Dabbler

ersatz engineer

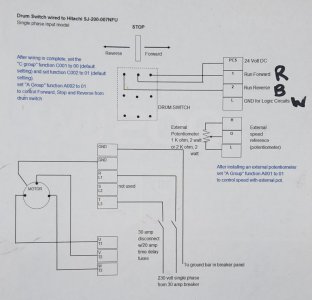

I hope it is the latter. You should not have any switches wired between the VFD and the motor. Voids Teco's warranty, etc.Is the drum switch switching the line out from the VFD, or just wired to the VFD's low voltage forward/reverse control?