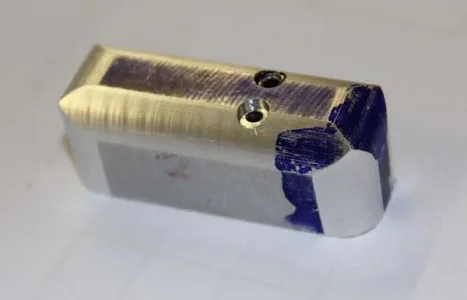

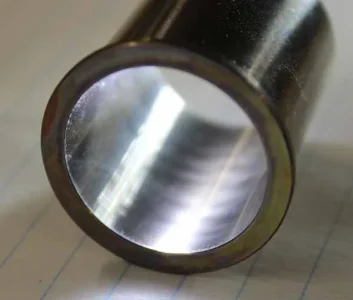

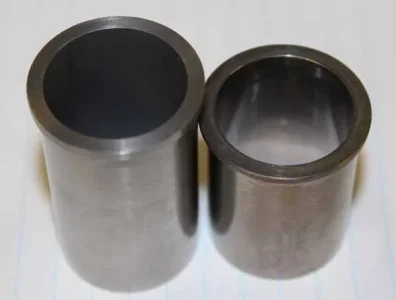

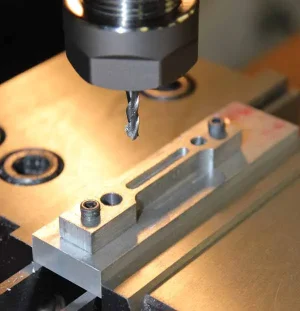

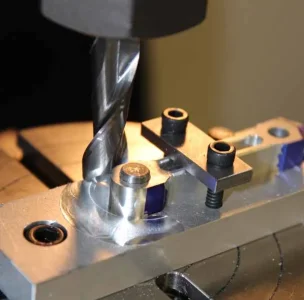

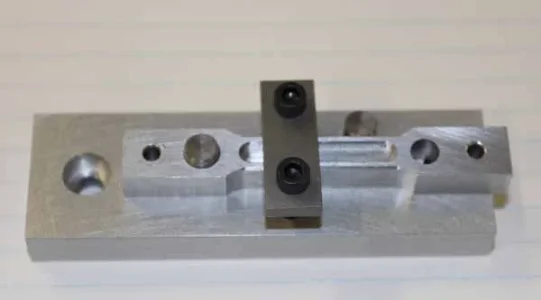

Some work-in-progress pics of my current project. It’s a 5-cylinder 4-stroke model radial engine, 24mm bore x 22mm stroke 50cc total displacement. Uses RC methanol based fuel & glow plug ignition. About 950-5500 rpm. I bought (2d-paper) plans from a builder in Germany. This is my first attempt at anything like this. But basically model engineering / engine building is my longstanding dream / justification for metalworking machines.

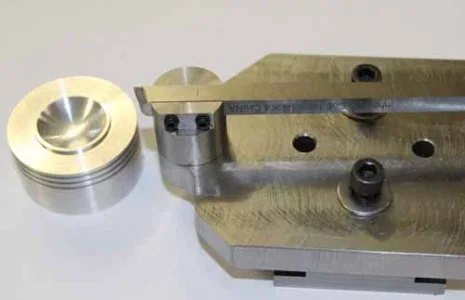

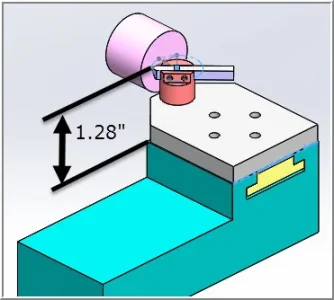

I set a goal to make one complete cylinder stack ‘prototype’ & the related jigs/fixtures. If that pans out without too many ulcers I'll proceed on remaining cylinder replication mode & then crankcase etc. A cylinder stack means cylinder barrel + liner + piston + head + valve cages + valves + springs+ rocker perch/arm/cover assembly, inlet/exhaust fittings…. Many engine builders prefer to start with the ‘big chunk’ (the crankcase) & work their way outwards. But I’ve also noticed 90% of issues are lurking in the fiddly bits, particularly valve seal. So I’m attacking it from the other end. Wish me luck.

I set a goal to make one complete cylinder stack ‘prototype’ & the related jigs/fixtures. If that pans out without too many ulcers I'll proceed on remaining cylinder replication mode & then crankcase etc. A cylinder stack means cylinder barrel + liner + piston + head + valve cages + valves + springs+ rocker perch/arm/cover assembly, inlet/exhaust fittings…. Many engine builders prefer to start with the ‘big chunk’ (the crankcase) & work their way outwards. But I’ve also noticed 90% of issues are lurking in the fiddly bits, particularly valve seal. So I’m attacking it from the other end. Wish me luck.

Attachments

Last edited: