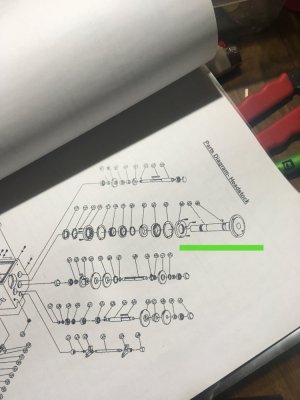

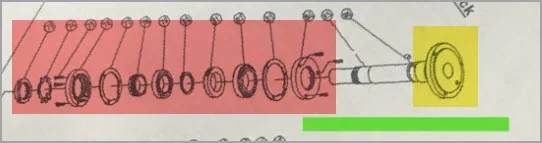

...green on the first this appears to show a one piece spindle with the backing plate, mt5 taper, and 1.5" thru hole as one, i will need access to a larger machine to make new holes, one reason i am steering away from an adapter plate is the loss of work space

'new holes' .... this is where I'm still confused.

- If you are saying new holes in a new adapter plate, that would be a mill or drill press work because the holes are perpendicular to the plate. You cant do that in a lathe. The plate OD/face/shoulder turning itself is done in-situ in the lathe starting with a semi machined blank. That guarantees that it is 100% concentric with your spindle. You mount the semi-machined blank on the spindle & turn it to whatever the (typically plain back) chuck dimensions requires. Then do the drilling.

- if you are talking about pulling the spindle & drilling new holes on the spindle nose section (yellow hilite)... well that's a different journey. Not only have you permanently altered a lathe that was set up to a specific standard, but you get to re-assemble all those bearings & re-establish the backlash fits etc. (pink shade).

This might not be obvious but when you buy a chuck, be it 3-jaw, 4-jaw, 5C collet...

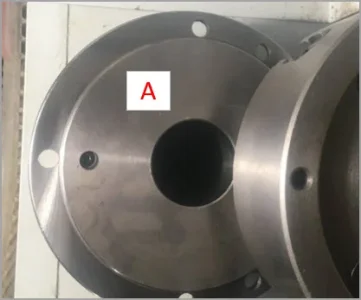

A) it can be an 'integrated' style, which means the back end is already completed to be directly mounted to a specific standard spindle nose. Maybe its a screw-on, or maybe D1-4, or maybe German ISO... there are probably 20 different standards out there depending on the machine. There is no changing these, they can only mount to that standard. Some prefer integrated because they are a bit more compact & they don't have a need to ever use it on a different spindle.

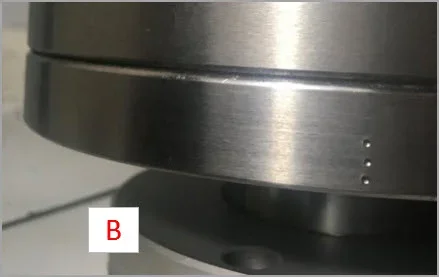

B) The chuck body itself could be essentially the same as A) but its already pre-married to a

removable adapter plate made to one of these spindle nose standards. If you take the adapter plate off, you are left with something like a plain back chuck that can be mounted to any another machine, providing to have the correct adapter plate which marries the 2 together. From what I can tell, this is your status - a chuck that needs a different plate to marry to your particular spindle. So I'm not suggesting 2 stacked adapter plates here, only one should be used but the 'correct' plate suited to your lathe. If that was properly packaged with your lathe, we probably wouldn't be having this discussion

Hope this helps