slow-poke

Ultra Member

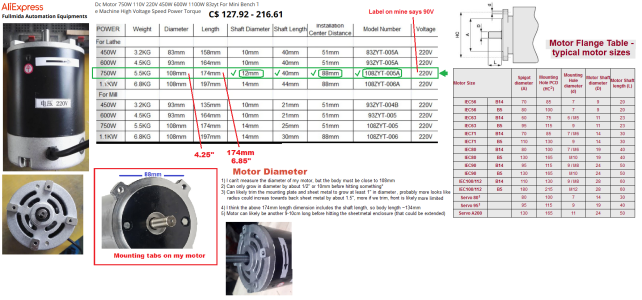

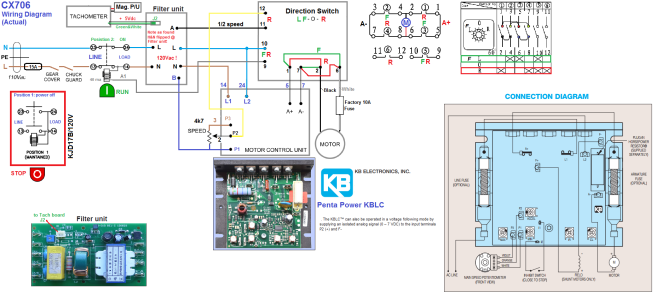

The original motor in my CX706 was a 750 W brushed DC motor powered by KBIC type motor controller. I replaced the original motor with a brushless style.I guess the other thing is that I don't really know the details of the motor in CX-706. I would have to disassemble a bunch of stuff to get a look at it.

My understanding is that it is a "1 HP" DC motor, aka 750 watts. (Brushed? Brushless?) I've learned a bit about AC motors but my most extensive experience with DC motors was with a race car set when I was 12! Not helpful! AIUI, the Craftex, PrecisionMatthews, King, etc 10X22 variable speed lathes are all pretty much alike. What powers them?

Craig