VFD wiring can be a dog's breakfast. There are only two ways to wire a VFD. The right way and any other way that works.

They are basically pretty forgiving devices with lots of built in self protection.

@Tomc938 - don't let the comments above from

@Dabbler &

@thestelster dissuade you from using a VFD. Both of them have fairly extensive experience and they are both right.

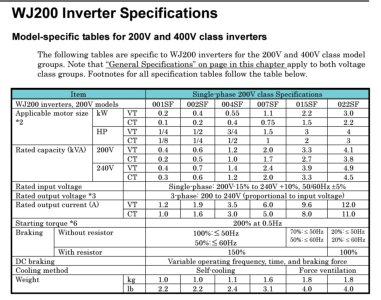

VFD's come in many flavours. The one you want (and the one I hope you ordered) should be a single phase 220V in and 220V 3ph out.

I "believe" that the Hitachi Application note that Stel referenced above is the advice that Hitachi gives for when a 3ph in and 3ph out VFD is used with just 1ph in. That seems like a strange configuration. But it really isn't. Three phase VFD's generally provide two design functions. 1. To convert 1ph to 3ph and 2. To provide variable frequency output to control motor speed. Not all VFD'S do both.

It isn't necessary to increase the current rating when using a VFD that is DESIGNED to work with 1ph input. HOWEVER, it will not do any harm if you do. And it's always good to err on the safe side.

Primarily because a mill motor needs to move around as the head configuration is changed, the motor wiring should be stranded. Stranded wire is more flexible. Single core wire could work harden over time and crack and/or short circuit. I say primarily because safety is always a primary concern. However, a VFD's output also has high frequency components in it that also benefit from using stranded wire. That's why speaker wire is always stranded. Although it is configurable, the VFD carrier frequency is almost always in the audio frequency spectrum - typically between 5khz and 20khz.

The wire Dabbler recommended will work just fine. However, it isn't the best wire. The best wire has four stranded wires in it that are individually shielded. It is specifically designed for use with a VFD. For very long wiring runs between the VFD and motor, shielded wire is definitely recommended and might even be required. However, it isn't critical for short wiring runs with the VFD located next to the machine. If you can find shielded cable, by all means use it (and tell me where you got it!). If not, stranded flexible unshielded cable will work. I have unshielded cable on my machine for now. I plan to upgrade to shielded wire when I can find some without paying a king's ransom for it. I'll also buy enough so I can share it with other members who might want some. 50ft would serve 5 of us! Don't hold your breath waiting for me though, just get the regular stranded wire from home depot or wherever and start using your mill.

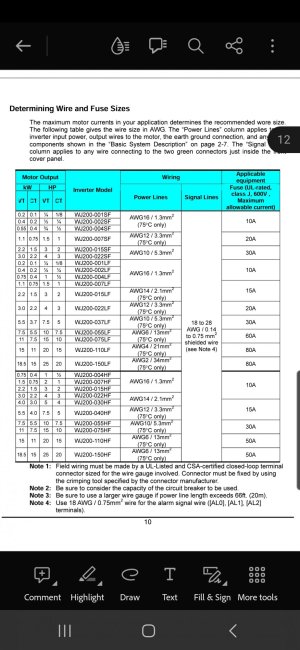

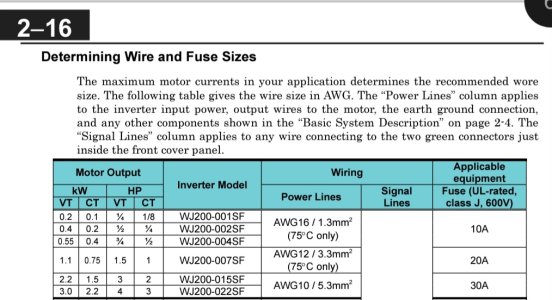

Regarding your original question about the wire gauge. 14 gauge wire is totally sufficient for your application with a 1.5 hp motor. 12 gauge wire would be better but isn't necessary. 8 gauge is totally unnecessary and gross overkill. Save that valuable 8 gauge wire for places where it is needed.

I hope that helps without getting more confusing.