-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pregraph Tool and Cutter Grinder, Victoria, $457

- Thread starter mickeyf

- Start date

Be aware, that is NOT a general purpose tool, the design is essentially aimed at people doing single lip engraving cutters for Pantograph machines.

Gonna take a LOT of Fiddle and Fail, to get more than the most basic of results, if you think it will do end mill sharpening.

Just saying.

Gonna take a LOT of Fiddle and Fail, to get more than the most basic of results, if you think it will do end mill sharpening.

Just saying.

mickeyf

Super User

Ah, good to know. Now I can be happy letting it pass! (Of course, I always wanted a pantogragh too...)Be aware, that is NOT a general purpose tool, the design is essentially aimed at people doing single lip engraving cutters for Pantograph machines.

Gonna take a LOT of Fiddle and Fail, to get more than the most basic of results, if you think it will do end mill sharpening.

Just saying.

Dan Dubeau

Ultra Member

You can do a lot on a single lip grinder, but it's true they were meant for that singular purpose. I used to use one daily to grind single lip engraving cutters, but did also find other uses for it such as d bit reamer grinding, and occasional bullnose grinding on endmills. I never did lathe toolbits, but they could be done with the right attachment (could be a fun shop project). They can also sharpen drills. Endmill flutes would be a stretch, but ends "can" be touched up. I say "can" in quotes, because while I've read that guys have done them, I've also read it can be fidly and not worth trying. I've never tried. They're basically just a precision spindle with a fine infeed rod, and variable fixturing, so if you're creative, you're only limited by your imagination as to what you might be able to sharpen on it. I know from my own limited experience with one that they're great for single lip cutters, and i'd find space for one if a good deal presented itself.

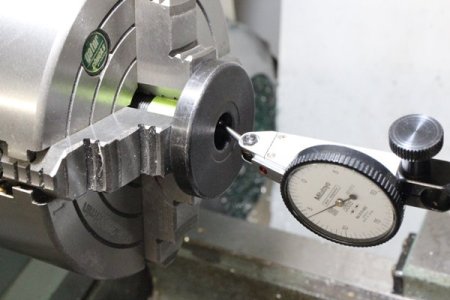

The one above is a taiwanese deckel clone, and IMO would be a much better starting point than a modern Chinese one from shars/accusize. Especially considering that one looks barely used, and comes with collets etc, But I wouldn't buy one expecting to shapen endmills.

The one above is a taiwanese deckel clone, and IMO would be a much better starting point than a modern Chinese one from shars/accusize. Especially considering that one looks barely used, and comes with collets etc, But I wouldn't buy one expecting to shapen endmills.

I had one of those; sold it when I got a real deal Deckel S0 and honestly features-wise the pregraph was better/ more modern (taper hub wheel hub, more graduations engraved...)

in my shop it's an invaluable tool for making weird shaped cutters (custom width slot mills, dovetail cutters, radius cutters etc, threading tools...) but if you don't do any of that sort of work then yeah I guess it's not super worthwhile.

in my shop it's an invaluable tool for making weird shaped cutters (custom width slot mills, dovetail cutters, radius cutters etc, threading tools...) but if you don't do any of that sort of work then yeah I guess it's not super worthwhile.

You could do some more searching on the interweb, but my hunch is it is one of the earlier/better clone attempts of Deckel SO. I would suspect Taiwan, but not 100%. They went for bigger bucks but probably still half the cost of a Deckel.

Judging by the picture, the collets are definitely of the format Deckel used. I think they were SO but I always get confused because the TCG's were always called U2 & seems like that get associated to the collets. Anyway, for a while it was hard/expensive to get them but I'm pretty sure now quite available on AliExpress. Back in the day, when it was really just principally known as a D-bit type cutter, they only had a handful of (metric) collets & because they matched common shanks to make custom cutters. Other accessories kind of got glommed (I think) when the clones started arriving. Glorified rectangular bit holders & some endmill/drill type sharpeners. Some of them useful, others less so. First they copied the U-collet for the work head, then subsequent models adapted to more current collets like R8 (Accusize) and 5C (Shars). On Ali you can still get U-collet headed machines.

Assuming the machine checks out (spindle play, motor, smooth motions...) you would need to be aware of its spindle nose taper. Maybe they copied Deckel or maybe they went their own way. Where this becomes important is you really want some matching hubs because they should stay put on the wheel once centered & dressed vs. only having one or a few & come off every wheel change & start all over again. You can for sure make them, but its work. Just saying, don't assume you can pick up from Shars because they may well be different & to this day I don't think Accusize carries them. My Accusize TCG has a different spindle taper than a Shars TCG. And (to be confirmed) I recently saw another Accusize CG that may be different again to mine. So many of the lower tier Chinese machines are a bit of cluster. Shars TCG is heads & tails better quality than Accusize. Its bigger & redesigned in many areas. I can go into a lot more detail but that's outside the scope of this used machine discussion.

Judging by the picture, the collets are definitely of the format Deckel used. I think they were SO but I always get confused because the TCG's were always called U2 & seems like that get associated to the collets. Anyway, for a while it was hard/expensive to get them but I'm pretty sure now quite available on AliExpress. Back in the day, when it was really just principally known as a D-bit type cutter, they only had a handful of (metric) collets & because they matched common shanks to make custom cutters. Other accessories kind of got glommed (I think) when the clones started arriving. Glorified rectangular bit holders & some endmill/drill type sharpeners. Some of them useful, others less so. First they copied the U-collet for the work head, then subsequent models adapted to more current collets like R8 (Accusize) and 5C (Shars). On Ali you can still get U-collet headed machines.

Assuming the machine checks out (spindle play, motor, smooth motions...) you would need to be aware of its spindle nose taper. Maybe they copied Deckel or maybe they went their own way. Where this becomes important is you really want some matching hubs because they should stay put on the wheel once centered & dressed vs. only having one or a few & come off every wheel change & start all over again. You can for sure make them, but its work. Just saying, don't assume you can pick up from Shars because they may well be different & to this day I don't think Accusize carries them. My Accusize TCG has a different spindle taper than a Shars TCG. And (to be confirmed) I recently saw another Accusize CG that may be different again to mine. So many of the lower tier Chinese machines are a bit of cluster. Shars TCG is heads & tails better quality than Accusize. Its bigger & redesigned in many areas. I can go into a lot more detail but that's outside the scope of this used machine discussion.

Thanks Peter, that's super helpful!You could do some more searching on the interweb, but my hunch is it is one of the earlier/better clone attempts of Deckel SO. I would suspect Taiwan, but not 100%. They went for bigger bucks but probably still half the cost of a Deckel.

Judging by the picture, the collets are definitely of the format Deckel used. I think they were SO but I always get confused because the TCG's were always called U2 & seems like that get associated to the collets. Anyway, for a while it was hard/expensive to get them but I'm pretty sure now quite available on AliExpress. Back in the day, when it was really just principally known as a D-bit type cutter, they only had a handful of (metric) collets & because they matched common shanks to make custom cutters. Other accessories kind of got glommed (I think) when the clones started arriving. Glorified rectangular bit holders & some endmill/drill type sharpeners. Some of them useful, others less so. First they copied the U-collet for the work head, then subsequent models adapted to more current collets like R8 (Accusize) and 5C (Shars). On Ali you can still get U-collet headed machines.

Assuming the machine checks out (spindle play, motor, smooth motions...) you would need to be aware of its spindle nose taper. Maybe they copied Deckel or maybe they went their own way. Where this becomes important is you really want some matching hubs because they should stay put on the wheel once centered & dressed vs. only having one or a few & come off every wheel change & start all over again. You can for sure make them, but its work. Just saying, don't assume you can pick up from Shars because they may well be different & to this day I don't think Accusize carries them. My Accusize TCG has a different spindle taper than a Shars TCG. And (to be confirmed) I recently saw another Accusize CG that may be different again to mine. So many of the lower tier Chinese machines are a bit of cluster. Shars TCG is heads & tails better quality than Accusize. Its bigger & redesigned in many areas. I can go into a lot more detail but that's outside the scope of this used machine discussion.

Agree, above. If it actually does fit your needs, it seems a hell of a deal!

My comments above were simply to draw attention to that it was NOT a plug and play solution to any old dull cutter!

They are not incapable, but you DO have to learn a fair few things about them, to make them do what you want.

Standard rules apply, you MUST be ten percent smarter than the machine you are running!

My comments above were simply to draw attention to that it was NOT a plug and play solution to any old dull cutter!

They are not incapable, but you DO have to learn a fair few things about them, to make them do what you want.

Standard rules apply, you MUST be ten percent smarter than the machine you are running!

