Dan Dubeau

Ultra Member

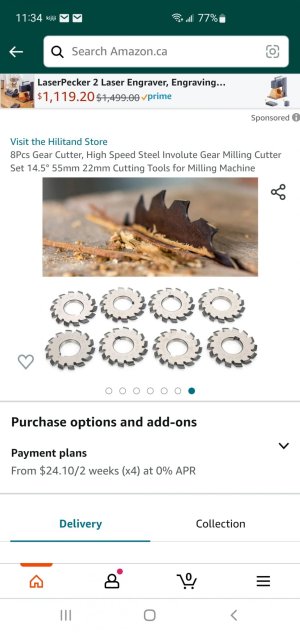

Anybody here use them? I'm starting to gather what I need to build my first model engine this winter, and the thought of buying a set of these gear cutters is tempting, but if I'm just going to light $100 on fire I'd rather not do that. I have read Ivan Laws book on gear cutting, have thought about building a eureka machine to cut my own tooling using the button method also, purely for the exercise in tool building as I think it would be a fun project but the practical side of me says just buy the damn cutters and get on with it, and stop all the side quests......

https://www.amazon.ca/Involute-Mill...mzn1.fos.71722c10-739d-471b-befb-3e4b9bf7d0d6

https://www.amazon.ca/8PCS-Milling-...mzn1.fos.71722c10-739d-471b-befb-3e4b9bf7d0d6

I'm pretty familiar with Chinese tooling standards, and have rolled the dice for many things in my home shop (and at work) pretty successfully quite a few times now, but am leery about these for some reason. Are my fears unfounded?

It would also be nice to cut the gears required for metric threading on my Myford which I think it 14.5 Pa like the first link? I can't remember off hand right now.

https://www.amazon.ca/Involute-Mill...mzn1.fos.71722c10-739d-471b-befb-3e4b9bf7d0d6

https://www.amazon.ca/8PCS-Milling-...mzn1.fos.71722c10-739d-471b-befb-3e4b9bf7d0d6

I'm pretty familiar with Chinese tooling standards, and have rolled the dice for many things in my home shop (and at work) pretty successfully quite a few times now, but am leery about these for some reason. Are my fears unfounded?

It would also be nice to cut the gears required for metric threading on my Myford which I think it 14.5 Pa like the first link? I can't remember off hand right now.