This model has the 2 adjustments providing you get the indicator head as shown. I think this style comes in both mini mag base & next larger arm size up, but you'd have to confirm the catalog.

NOGA,NOGA DG6160 DBL FINE ADJUSTMENT MAG BASE,1-457-917,KBC Tools & Machinery

NOGA,NOGA DG6160 DBL FINE ADJUSTMENT MAG BASE,1-457-917,KBC Tools & Machinerywww.kbctools.ca

It is absolutely beautiful! Perfect!

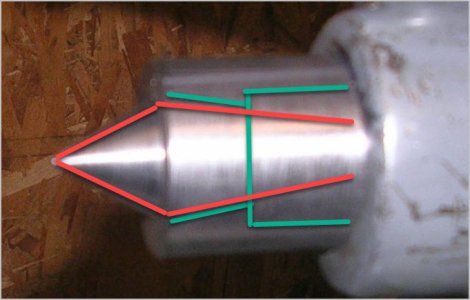

Is it my imagination or does that end have three different indicator mounts - two sizes of stubs and one dovetail?

Edit - KBCs website says it actually has 5 different mounts - 6mm, 8mm, 3/8", dovetail, and back lug.

Price is up there, but it really is perfect!

The Yeti is happy......!

Last edited: