-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking at new lathe -- Opinions and Options

- Thread starter kevin.decelles

- Start date

The manual (hahaha) that came with the Modern Tool machine is a little 'lacking' for detail, and doesn't identify the type(s) of oils to use in the headstock etc.

I was browsing the Precision Matthews site and looked at the manual for the PM-1440E-LB lathe and was pleasantly surprised to find out it is essentially the same machine -- as in identical. I went through the part schematics, all the diagrams are identical, all the part numbers identical etc. The difference is that the PM manual is 50 pages and extremely detailed. Thank-you PM.

As a note, when you factor in shipping (to the border) and exchange, the machine was the same price as Modern. Food for though on anyone who was on the fence like I was re: importing a machine.

PM-14040E-LB = Modern Tool C0636A

I was browsing the Precision Matthews site and looked at the manual for the PM-1440E-LB lathe and was pleasantly surprised to find out it is essentially the same machine -- as in identical. I went through the part schematics, all the diagrams are identical, all the part numbers identical etc. The difference is that the PM manual is 50 pages and extremely detailed. Thank-you PM.

As a note, when you factor in shipping (to the border) and exchange, the machine was the same price as Modern. Food for though on anyone who was on the fence like I was re: importing a machine.

PM-14040E-LB = Modern Tool C0636A

Tom Kitta

Ultra Member

I was under impression most manual lathes should use type 32 oil in the main gear box and something a bit heavier in say threading gearbox / saddle gearbox. Reason for 32 hydraulic oil was that it doesn't create too much resistance during cold starts. They just had a pile of 32 at princess auto for like $45. Its few times more than needed for a 14x40 lathe.

Dabbler

ersatz engineer

For industrial lathes it is very common to not include all the information, such as oil choices. I've run into this a lot. The excuse is that oil gets better with time as the technology changes - you are expected to go to your lube dealer and buy the best for your described application. I used to care that I get the 'perfect' oil, now I'm of he opinion 'any lube is better than no lube' - so I use medium weight gear oil in gear boxes, etc. Some common sense apples. Way oil is kinda special, you can use 10W30 motor oil for a while, but it just doesn't stick to the ways the same, so I bought 5 gallons of SAE 68 way oil to ensure I have a supply (I couldn't find less!)

PM does such a complete job b/c they intend to sell to hobbyists, who prefer the information!

One very common mistake I've found is using transmission oil in gear boxes - then the seals get eroded and they leak. Transmission oil should never be used in gear boxes.

PM does such a complete job b/c they intend to sell to hobbyists, who prefer the information!

One very common mistake I've found is using transmission oil in gear boxes - then the seals get eroded and they leak. Transmission oil should never be used in gear boxes.

KBC sells different weight flavors of EEZ way oil in 1 gal qty for ~26$ Dabbler. Some buddies could probably split that because it goes a long ways. Get it, 'ways' Haha

That's a great idea! Look in the questions thread!

I bought 5 gallons of way oil from kbc last year to test their shipping policy. 50lbs shipped for 8 bucks flat rate -- true to their word

It's was the eez oil at sae 30 viscosity -- I like it fine

As u said, life time supply !

Sent from my iPhone using Tapatalk

It's was the eez oil at sae 30 viscosity -- I like it fine

As u said, life time supply !

Sent from my iPhone using Tapatalk

Dabbler

ersatz engineer

It is not just the weight, but 68 is not gong anywhere fast. I'm sure it will be fine. What makes it 'way' oil is the additive that make it sticky; (yes, they call them 'stiction' additives!)

68 is just the right weght. |I'd use the 68 in a heartbeat, it's just that you use a little more because it oozes off quicker than 68 Tonna will.

68 is just the right weght. |I'd use the 68 in a heartbeat, it's just that you use a little more because it oozes off quicker than 68 Tonna will.

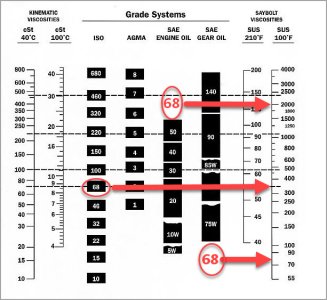

SAE 68 or ISO 68?

I think I bought SAE-20 way oil, I should go check. It makes things run nice & smooth & hangs around for a while. I also use it on vise slides, lead screws, all the lathe oiler nipples that lead to sliding parts. Maybe I'd go one higher like 30, after that I wonder if its getting too sticky? Maybe Alex knows but I think the CNC guys also want anti-wash-off properties with the fluids squirting away & machines running all day long & possibly that's why extra viscous is offered? I've never tried anything else so I really don't know.

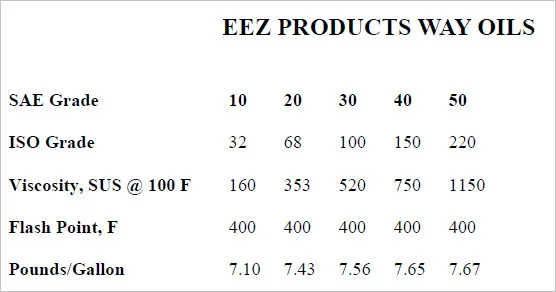

The thing about SAE scale 10,20,30...50, it seems like linear progression. But the viscosity is increasing exponentially. Here are the EEZ specs KBC sells. http://www.mullenoil.com/images/Lit-EEZ-WayOil.pdf

The units are SUS (Saybolt Universal Seconds). Its easy to visualize practically. If SAE20 oil flows through a defined orifice in 353 seconds, the same volume of SAE 50 takes 1150 seconds. And these viscosity are referenced at 100F (38C). At typical ~15C room temp, they will all be higher yet.

handy dandy chart

http://www.doolittleoil.com/faq/viscosity-sae-iso-or-agma

I think I bought SAE-20 way oil, I should go check. It makes things run nice & smooth & hangs around for a while. I also use it on vise slides, lead screws, all the lathe oiler nipples that lead to sliding parts. Maybe I'd go one higher like 30, after that I wonder if its getting too sticky? Maybe Alex knows but I think the CNC guys also want anti-wash-off properties with the fluids squirting away & machines running all day long & possibly that's why extra viscous is offered? I've never tried anything else so I really don't know.

The thing about SAE scale 10,20,30...50, it seems like linear progression. But the viscosity is increasing exponentially. Here are the EEZ specs KBC sells. http://www.mullenoil.com/images/Lit-EEZ-WayOil.pdf

The units are SUS (Saybolt Universal Seconds). Its easy to visualize practically. If SAE20 oil flows through a defined orifice in 353 seconds, the same volume of SAE 50 takes 1150 seconds. And these viscosity are referenced at 100F (38C). At typical ~15C room temp, they will all be higher yet.

handy dandy chart

http://www.doolittleoil.com/faq/viscosity-sae-iso-or-agma