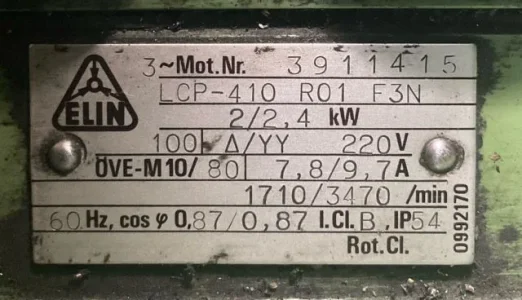

Fortunately, mine was a 208-230v motor to begin with. So an off the shelf teco l510 vfd made it easy.

If you could find a vfd which will take 240v, single phase in, and output 440-480v three phase, that would be super easy, and i can help you with the controls. Its very easy. I've never seen such a vfd, but they probably exist.

If you could find a vfd which will take 240v, single phase in, and output 440-480v three phase, that would be super easy, and i can help you with the controls. Its very easy. I've never seen such a vfd, but they probably exist.