You could do some more searching on the interweb, but my hunch is it is one of the earlier/better clone attempts of Deckel SO. I would suspect Taiwan, but not 100%. They went for bigger bucks but probably still half the cost of a Deckel...

I had this same model. it's a nicer old clone, pretty well featured and not super cheap. for example the knob handles are the type with the spring-loaded spline in them so you can pull them out and reorient the handle.

it takes the deckel 20mm collets (U2 or 355e, 20mm shank with s20x2 buttress thread) which you can get on ali (U2 collet) for not a ton of money.

I looked up getting other hubs for mine and shars has a similar option but if I recall it's not the same. mine had a Heinman machinery tag on it and they still show them on their website so maybe it's possible to get additional hubs from them. I forget if the hub matches the deckel one but it has a differential screw as well

The (very nicely made) Shars hubs link here. They come in 2 wheel hole ID flavors

www.shars.com

www.shars.com

Hubs are 1:5 taper ratio. So included angle = ArcTan (1/5) = 11.309 deg or 5.65 deg per side

My Accusize is 1:10 taper ratio. its undocumented so first taken by spindle measurements, then validated using arbors & blanks & blueing etc. Accusize does not stock hubs for their own machines even though I've had a conversation with them explaining why they are important to customers. As I subsequently began disassembling & rebuilding my machine & seeing so many other QC issues, maybe that's just as well.

Accusize = ArcTan(1/10) = 5.710 deg included angle = 2.855 deg per side

I only discovered this when the Shars hubs arrived & of course did not fit. But I was able to machine & lap them to suite my spindle.

I'm tagging @Don Sipes on this because same issue recently came up in discussion. My spindle housing was a real piece of work, I considered making a new one & spindle to match Shars taper, but in the end managed to salvage the housing. I'd have to check my notes on the bearing situation but it was good enough for me to carry on for now. I'll eventually do a writeup on my TCG, have a few more things to complete. But knowing what I know today, don't waste your money on this 'casting kit' unless its spit cheap & you want to do remedial work. I have a hunch most of the Ali/Ebay ones are pretty similar based articles & posts I've seen. The Shars (5C collet work head) model is a different machine & much closer to acceptable. Even so, that is the base model Renzetti & Gotteswinter did their own improvements to.

I have some Deckel manuals but no spindle dimensions. And as mentioned, I think some re-manufacturers may have cloned this aspect & others may have gone their own way.

appears as a tapered spindle nose

appears as non-tapered spindle nose. Older / original? Deckel?

Grinding Wheel Adapter for 3/4" Arbor Hole

Hubs are 1:5 taper ratio. So included angle = ArcTan (1/5) = 11.309 deg or 5.65 deg per side

My Accusize is 1:10 taper ratio. its undocumented so first taken by spindle measurements, then validated using arbors & blanks & blueing etc. Accusize does not stock hubs for their own machines even though I've had a conversation with them explaining why they are important to customers. As I subsequently began disassembling & rebuilding my machine & seeing so many other QC issues, maybe that's just as well.

Accusize = ArcTan(1/10) = 5.710 deg included angle = 2.855 deg per side

I only discovered this when the Shars hubs arrived & of course did not fit. But I was able to machine & lap them to suite my spindle.

I'm tagging @Don Sipes on this because same issue recently came up in discussion. My spindle housing was a real piece of work, I considered making a new one & spindle to match Shars taper, but in the end managed to salvage the housing. I'd have to check my notes on the bearing situation but it was good enough for me to carry on for now. I'll eventually do a writeup on my TCG, have a few more things to complete. But knowing what I know today, don't waste your money on this 'casting kit' unless its spit cheap & you want to do remedial work. I have a hunch most of the Ali/Ebay ones are pretty similar based articles & posts I've seen. The Shars (5C collet work head) model is a different machine & much closer to acceptable. Even so, that is the base model Renzetti & Gotteswinter did their own improvements to.

I have some Deckel manuals but no spindle dimensions. And as mentioned, I think some re-manufacturers may have cloned this aspect & others may have gone their own way.

appears as a tapered spindle nose

appears as non-tapered spindle nose. Older / original? Deckel?

Attachments

Dan Dubeau

Ultra Member

Atta Boy! Nice haul.

I’m super stoked!Atta Boy! Nice haul.

Dan Dubeau

Ultra Member

You should be. Nice machine, great price.

Now the learning begins!You should be. Nice machine, great price.