I have been using them in both CCMT & DCMT formats for a few years now & so far pleased. I've posted a few pics in the past. I did the 303 stainless parts with them on my radial, including valves. Then I did some back to back tests on 4140, 1144-SP & also some sh*t grade 1018 which always looks a bit stringy regardless of cutter. For whatever reason, geometry, coating or combination, the SS inserts did a better job. Both AliExpress & Ebay sourced, I'd have to check.You should try some inserts for Stainless yourself. I'd love to hear and see your experiences too.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking for an insert

- Thread starter Gennady

- Start date

10mm is the max with my QCTP (0xA size) and the available distance between the top of the top slide and lathe centre.

I am still looking for you Craig.

Quick question, my BXA has a tall holder option that will take the standard 5/8 holders to 3/4. I don't suppose yours has a tall option that takes you from 3/8 to 1/2?

The problem is that the lathe centre is about 0.63 or 16mm above the top of the top slide. That means that with a 10mm tool shank there is only 6mm for the shelf of the tool holder under the tool shank + for a little height adjustment room is desirable. I could always mill a bit off the bottom of a 1/2-inch tool.

The problem is that the lathe centre is about 0.63 or 16mm above the top of the top slide.

Gotcha. Ya, that basically makes my question moot.

I did successfully machine the bottom off a 1" parting tool to make it 3/4" and it has worked quite well so far. I've even pushed it. But 3/4" is still double a 3/8 tool.

Nonetheless, what harm can it do to try? I did find some 1/2 tools that used the 1/4" inserts but they were in sets. So l'll try again to find a single.

@kstrauss - That did not take too long. Here is one on Ali for 10 bucks and comes with 10 inserts! Looks quite similar to the one in my set. Shipping is more than the product at 13.50 but still....

10PCS carbide inserts WCMX050308 and 1PC SWGCR1010E05

a.aliexpress.com

a.aliexpress.com

10PCS carbide inserts WCMX050308 and 1PC SWGCR1010E05

10PCS carbide inserts WCMX050308 and 1PC SWGCR1010E05 S-type turning tool - AliExpress 1420

Smarter Shopping, Better Living! Aliexpress.com

Thanks! I'd love to try one at a reasonable price.Gotcha. Ya, that basically makes my question moot.

I did successfully machine the bottom off a 1" parting tool to make it 3/4" and it has worked quite well so far. I've even pushed it. But 3/4" is still double a 3/8 tool.

Nonetheless, what harm can it do to try? I did find some 1/2 tools that used the 1/4" inserts but they were in sets. So l'll try again to find a single.

@kstrauss - that link is just the first one that looked like a good deal to me. You might want to shop around a bit more for an SWGCR1010 tool and WCMX inserts. That's the trigon in the smaller one-sided 1/4" IC inserts. You might be able to find free shipping too. I know you can also get inserts for SS, aluminium, Cast Iron, etc too.

@kstrauss - my own 1/2" holder is from a 1/2" kit I got from grizzly 15 years ago (T23906). It is a SWGCR - 1/2. It takes WCMT050304 or WCMT534 inserts which are available for steel, aluminium, cast-iron, stainless, and maybe others...

W - Trigon

C - 7 Degree edge

M - tolerance

T - Countersunk Screw Hole

05 - 5/16 Inscribed circle

(note - not 1/4 as said before)

03 - 1/8 inch Thick

04 - 1/64 corner

(note - other tips R available)

W - Trigon

C - 7 Degree edge

M - tolerance

T - Countersunk Screw Hole

05 - 5/16 Inscribed circle

(note - not 1/4 as said before)

03 - 1/8 inch Thick

04 - 1/64 corner

(note - other tips R available)

MrWhoopee

Well-Known Member

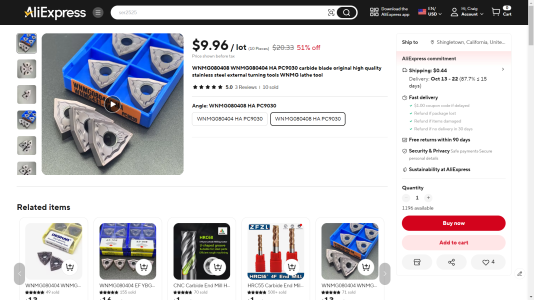

Here is that same insert (same picture even) on AliexpressThey just arrived this morning. Yup, they are definitely sharp. So that clearly supports what has been said.

