Hi All,

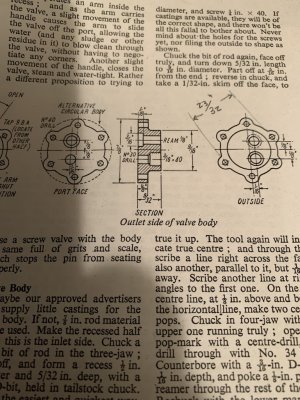

Next is the machining of the steam and shutoff handle passages in the two front half body halves.

It is a lot of setup work as the body halves have different features on each side where one has to reverse the part and then pick up a previously drilled through hole to complete the operation.

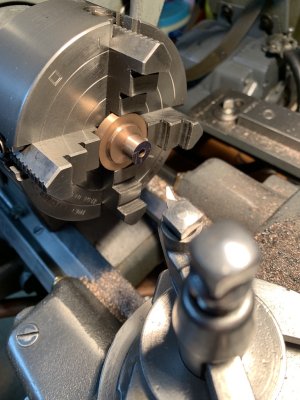

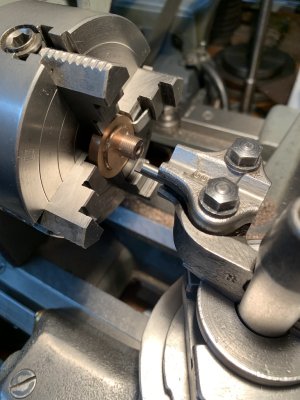

The parts have to be setup eccentrically as before in the 4 jaw on the two offset centres. The was done with the "wiggler" as seen previously. Then centre drill, drill undersize, counterbore a 3/16" diameter recess and finish with a 1/8" reamer all the way through for the shutoff lever passage. No matter how you proceed, it is a lot of chucking on the half body flange. As seen in the fourth photo, the half body flange is starting to show a lot of jaw marks from the tightening of the jaws. Here I should have added something earlier but I didn't.

To compensate for the above condition, the flange OD of both body halves was left 0.01" oversize as I knew this would likely happen. The last operation on these body halves is to drill and tap the six through bolt holes and then scallop the metal in between. This will effectively reduce the final OD of the valves and eliminate the jaw marks. Another lesson learned from the school of hard knocks when any softer material is chucked and you want the finished product (including the chucked sections) to be free of any evidence of machining. Also, these pressure marks will "swage" the surrounding metal (like the rear/front flange faces which I use as the square setting face on the chuck body) so they have to be monitored and if present, carefully stoned away before I mount the part in the chuck.

So, each passage requires a separate eccentric setup and then, after that, the half valve body needs to be reversed and the one drilled passage (not the reamed one) picked up as seen in the third photo. Fortunately, the drill makes a tight fit in bronze so I could re-centre it to better than 0.001" Again, this involves a lot of jaw loosening and tightening, so be aware that you are marking the work every time you do this and also make certain everything is bedded square.

One thing I did change was the LBSC article says thread 3/16"- 40 ME (model engineer) 1/8" deep as seen in the fourth photo. I made this thread 3/16"+ deep as even my ME bottoming tap has a 1/16" lead in which would only give a 1/16" full thread depth engagement! These ME threads are very fine threads to begin with and are not the strongest (if you want a stronger thread you need a coarser pitch thread - i.e. 32 TPI minimum) so having only a 1/16" full engagement was a no go. Even with a 1/8" full engagement one will have to be careful. This is another reason why I think LBSC never actually made these valves as this should have become obvious.

The last photo just shows all of the cutting tools needed just to do these "simple" steps. The wooden dowel was used, in conjunction with a small soft faced hammer, to gently tap the half body to ensure it was bedded square on the 4 jaw front face, the sharpie pen was used to mark which hole (and side) has the recess and which hole (and side) is threaded as it is easy to mix both passages up, the small triangular piece of relatively coarse broken oil stone was used to remove any and all face burrs left by machining and the 1/4" dia. aluminum rod with the 3/16" step on the end was used to check the recess depth.

PS: once your oil stone is "smeared" after stoning any soft metal, the only effective way of cleaning it again is with an ultrasonic cleaner, anything mechanical like using a file card really won't work so save up all of your broken bits and pieces and find someone who is willing and able and has the equipment... it never ends...