I see the Briggs & Stratton “Vanguard“ motors are in the Argos as well.

Argos have been around for decades.

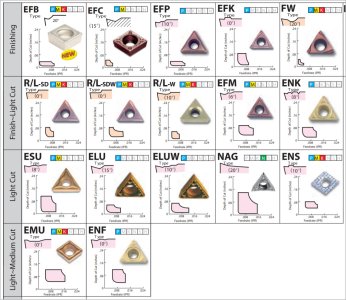

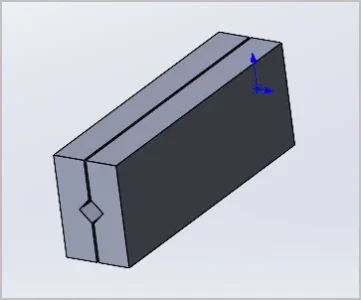

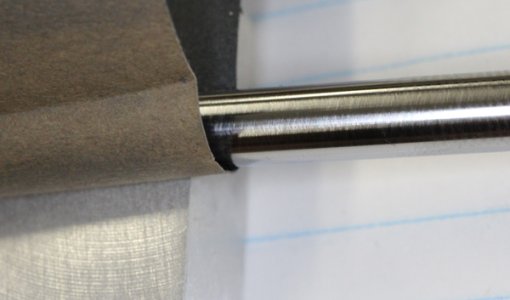

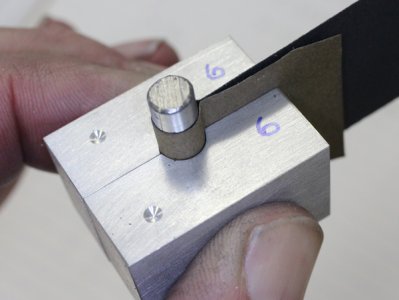

When you are machining the hubs . . . you can be successful with HSS or Carbide.

Just keep in mind that HSS may require grinding to maintain a sharp edge.

The carbide will hog out much more and at higher SFPM without exhibiting any wear. The only thing to watch out for is subjecting the carbide insert to shock loads.

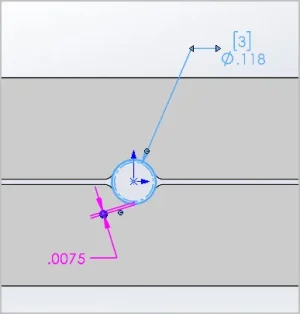

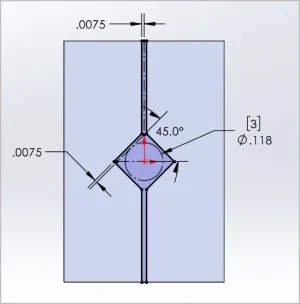

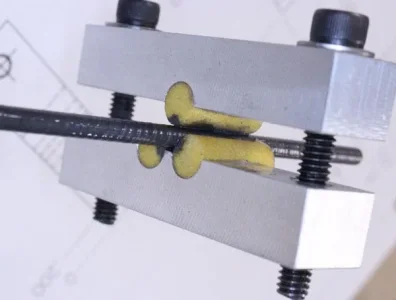

Make sure the tool and the workpiece are securely supported and reduce any chatter that may occur.

Take your time and get comfortable with your equipment and tooling.

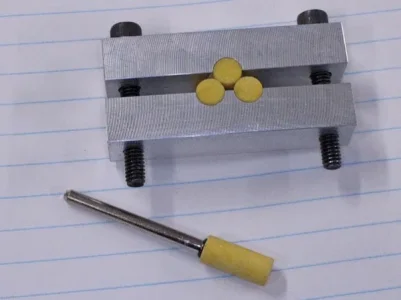

Use the NET to research recommendations for specific bearing setups and preloads.

Questions are inexpensive, mistakes cost you money.

Argos have been around for decades.

When you are machining the hubs . . . you can be successful with HSS or Carbide.

Just keep in mind that HSS may require grinding to maintain a sharp edge.

The carbide will hog out much more and at higher SFPM without exhibiting any wear. The only thing to watch out for is subjecting the carbide insert to shock loads.

Make sure the tool and the workpiece are securely supported and reduce any chatter that may occur.

Take your time and get comfortable with your equipment and tooling.

Use the NET to research recommendations for specific bearing setups and preloads.

Questions are inexpensive, mistakes cost you money.