Unfortunately, they didn't come with feed and speed recommendations so I'll have to see what I can find we elsewhere and them mark that on the insert package.

These are WNMG 080404 and 08 with a PC9030 coating for SSteel.If anyone has speed and feed info for inserts like this, I'd appreciate it.

I'll also ask the seller but I'm not exactly optimistic that they will know.

Scratch that - the info isn't on the insert box, but it is posted on the sellers page.

Ap = 0.1 (0.004 - 0.197)"

Fn = 0.008 (0.001 - 0.160)"/r

Vc = 492 (328-556) sfm

The above is the same for both tip sizes which seems a bit odd to me, especially the feed rate but then again it is from China.

The recommended speeds N feeds support what you guys said earlier.

Going to have fun trying these out on some fine cuts!

Constantly learning. Lovin it!

Edit - offline I was asked for a link. My bad.

Here it is:

WNMG Carbide Insert for Stainless Steel(WNMG080404 HA PC9030) https://a.co/d/hTp2mSq

trlvn

Ultra Member

I got some CCMT and VCMT tooling for my lathe. @gerritv was kind enough to offer a visit to his shop where he walked me through the tooling he uses regularly. He posted a link to the AliExpress store he uses and I basically replicated his order.@trlvn - did you end up ordering anything? Need any more info?

So far, the inserts are working fine. Since they can run at > 3X the rpm compared to HSS, it speeds up roughing out a part!

That said, I still use HSS. For example, I needed to put a short threaded end--#5-40--on some 1/4" steel rods. I wanted to use Joe Pie's approach where you take the stock right to finished diameter in one cut to avoid having the work bend or flex. So I touched up the edge on a HSS tool and took a 0.063" cut (0.125 diameter reduction). Worked perfectly the 10 or so times I've done it so far. I should give it a try with the CCMT insert but it is working with the HSS so I don't have a that much motivation.

At least I have a foot in both camps now...

Craig

What is this store ? can you share link to it, please ?He posted a link to the AliExpress store he uses and I basically replicated his order.

trlvn

Ultra Member

DotStripe:What is this store ? can you share link to it, please ?

Craig

I got some CCMT and VCMT tooling for my lathe.

I see. I had thought you wanted to try the Trigon insert shape. I personally think its slightly better for my kind of work but only marginally so.

I agree with your approach to maintaining a relationship with HSS. It will be a -40 day in July on the equator when I stop using HSS. While I have embraced Carbide Insert Tooling in my shop, it isn't the only game in town. I also continue to advocate in favour of HSS to new machining hobbiests. I believe it teaches us things about the cutting process that we won't learn if we dive right into Carbide.

trlvn

Ultra Member

@Susquatch I was very frustrated trying to understand the endless varieties of inserts and eventually decided to just duplicate a setup that seemed to be working for someone else with a similar size lathe.

Re HSS and grinding, I was (and still am) interested in hand woodworking tools including wood carving and wood turning. Through that, I got a bit of experience sharpening different kinds of tools including some complex shapes. So shaping and sharpening HSS lathe bits wasn't a big stretch for me. I could see where some people would like to avoid having to learn another topic.

Re DotStripe, I should add that, as others have said, patience is required when buying from AliExpress. There was an initial flood of messages after I placed the (first) order but it was about 6 weeks before the shipments (plural: my 6 line items came in 2 separate packages) arrived at my door. The provided tracking was essentially useless. It was after that I realized that I ordered a left-hand tool holder for the VCMT inserts by mistake. Another 5 or 6 weeks passed before I got the right-hand version that I wanted all along. Not quite the instant gratification we've become accustomed to.

