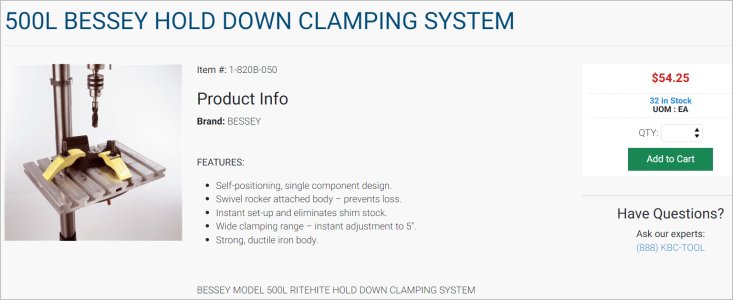

I need to get some T-nuts so I can clamp my vice to the mill table (once it’s back together…)

So in the vein of “in for a penny in for a pound”…

What’s the opinion on getting a set like this?

Am I wasting my money? I suspect if it’s too big to put in a vice, this is the next step.

(If I’m honest with myself, I think what attracts me to this set is the blue plastic holder…)

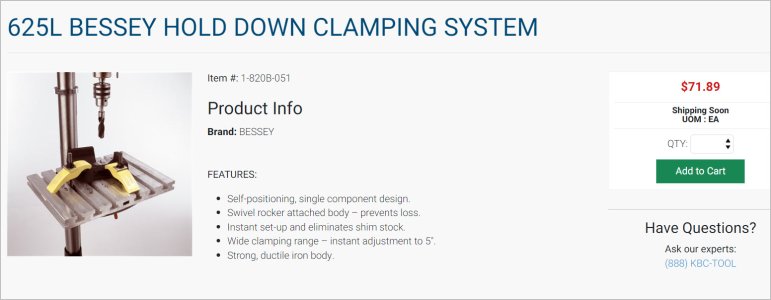

So in the vein of “in for a penny in for a pound”…

What’s the opinion on getting a set like this?

Am I wasting my money? I suspect if it’s too big to put in a vice, this is the next step.

(If I’m honest with myself, I think what attracts me to this set is the blue plastic holder…)