-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DRO Mounting System

- Thread starter Susquatch

- Start date

Wow. Just wow. Powder coated, polished ground surface under a tenth, all for less than a hundred bucks.....

Dunno what to say. I'm definitely VERY impressed.

Another silly question - is the powder coating electrostatic? In other words, how well does it penetrate into the venting cavities?

This doesn't matter for my purposes, but now I am curious. I think a powder coated vented Rotor like that would cost 300 bucks from most auto companies and prolly 500 from an aftermarket specialty manufacturer. How the heck does KIA do that?

Dunno what to say. I'm definitely VERY impressed.

Another silly question - is the powder coating electrostatic? In other words, how well does it penetrate into the venting cavities?

This doesn't matter for my purposes, but now I am curious. I think a powder coated vented Rotor like that would cost 300 bucks from most auto companies and prolly 500 from an aftermarket specialty manufacturer. How the heck does KIA do that?

That arm used to hold the CNC control. It does use the lifting eye bolt hole.

Mine came with an arm so don't sweat it till you see what they send...

Well here it is. I kept it simple as possible for now. I made a 5/8-11 adapter to fit the lifteye hole in the top of the ram, and then drilled and tapped that to take the factory 8mm bolt and arm. Didn't like it, too floppy mopsy due to poor fit in the arm to the 8mm bolt, so I re-drilled and tapped for a standard 3/8-16 bolt and drilled the arm for a close fit to the 3/8 bolt shaft and recessed the adapter so the 3/8 bolt shaft was below the top of the adapter. WAY BETTER.

I'll prolly keep it like that till I see what @dfloen comes up with using an aluminium control arm. Right now, I just want it working and this was fast and easy and the perfect location.

Btw, it doesn't look level in the photo but it is. Very Happy for now.

Thanks to all who volunteered info and advice.

Nice!

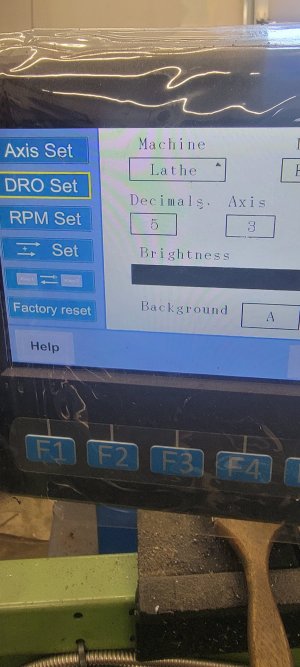

Does this DRO sum Z and U? That would be ideal to get the combined quill and knee movement.

Yup! It will add any two axis!

It will also interpolate so it can be used on a compound set at an angle. This one is for my mill so I won't be using it on my lathe, but it's nice to know it can do that. I don't know what the range is yet.

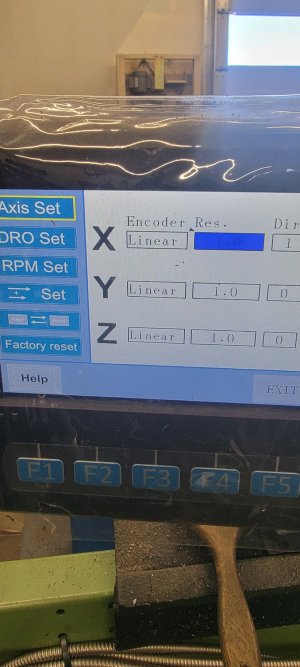

I got the 1 micron scales and just checked to confirm that they are indeed 1 micron. Now I need to figure out how to damp out the readings to eliminate the jitter.

Edit - I can't find it! Might have to live with a squirrel on caffeine.....

There is a vibration damping feature but all i want to do is tell it how many digits to display.

Edit - I can't find it! Might have to live with a squirrel on caffeine.....

There is a vibration damping feature but all i want to do is tell it how many digits to display.

Last edited:

DPittman

Ultra Member

I purposely got the 5 micron scales to avoid the constant flickering of the reading of an accuracy that I wasn't likely able to attain anyhow.I got the 1 micron scales and just checked to confirm that they are indeed 1 micron. Now I need to figure out how to damp out the readings to eliminate the jitter.

Edit - I can't find it! Might have to live with a squirrel on caffeine.....

There is a vibration damping feature but all i want to do is tell it how many digits to display.

A little black electricians tape should do the trickI got the 1 micron scales and just checked to confirm that they are indeed 1 micron. Now I need to figure out how to damp out the readings to eliminate the jitter.

Edit - I can't find it! Might have to live with a squirrel on caffeine.....

There is a vibration damping feature but all i want to do is tell it how many digits to display.

DPittman

Ultra Member

Yup and that trick works great too for the service engine light in you vehicle.A little black electricians tape should do the trick

The 'Money Light' . My bread and butterYup and that trick works great too for the service engine light in you vehicle.

Haha, I sorta did that for my track car for ABS, VDC, Seat belt, and a couple other warning lights, but I used black matte nail polish right over the dash lights.Yup and that trick works great too for the service engine light in you vehicle.

Nice thing about using tape is that it could be cut perfectly and run right down the whole display to catch all of them at once.

I got the fine 1 micrometer scales because they didn't charge me to upgrade and because I was led to believe you could select the number of digits to display. I'm still looking for that option but it's not jumping off the page anyplace just yet..... I do hope it's there because it should round the last digit instead of truncating like the tape would do.

I got the fine 1 micrometer scales because they didn't charge me to upgrade and because I was led to believe you could select the number of digits to display. I'm still looking for that option but it's not jumping off the page anyplace just yet..... I do hope it's there because it should round the last digit instead of truncating like the tape would do.

Is the manual available on-line or can you post a copy? I can't control the number of displayed digits on mine either but the anti-vibration setting sure helps.Nice thing about using tape is that it could be cut perfectly and run right down the whole display to catch all of them at once.

I got the fine 1 micrometer scales because they didn't charge me to upgrade and because I was led to believe you could select the number of digits to display. I'm still looking for that option but it's not jumping off the page anyplace just yet..... I do hope it's there because it should round the last digit instead of truncating like the tape would do.

Yes, mine has an antivibration setting too. I can't really tell you how well it will work. I tested it briefly. The manual, says it's for non-mill type machines. On first blush it appears to lock the display until a big change comes along. Didn't like that.

I'll send you a PM with the manual when I get back home.

I'll send you a PM with the manual when I get back home.

I tried that. The distance measurent goes down.Set res to 5

Ie, the DRO reads 15 when it should say 3. The number of digits displayed does not change.