If your wheels don't have ID markings then its kind of like a mystery gear, you'll have to measure OD & count teeth. The potential problem is where did the wheel come from? Maybe its a 15mm wheel from Asia/Europe, not a 5/8" wheel from N-Am.

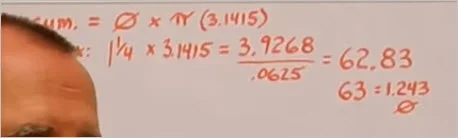

Joe has some good information & a ton of machining experience. But I had to watch his math explanation a few times. I'm a bit confused. I think he is saying:

- calculate the nominal part circumference C = Dia * Pi C = 1.25 in * 3.14159 = 3.927 in

- calculate equivalent number teeth N = C / circumference N = 3.927 * 16 TPI (same as 1/16=0.0625) N = 62.83

- N is not a round number because of the 0.83 remainder, so the knurl wheels wont track the shaft OD, we all agree

Around here I lose the scent. His whiteboard says a reduced diameter of 1.243 inch yields an even 63 teeth? But plugging those numbers into his same formula gets...

C = Dia * Pi C = 1.243 in * 3.14159 = 3.905 in

N = C / circumference N = 3.905 * 16 TPI = 62.479 teeth So we still have a remainder problem, this time 0.47. Its smaller but still not a round number

I looked in the comments & nobody mentioned this. Am I missing something here? Maybe he slipped a digit. He mentions 7 thou?

He could have just rearranged the formula a bit & calculated directly: Dia = N / (P * pi)

if N = 62, resultant Dia = 1.233 in (this is the best way because it calculates closest shaft diameter under nominal)

if N = 63, resultant Dia = 1.253 in (it works but note is bigger diameter than original nominal shaft size)

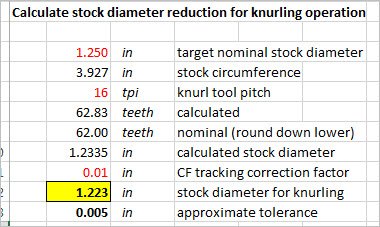

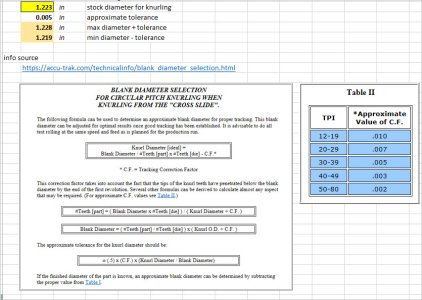

I used this link to make a little spreadsheet. They mention other correction factors over & above this pitch calculation. They also quantify a +/- tolerance which is (IMO) why sometimes knurling appears to work better than other times.

https://accu-trak.com/technicalinfo/blank_diameter_selection.html