A few years ago I stalled on this project.

The problem I ran into is the random width (including shrinkage over time) of the post.

So screwing into the post from both sides doesn't really clamp onto the post and it can droop downwards.

One option is to make one side tapered and insert a wedge that is pressed in with the plate on the back. However over time shrinkage or expansion in dry/wet weather can still cause problems.

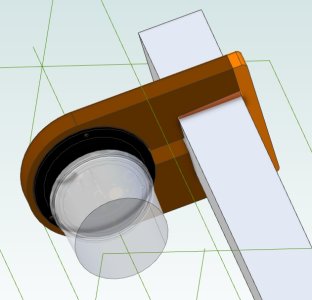

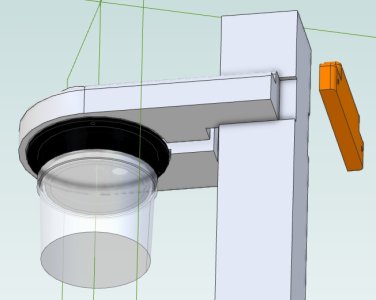

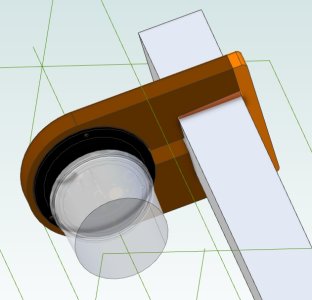

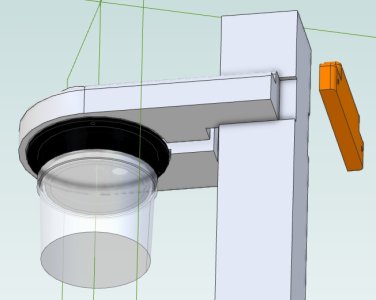

The other idea I had was to cut a couple of deep slots into the post and make the lamp holder narrower. Now it slides into the slot. If the ears of the holder are just a tad short then the orange clamp will pulled the holder in against the post keeping everything tight.

The slot under the holder is for the wires that run into the post and then down to the network connection with the other lights.

Here's the lamp running a preprogrammed sequence.

Suggestions for a better mounting method?

The problem I ran into is the random width (including shrinkage over time) of the post.

So screwing into the post from both sides doesn't really clamp onto the post and it can droop downwards.

One option is to make one side tapered and insert a wedge that is pressed in with the plate on the back. However over time shrinkage or expansion in dry/wet weather can still cause problems.

The other idea I had was to cut a couple of deep slots into the post and make the lamp holder narrower. Now it slides into the slot. If the ears of the holder are just a tad short then the orange clamp will pulled the holder in against the post keeping everything tight.

The slot under the holder is for the wires that run into the post and then down to the network connection with the other lights.

Here's the lamp running a preprogrammed sequence.

Suggestions for a better mounting method?