But, I agree with @gerritv that these are brand-name inserts: the packaging on mine say "Mitsubishi Materials" and "Made in Japan". The DotString store does NOT say this. The product detail page say "Origin: Mainland China" with no indication of the manufacturer. I believe these are likely production overruns or something similar. Or perhaps the particular coating was changed and these are "obsolete" products being remaindered. The bottom line is that the price is incredible (currently C$4.31 for 10 inserts!!) and they work well for me.

Craig

Re HSS and grinding, I was (and still am) interested in hand woodworking tools including wood carving and wood turning. Through that, I got a bit of experience sharpening different kinds of tools including some complex shapes. So shaping and sharpening HSS lathe bits wasn't a big stretch for me. I could see where some people would like to avoid having to learn another topic.

Re DotStripe, I should add that, as others have said, patience is required when buying from AliExpress. There was an initial flood of messages after I placed the (first) order but it was about 6 weeks before the shipments (plural: my 6 line items came in 2 separate packages) arrived at my door. The provided tracking was essentially useless. It was after that I realized that I ordered a left-hand tool holder for the VCMT inserts by mistake. Another 5 or 6 weeks passed before I got the right-hand version that I wanted all along. Not quite the instant gratification we've become accustomed to.

But, I agree with @gerritv that these are brand-name inserts: the packaging on mine say "Mitsubishi Materials" and "Made in Japan". The DotString store does NOT say this. The product detail page say "Origin: Mainland China" with no indication of the manufacturer. I believe these are likely production overruns or something similar. Or perhaps the particular coating was changed and these are "obsolete" products being remaindered. The bottom line is that the price is incredible (currently C$4.31 for 10 inserts!!) and they work well for me.

Craig

Megar arc 5040dd

Super User

Your timing on this couldn't be better. Ordering ccmt inserts was on my to do list for this weekend.@Susquatch I was very frustrated trying to understand the endless varieties of inserts and eventually decided to just duplicate a setup that seemed to be working for someone else with a similar size lathe.

Re HSS and grinding, I was (and still am) interested in hand woodworking tools including wood carving and wood turning. Through that, I got a bit of experience sharpening different kinds of tools including some complex shapes. So shaping and sharpening HSS lathe bits wasn't a big stretch for me. I could see where some people would like to avoid having to learn another topic.

Re DotStripe, I should add that, as others have said, patience is required when buying from AliExpress. There was an initial flood of messages after I placed the (first) order but it was about 6 weeks before the shipments (plural: my 6 line items came in 2 separate packages) arrived at my door. The provided tracking was essentially useless. It was after that I realized that I ordered a left-hand tool holder for the VCMT inserts by mistake. Another 5 or 6 weeks passed before I got the right-hand version that I wanted all along. Not quite the instant gratification we've become accustomed to.

But, I agree with @gerritv that these are brand-name inserts: the packaging on mine say "Mitsubishi Materials" and "Made in Japan". The DotString store does NOT say this. The product detail page say "Origin: Mainland China" with no indication of the manufacturer. I believe these are likely production overruns or something similar. Or perhaps the particular coating was changed and these are "obsolete" products being remaindered. The bottom line is that the price is incredible (currently C$4.31 for 10 inserts!!) and they work well for me.

Craig

@Susquatch I was very frustrated trying to understand the endless varieties of inserts and eventually decided to just duplicate a setup that seemed to be working for someone else with a similar size lathe.

I understand. Trust me, I understand! I didnt follow anyone else's path, but in hindsight I prolly should have as it would have saved me a lot of flopping around like a dying fish on land. On the flip side, I believe I have a much better understanding now.

I basically confused your question with one asked by @kstrauss asking about Trigon inserts. I had thought you already had Carbide inserts and were interested in exploring Trigon.

It's all ok. I hope both of you are happy in your own pursuits and I apologize for being so easily confused. Getting old sucks but the opposite is far worse.