Brian H

Super User

I have been waffling back and forth about spending time pondering the pros and cons between modifying my existing lathe and simply upgrading to a new lathe.

I have been using my MX-210v 8 x 16 lather for several years now and have spent many hours improving the many issues and have gotten it working quite nicely. Recently I entertained adding and electronic lead screw and power cross-feed unit. In preparation for this I was working at getting better tolerances/smoothness with the carriage and cross-feed. It has been a frustrating process, it seems as I improve in one area another appears.

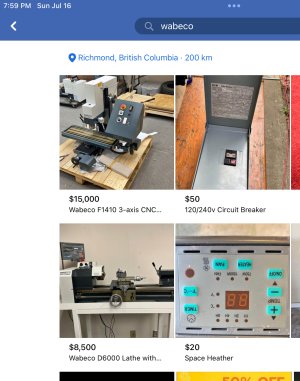

This is bringing me back to simply spending the money and getting a lathe with the options I would like to have. I spent quite a bit of time comparing Busy bee, craftex, grizzly and precision matthews. Although these are all similar lathes, I couldn't call the the same.

This brings me to my main question, is there a way to determine what quality/precision level the machine is built to as compared to what you have to pay? I know the lathe I purchased was very inexpensive (under $1500) and I did know I was getting a lower quality machine, but that is all that I could afford at the time, and I didn't know what features would be needed/wanted. I am in a position where I am prepared to pay a bit more to get the features I now would like to have in a lathe. The most challenging part of this is to fit it in the space I have available.

I'm not sure if a wish list of features would help with advice, but here are the things I'd like to have:

-ability to single point thread (left and right)

-power cross feed

-ability to adjust feed rate independantly of spindle speed

At this point I have narrowed my selection to two options., Precision Matthews PM-1130 or Grizzly G4003G. These are both very close in price point (nothing in stock at this time though)

I know there are many of you out there that have probably been in a very similar position and I would like this to be my "forever" lathe. So any advice or suggestions (there may be models I have missed comparing) would be greatly appreciated.

I have been using my MX-210v 8 x 16 lather for several years now and have spent many hours improving the many issues and have gotten it working quite nicely. Recently I entertained adding and electronic lead screw and power cross-feed unit. In preparation for this I was working at getting better tolerances/smoothness with the carriage and cross-feed. It has been a frustrating process, it seems as I improve in one area another appears.

This is bringing me back to simply spending the money and getting a lathe with the options I would like to have. I spent quite a bit of time comparing Busy bee, craftex, grizzly and precision matthews. Although these are all similar lathes, I couldn't call the the same.

This brings me to my main question, is there a way to determine what quality/precision level the machine is built to as compared to what you have to pay? I know the lathe I purchased was very inexpensive (under $1500) and I did know I was getting a lower quality machine, but that is all that I could afford at the time, and I didn't know what features would be needed/wanted. I am in a position where I am prepared to pay a bit more to get the features I now would like to have in a lathe. The most challenging part of this is to fit it in the space I have available.

I'm not sure if a wish list of features would help with advice, but here are the things I'd like to have:

-ability to single point thread (left and right)

-power cross feed

-ability to adjust feed rate independantly of spindle speed

At this point I have narrowed my selection to two options., Precision Matthews PM-1130 or Grizzly G4003G. These are both very close in price point (nothing in stock at this time though)

I know there are many of you out there that have probably been in a very similar position and I would like this to be my "forever" lathe. So any advice or suggestions (there may be models I have missed comparing) would be greatly appreciated.