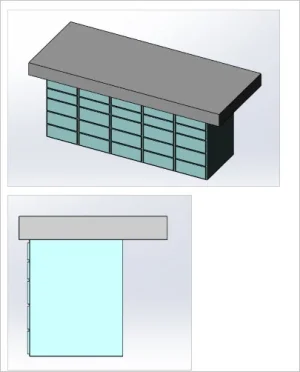

Been thinking about doing this for a while. When I built the shop 15ish years ago, I had access, at a very good price, to large windows (82 x 36") so put three in the shop. Thought it would be great! As much as it is nice, it robs a lot of of wall space. And I am starting to have concerns about the shop contents being too visible, especially when working at night. We are semi rural. One window got fully covered a couple of years ago with a sheet of plywood (don't miss the window at all) and this weekend, I got this done. I still have the options of opening it, but can close it up when I want. I also got rid of some of my materials pile. The cherry plywood was left over from a kitchen job I did a few years ago. That leaves one large window over the lathe to decide whether to do the same or not. That one will be missed more as it looks over the yard. The other ones just backed onto the treed property line.

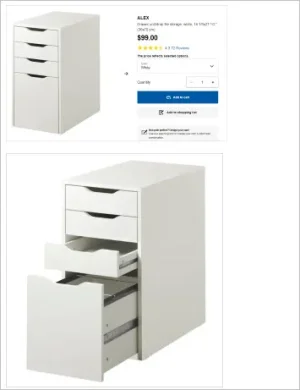

And that project lead to cleaning and reorganizing a bit too. The oil stains on the wall are from the old lathe that I had at one time. All in all, a good change so far.

And that project lead to cleaning and reorganizing a bit too. The oil stains on the wall are from the old lathe that I had at one time. All in all, a good change so far.