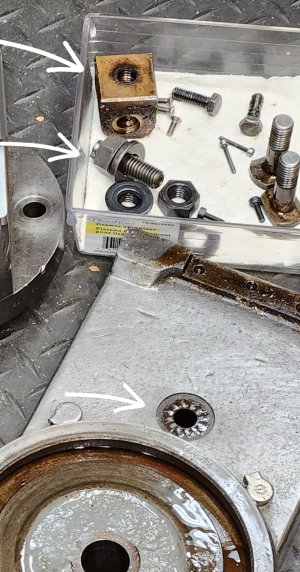

In the next couple weeks/months, I'm going to tackle making a new cross-slide lead-screw and nut. Not that there is anything terribly wrong with the existing units, I just want to do it for the experience, and hopefully get less than the 0.020" backlash it currently has.

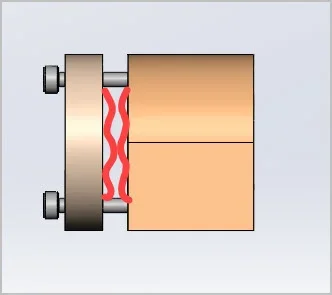

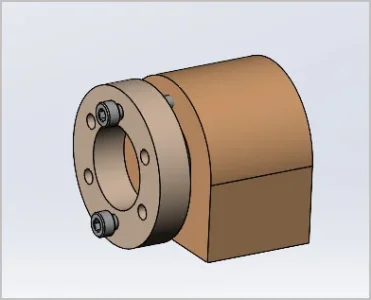

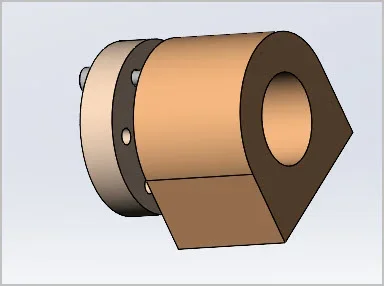

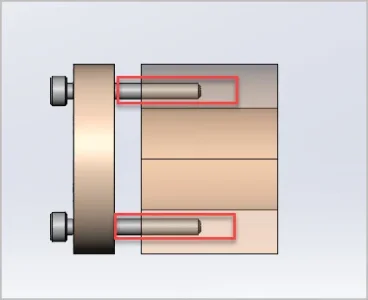

The lathe is a Standard Modern 1654 Utilathe. The cross-slide lead-screw is LH3/4"-5tpi Acme. My goal is to machine a tighter tolerance 4C (ceneralized) Acme thread for both the lead screw and the nut. The leadscrew shouldn't be an issue; the nut a little more difficult, but the most difficult part might be in the alignment of the two parts so that they won't bind. Maybe some sort of a floating or adjustable mount for the nut?

We'll address that hurdle when we get to it. In the meantime, I just ground a 3/8" HSS tool bit for the Acme form. I made the nose smaller than 5tpi, so that I can fine tune the thread.

The lathe is a Standard Modern 1654 Utilathe. The cross-slide lead-screw is LH3/4"-5tpi Acme. My goal is to machine a tighter tolerance 4C (ceneralized) Acme thread for both the lead screw and the nut. The leadscrew shouldn't be an issue; the nut a little more difficult, but the most difficult part might be in the alignment of the two parts so that they won't bind. Maybe some sort of a floating or adjustable mount for the nut?

We'll address that hurdle when we get to it. In the meantime, I just ground a 3/8" HSS tool bit for the Acme form. I made the nose smaller than 5tpi, so that I can fine tune the thread.